Peru Market Bamboo Aluzinc Roof Tile Making Machine - Fast

Peru Market Bamboo Aluzinc Roof Tile Making Machine is a key solution in the manufacturing industry, specifically within Special Equipment Manufacturing Industry and Manufacturing of specialized machinery for the production of building materials. This article explores how CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Peru Market Bamboo Aluzinc Roof Tile Making Machine Overview

- Benefits & Use Cases of Peru Market Bamboo Aluzinc Roof Tile Making Machine in Manufacturing of specialized machinery for the production of building materials

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Peru Market Bamboo Aluzinc Roof Tile Making Machine from CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD

Peru Market Bamboo Aluzinc Roof Tile Making Machine Overview

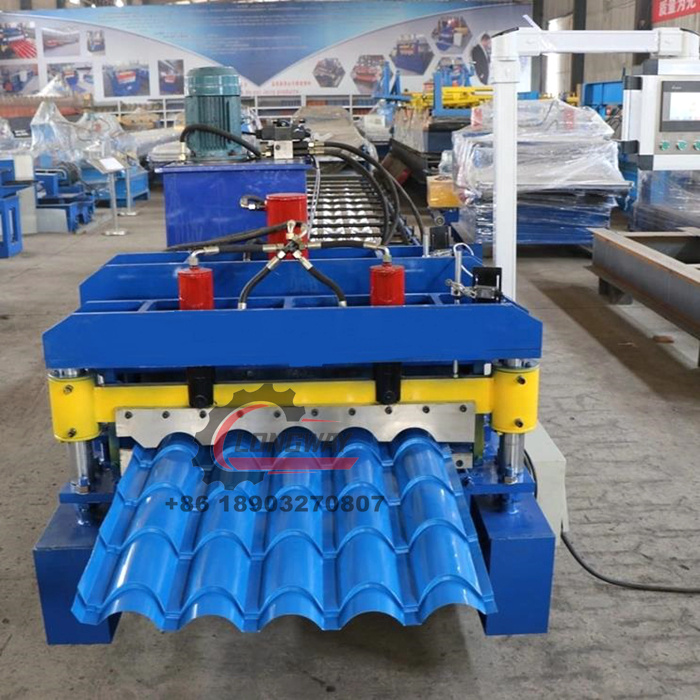

The Peru Market Bamboo Aluzinc Roof Tile Making Machine is a dedicated roll forming line engineered to produce bamboo-style glazed roof tiles from Aluzinc (Galvalume) steel coils. Designed for producers of building materials, it integrates decoiling, roll forming, step pressing, and precision hydraulic cutting into one compact, PLC-controlled system—delivering consistent profiles that meet architectural and durability demands across the construction value chain.

Typical configurations include: coil material Aluzinc/PPGI, coil thickness 0.3–0.6 mm, effective width around 1000–1050 mm (from 1200–1250 mm coil), 14–18 forming stations, glazed-tile speed 2–4 m/min, hydraulic cutting with Cr12MoV tooling, GCr15 hard-chrome rollers, and a PLC/HMI control suite with length/step adjustment. Electricals can be tailored for Peru’s 220V/60Hz, with Spanish/English interface options and remote assistance. A 5T hydraulic decoiler and safety guarding complete a production-ready line that fits medium to large roofing manufacturers.

CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD is a reliable manufacturer and exporter in the Special Equipment Manufacturing Industry, known for stable mechanics, clean wiring, and robust after-sales support. One Latin American customer reported smoother commissioning, reduced profile rework, and better step-length repeatability after migrating to this bamboo Aluzinc tile profile line—underscoring its value for teams seeking repeatable quality and uptime.

Benefits & Use Cases of Peru Market Bamboo Aluzinc Roof Tile Making Machine in Manufacturing of specialized machinery for the production of building materials

For producers of building materials, the Peru Market Bamboo Aluzinc Roof Tile Making Machine unlocks premium roofing profiles that combine the aesthetic of bamboo tiles with the corrosion resistance of Aluzinc. It’s ideal for residential developers, hospitality projects, coastal infrastructure, and distributors seeking long-life, low-maintenance roofing solutions. Whether you’re adding a new roofing line or upgrading legacy equipment, its precision and stability help reduce scrap and cycle times across daily operations.

