Pipe Roll Forming Manufacturing Facility for High-Quality Production

The Evolution and Importance of Pipe Roll Forming Factories

In the realm of manufacturing, few processes are as efficient and intricate as roll forming. Among the various applications of this versatile technique, pipe roll forming has emerged as a critical process in producing high-quality pipes for numerous industries. This article delves into the workings of pipe roll forming factories, their significance in modern manufacturing, and the technology driving this innovative process.

Understanding Pipe Roll Forming

Roll forming is a continuous bending process that transforms flat metal sheets into specific shapes or profiles. Pipe roll forming specifically focuses on creating pipes by gradually shaping metal strips through a series of rollers, each designed to perform a particular task in the formation process. The result is a seamless, uniform pipe that boasts superior strength and durability compared to traditional welding methods.

The process begins with a metal strip, often made from steel, aluminum, or other alloys. This strip is fed through a series of rollers that progressively form the material into the desired pipe shape. As the strip continues through the roll forming line, each set of rollers bends and shapes the metal until it exits as a fully formed pipe. This process not only enhances efficiency but also minimizes waste, making it an environmentally friendly option for manufacturers.

Advantages of Pipe Roll Forming

One of the key advantages of pipe roll forming is the consistency and precision it offers. The automated nature of the process allows for tight tolerances, ensuring that each pipe produced meets stringent quality standards. This consistency is vital in industries such as construction, automotive, and aerospace, where reliability and safety are paramount.

Additionally, pipe roll forming is capable of producing a wide range of pipe sizes and shapes to meet diverse applications. Whether it’s round, square, or rectangular, manufacturers can customize their products to suit specific requirements. This flexibility allows companies to cater to niche markets and adapt quickly to changing consumer demands.

Furthermore, producing pipes through roll forming is typically faster than traditional methods. The continuous nature of the process means that large quantities can be produced in a short amount of time, making it ideal for high-volume manufacturing scenarios. This rapid production capability helps companies reduce lead times and enhance their competitiveness in the marketplace.

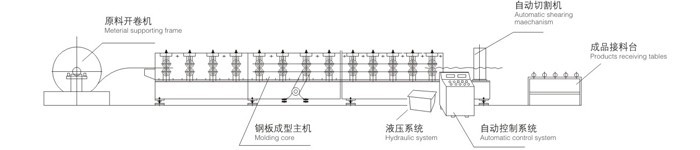

pipe roll forming factory

Technological Advancements in Pipe Roll Forming

The evolution of technology has significantly influenced the pipe roll forming industry. Modern factories are equipped with advanced machinery that incorporates computer numerical control (CNC) systems, enabling precise control over the shaping process. This technology allows for real-time adjustments, ensuring that any variations in material properties can be addressed on the fly.

Moreover, the integration of automation and robotics in pipe roll forming factories has further enhanced efficiency. Automated systems can handle material transportation, feeding, and even quality inspection, reducing the reliance on manual labor and minimizing human error. As a result, manufacturers can achieve higher productivity levels while maintaining quality control.

Environmental Considerations

In an era where sustainability is paramount, pipe roll forming factories are increasingly adopting eco-friendly practices. The reduction of waste inherent in the roll forming process is complemented by the use of recyclable materials. Many manufacturers are now sourcing recycled metals and implementing closed-loop systems that minimize their carbon footprint.

Additionally, advancements in energy-efficient machinery have contributed to reducing energy consumption during production. By adopting greener practices, pipe roll forming factories can meet the demands of environmentally-conscious consumers while positioning themselves as responsible industry players.

Conclusion

Pipe roll forming factories play a pivotal role in contemporary manufacturing, delivering high-quality, precise, and sustainable products across various industries. As technology continues to advance, these factories will likely evolve further, embracing innovations that enhance efficiency and environmental responsibility. For businesses and consumers alike, investing in the capabilities of pipe roll forming represents a commitment to quality, sustainability, and forward-thinking manufacturing practices. From construction sites to automotive plants, the impact of roll-formed pipes will undoubtedly shape the future of industrial applications.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025