portable roll former

The Advantages of Portable Roll Formers

In the realm of modern construction and manufacturing, efficiency and versatility are paramount. One innovation that has gained significant traction in recent years is the portable roll former. This machine enables users to produce metal profiles on-site, thus enhancing both productivity and flexibility. This article explores the benefits, applications, and features of portable roll formers, shedding light on why they stand out as invaluable tools for contractors, manufacturers, and builders alike.

What is a Portable Roll Former?

A portable roll former is a specialized machine designed to shape metal sheets into specific profiles or shapes using a series of rolls. Unlike traditional roll formers, which can be bulky and fixed in place, portable roll formers are compact, lightweight, and designed for mobility. This allows them to be transported easily to various job sites, making them ideal for on-site construction applications.

Key Advantages

1. Mobility and Flexibility The most significant advantage of portable roll formers is their mobility. They can be transported easily to different project sites, allowing contractors to adjust to the demands of various jobs without the need for extensive pre-fabrication. This flexibility reduces downtime and enables teams to respond swiftly to changes in project scope.

2. Cost Efficiency By producing materials on-site, portable roll formers eliminate the need for transporting pre-made metal profiles. This can significantly reduce shipping costs and lead times. Additionally, on-demand production minimizes waste, as materials can be tailored precisely to the specifications required for each project.

3. Customization Portable roll formers allow for customization of metal profiles in real time. This adaptability is crucial in construction, where unique designs or modifications are often needed. Contractors can create custom shapes for flashing, trims, or even roofing systems to meet specific architectural requirements.

portable roll former

4. Reduced Labor Requirements The use of a portable roll former can streamline operations by reducing the number of workers needed for material handling and assembly. With an efficient roll former, fewer personnel are required to manage the production process, allowing teams to allocate their labor to other critical tasks.

5. High-Quality Output Advances in technology have made portable roll formers capable of producing high-quality profiles with precision. This ensures that the finished products meet the necessary standards and specifications, which is essential for durability and structural integrity in construction.

Applications

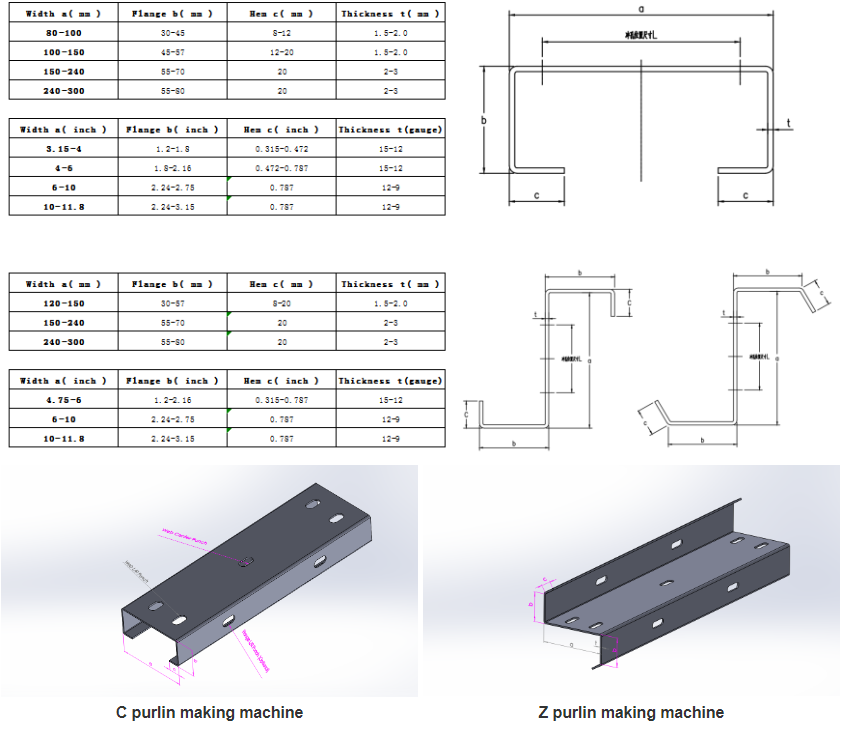

Portable roll formers have a wide range of applications across various industries. They are particularly popular in roofing and siding applications, where contractors need to create metal panels on-site. Other applications include the production of metal flashing, purlins, gutters, and a host of custom profiles for architectural features. Their versatility makes them suitable for both residential and commercial constructions.

Features to Consider

When selecting a portable roll former, there are several features to consider - Transportability Consider the weight and size of the unit. Models that can easily fit into standard vehicles are ideal for contractors on the go. - Ease of Use User-friendly controls and setup processes can significantly enhance efficiency and reduce the learning curve for new operators. - Durability A well-built roll former should withstand the rigors of various job sites, including exposure to different weather conditions. - Versatility Look for models that can handle a range of materials and profiles to maximize utility.

In conclusion, the portable roll former is an innovative solution that caters to the modern requirements of the construction industry. By providing mobility, cost-effectiveness, customization, and high-quality output, these machines empower contractors to optimize their workflows and deliver superior results. As construction methods continue to evolve, portable roll formers are poised to play an increasingly vital role in shaping the industry's future.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025