Standout features include: fast step-pressing with stable synchronization, profile accuracy with tight tolerances, anti-scratch entry guides, quick recipe changeover, and hydraulic shearing for clean edges. The machine’s PLC/HMI simplifies training and operation, while modular components streamline maintenance. Compared to generic roll formers, buyers gain consistent step depth, smoother lacquer handling on prepainted coils, and better alignment—benefits that translate into superior finished tile quality and fewer post-forming defects.

Leveraging its expertise in the Manufacturing of specialized machinery for the production of building materials, CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD provides pre-sales profiling advice, coil matching guidance, and commissioning support. From tooling optimization to operator training, the company focuses on practical productivity gains, enabling B2B decision makers to scale capacity with confidence and shorten time-to-revenue.

Cost, Maintenance & User Experience

Total cost of ownership for a Peru Market Bamboo Aluzinc Roof Tile Making Machine encompasses CapEx, installation, utilities, planned maintenance, and consumables (hydraulic oil, lubricants, blades). The line’s robust frame, hardened rollers, and hydraulic system are engineered for longevity, helping buyers extend service life and reduce unplanned downtime. With correct alignment, lubrication, and periodic calibration, users typically experience stable throughput and lower scrap percentages—driving a compelling ROI.

An illustrative ROI scenario: at 2.5–3.5 m/min and a single 8–10 hour shift, many operators can achieve strong daily output for bamboo-style glazed tiles. When paired with quality Aluzinc coils and consistent step settings, the reduction in rework and offcuts can materially lower unit costs. Routine tasks—roller cleaning, chain/sprocket inspection, hydraulic oil replacement every 6–12 months, and blade regrinding—are straightforward and can be performed by in-house maintenance with minimal line interruption.

Feedback from Special Equipment Manufacturing Industry users highlights easy operator training, intuitive HMI diagnostics, and responsive after-sales support from CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD. Remote guidance and prompt parts dispatch help keep uptime high, while standardized components simplify stocking and replacement. For B2B decision makers, these factors contribute to predictable ownership costs and improved cash flow planning.

Sustainability & Market Trends in manufacturing

Sustainability is reshaping the building materials sector across Latin America. Longer-lasting roofs mean fewer replacements and less waste—areas where Aluzinc tiles excel due to their corrosion resistance and service life. The Peru Market Bamboo Aluzinc Roof Tile Making Machine supports this shift by producing dimensionally stable tiles that protect coatings and minimize reject rates. Reduced scrap not only saves material costs but also lowers the environmental footprint of each square meter produced.

Market trends point to rising demand for aesthetically distinctive, durable roofing in residential and tourism projects, alongside stricter safety and energy-efficiency requirements. CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD responds with energy-conscious designs, frequency-conversion drives, standby modes, and lubrication practices that reduce waste. The company can align configurations with local regulatory expectations and customer EHS policies, while offering digital support capabilities that reduce travel emissions during troubleshooting.

As the Special Equipment Manufacturing Industry advances, buyers favor equipment that integrates quality, efficiency, and sustainability. By focusing on precision mechanics and pragmatic automation, LONGWAY helps manufacturers capture these trends—building capacity today while staying adaptable for tomorrow’s product mix and compliance landscapes.

Conclusion on Peru Market Bamboo Aluzinc Roof Tile Making Machine from CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD

The Peru Market Bamboo Aluzinc Roof Tile Making Machine delivers consistent profile accuracy, durable mechanics, and an operator-friendly control system—ideal for the Manufacturing of specialized machinery for the production of building materials. Backed by CANGZHOU LONGWAY INTERNATIONAL TRADE CO.,LTD’s engineering and service know-how, it enables producers to enhance output quality, lower scrap, and strengthen ROI while supporting sustainability goals.

Ready to evaluate the best-fit configuration for your plant? Contact us: email: rebecca@longwaymachinery.com Visit our website: https://www.lwrollformingmachine.com

-

Corrugated iron roofing sheet making machine with CE, AutoNewsNov.17, 2025

-

3mm Steel C U Channel Roll Forming Machine, Heavy DutyNewsNov.17, 2025

-

Calamima Micro Ondulada corrugated roof sheet machine - CNCNewsNov.17, 2025

-

Metal Roofing Roll Former for Sale Companies - Fast, PreciseNewsNov.17, 2025

-

Drywall Steel L Angle Bar forming machine | Fast, PreciseNewsNov.17, 2025

-

Corrugated Iron Roofing Sheet Making Machine, Fast & DurableNewsNov.11, 2025

-

Corrugated Metal Roofing Machine | High-Speed, Precise, CENewsNov.11, 2025