Tinglado Panel Production Machine for Efficient Structural Forming and Assembly

The Evolution and Significance of Panel Tingleado Forming Machines

In the modern manufacturing landscape, efficiency and precision take precedence over traditional methods. Among the myriad of innovative technologies, panel tingleado forming machines stand out as crucial tools in the production of metal panels, particularly in the construction and automotive industries. These machines are designed to create intricate patterns and shapes from flat metal sheets, allowing for a wide range of applications in the fabrication of building materials, automotive body parts, and more.

Understanding Panel Tingleado Forming Machines

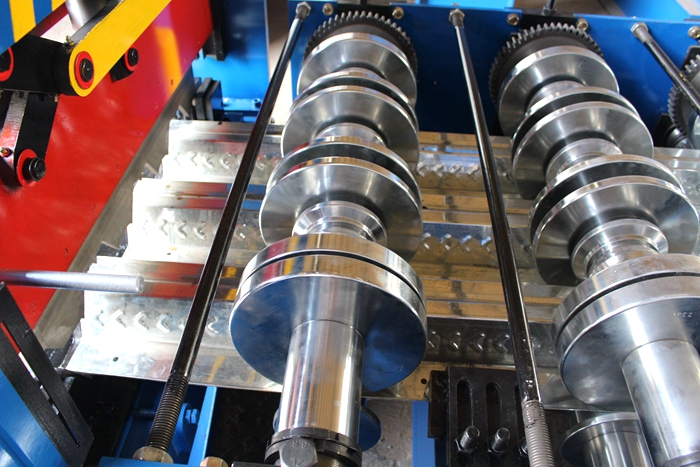

Panel tingleado forming machines operate through a process known as roll forming. This method involves feeding a strip of flat metal through a series of rollers that gradually shape it into the desired profile. The term tingleado refers to the specific design or pattern that is created on the metal surface. This technique not only enhances the aesthetic appeal of the panels but also increases their structural integrity.

The machines are highly versatile, capable of producing panels in various sizes, thicknesses, and materials, including steel, aluminum, and other alloys. This adaptability makes them invaluable for manufacturers who need to cater to diverse client needs and specific project requirements.

Key Features and Technology

Modern panel tingleado forming machines are equipped with advanced technology that allows for greater automation and precision in the manufacturing process. Features such as computerized control systems enable operators to program intricate designs, ensuring that every panel meets exact specifications. This level of automation reduces the potential for human error and enhances production speed, allowing companies to meet tight deadlines without sacrificing quality.

Many machines also come with built-in safety features, such as emergency stop buttons and protective shields, ensuring that operators can work confidently and safely. Additionally, improvements in energy efficiency mean that contemporary machines consume less power, aligning with global efforts toward sustainable manufacturing practices.

panel tinglado forming machine

Applications of Panel Tingleado Forming Machines

The applications of panel tingleado forming machines are extensive. In the construction industry, they are used to fabricate roofing and wall panels that not only provide structural support but also contribute to the aesthetic value of buildings. The patterns created by these machines can enhance the visual appeal of a structure, making it more attractive to potential tenants or buyers.

In the automotive sector, panel tingleado machines are instrumental in crafting body parts that require both durability and design integrity. The ability to produce lightweight, yet strong components means that manufacturers can achieve better fuel efficiency in vehicles without compromising safety.

Future Trends

As technology continues to advance, the panel tingleado forming machine industry will likely see significant innovations. Integration with Industry 4.0 concepts, such as the Internet of Things (IoT), is anticipated to revolutionize how these machines operate. Sensors and data analytics will provide real-time insights into the manufacturing process, enabling predictive maintenance and minimizing downtime.

Additionally, the push towards eco-friendly materials will drive the development of forming machines capable of processing new, sustainable resources. Manufacturers will increasingly look to adopt practices that minimize waste and energy consumption, ultimately leading to a more sustainable production cycle.

Conclusion

In conclusion, panel tingleado forming machines exemplify the intersection of technology and manufacturing efficiency. Their ability to produce high-quality, intricate designs with speed and precision positions them as indispensable assets across multiple industries. As advancements in technology continue to unfold, the potential for these machines will expand, further enhancing the capabilities of manufacturers worldwide. Consequently, embracing these innovations not only supports business growth but also contributes to a more sustainable and efficient future in manufacturing.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025