PBR Roof Panel Production Equipment for Efficient Structural Solutions

Enhanced Efficiency and Durability with PBR Roof Panel Machines

In the ever-evolving construction industry, the demand for durable and efficient building materials has intensified significantly. One of the most innovative solutions that have emerged in recent years is the PBR roof panel machine. This state-of-the-art equipment is designed to produce PBR (Purlin Bearing Rib) roof panels, which are increasingly popular due to their structural integrity, aesthetic appeal, and ease of installation.

What is a PBR Roof Panel?

PBR roof panels are metal sheets characterized by their unique ribbed design, which includes raised ribs that run along the length of the panel. This design not only enhances their structural strength but also provides excellent water drainage, making them ideal for various weather conditions. The versatility of PBR roof panels makes them suitable for a range of applications, including commercial buildings, warehouses, and agricultural facilities.

Significance of PBR Roof Panel Machines

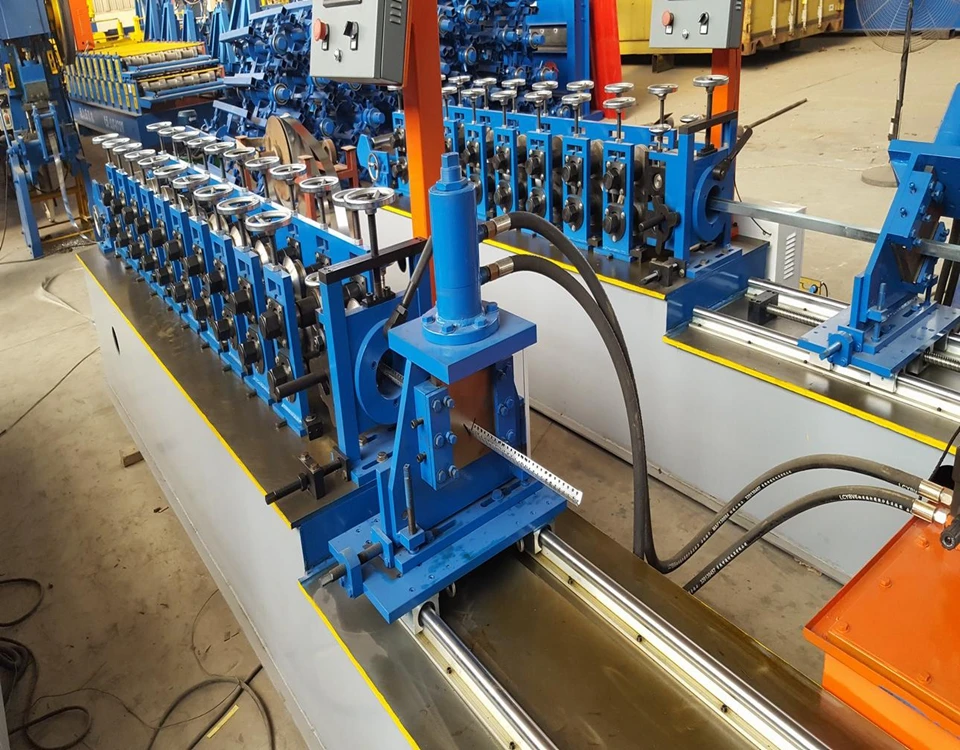

PBR roof panel machines are critical for any manufacturer aiming to capitalize on the growing demand for these roofing materials. The machines automate the process of cutting and forming metal sheets into PBR panels, ensuring high precision and consistency in production. This automation leads to increased efficiency, as manufacturers can produce large volumes of panels in a shorter time while minimizing labor costs.

The machines come equipped with advanced technology that allows for easy adjustments to panel specifications, such as width, length, and rib height. This feature enables manufacturers to meet the specific requirements of their clients without the need for extensive retooling or downtime. Furthermore, modern PBR roof panel machines often incorporate computer numerical control (CNC) systems, which enhance production accuracy and allow for intricate designs to be easily replicated.

Benefits of Using PBR Roof Panel Machines

pbr roof panel machine

1. Durability and Strength One of the primary advantages of PBR roof panels is their ability to withstand harsh environmental conditions, such as heavy snowfall, strong winds, and intense rain. The robust design of the panels, combined with the precision manufacturing process facilitated by PBR roof panel machines, ensures longevity and minimal maintenance.

2. Cost-Efficiency With the automated production capabilities of PBR roof panel machines, manufacturers can significantly reduce labor costs while increasing output. Additionally, the quick installation process of PBR panels translates to lower labor expenses at the construction site, providing a compelling economic advantage.

3. Versatility PBR roof panels can be used across various sectors, providing manufacturers with a broad market base. Their aesthetic appeal allows them to be incorporated into various architectural styles, further expanding their applicability.

4. Eco-Friendly Options Many PBR roof panel machines are designed to accommodate recycled materials, supporting sustainable construction practices. The use of metal roofing is also notable for its energy efficiency, reflecting heat and helping to lower cooling costs in buildings.

5. Simplicity of Installation The design of PBR roof panels allows for easy interlocking and fastening, which simplifies the installation process. Consequently, this reduces the overall project timeline and ensures that structures can be secured promptly and efficiently.

Conclusion

The advent of PBR roof panel machines marks a significant advancement in the roofing industry. By offering manufacturers the ability to produce high-quality, durable, and cost-effective roofing solutions, these machines are transforming how we approach construction. As the demand for top-tier building materials continues to rise, investing in PBR roof panel machines will undoubtedly provide competitive advantages, ensuring that businesses remain at the forefront of the market. By embracing this technology, manufacturers can not only meet customer expectations but also contribute positively to the industry’s sustainability and efficiency goals.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025