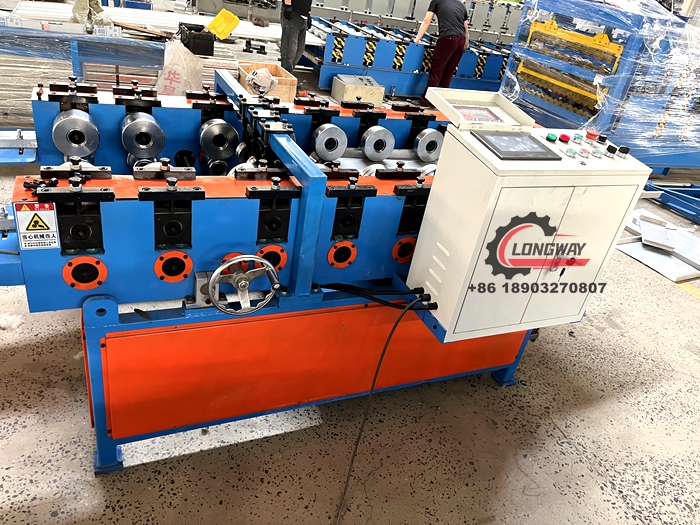

pbr roll former company

Exploring PBR Roll Former Companies Innovations and Industrial Impact

In the realm of modern manufacturing, PBR roll forming plays a critical role in the production of high-quality metal components used in a wide array of applications, from construction to automotive industries. PBR, or Panel with Battened Rib, is a specific type of metal roofing panel that is renowned for its strength, durability, and aesthetic appeal. Companies specializing in PBR roll forming offer advanced technology and innovative solutions that meet the diverse needs of today's market.

Exploring PBR Roll Former Companies Innovations and Industrial Impact

One of the standout features of PBR roll former companies is their commitment to customization. Given the variabilities in architectural designs and construction requirements, these companies offer tailored solutions that meet specific customer needs. Clients can select various gauges, colors, and finishes to ensure compatibility with their projects. Whether it’s a commercial building, residential home, or industrial facility, PBR roll forming manufacturers provide solutions that balance functionality with aesthetic appeal.

pbr roll former company

Moreover, sustainability has become a pressing concern in recent years, and PBR roll forming companies are responding by adopting environmentally friendly practices. Many manufacturers incorporate recycled materials in their production processes, and the durability of PBR panels contributes to longer lifespans, reducing the need for frequent replacements. Additionally, the energy efficiency of metal roofing systems can lead to reduced energy consumption for heating and cooling, further emphasizing a commitment to sustainable practices.

In the competitive landscape of manufacturing, PBR roll former companies are also leveraging advancements in technology. Automation and digitalization have streamlined the production process, enhancing precision and reducing turnaround times. Cutting-edge software enables these companies to optimize their designs and manage inventory effectively, resulting in cost savings and improved customer satisfaction. With the integration of Industry 4.0 principles, manufacturers are able to bring more innovative solutions to market while maintaining quality.

The significance of PBR roll forming extends beyond individual projects; it boosts local and national economies as well. By producing high-quality materials domestically, these companies create jobs and contribute to the local economy. Moreover, the global export of PBR products fosters international trade relationships, highlighting the role of these companies in a broader economic context.

In conclusion, PBR roll former companies are at the forefront of modern manufacturing, providing versatile, durable, and aesthetically pleasing products that cater to a wide variety of industries. Their commitment to innovation, customization, and sustainability positions them as key players in the construction and manufacturing sectors. As the demand for efficient, high-quality metal components continues to grow, these companies will undoubtedly play an essential role in shaping the future of manufacturing and industrial design. As they evolve and adapt to new challenges and opportunities, the influence of PBR roll former companies will only become more pronounced in the years to come.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025