On-Site Roll Forming Solutions for Custom Metal Fabrication Services

On-Site Roll Forming A Game Changer for Construction and Manufacturing

In the fast-evolving landscape of construction and manufacturing, efficiency, precision, and adaptability are paramount. One innovative solution that has gained significant traction in recent years is on-site roll forming. This technique has redefined how metal fabrication is executed, offering numerous advantages that traditional methods cannot match.

What is On-Site Roll Forming?

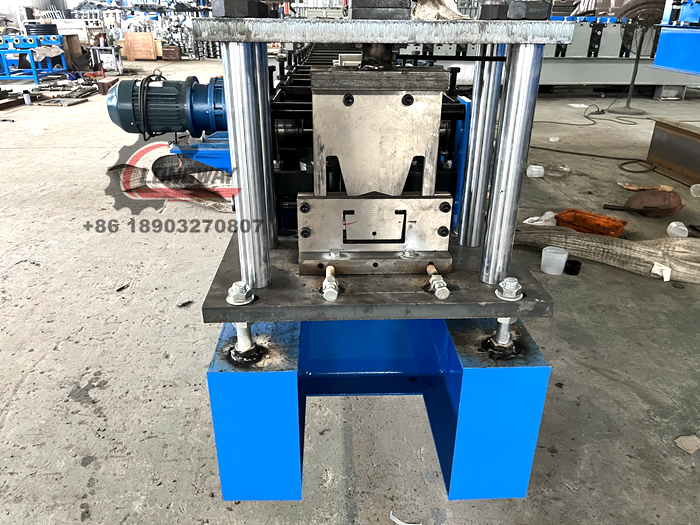

On-site roll forming is a process where metal sheets or coils are transformed into custom shapes and profiles directly at the job site using specialized machinery. Unlike traditional fabrication methods, which involve cutting and assembling components in a factory setting, on-site roll forming eliminates the need for extensive pre-fabrication. This method allows for immediate customization based on the project's unique requirements, resulting in a more streamlined workflow.

Advantages of On-Site Roll Forming

1. Reduced Lead Times One of the most significant advantages of on-site roll forming is the reduction in lead times. Since the forming process occurs at the construction site, there's no need to wait for fabricated materials to be delivered from a distant factory. This efficiency accelerates project timelines, helping contractors meet deadlines and stay within budget.

2. Customization Every construction project has its own set of specifications and demands. On-site roll forming allows for real-time adjustments to the design, enabling contractors to create components that meet exact requirements. Whether it involves unique shapes or specific dimensions, this flexibility is crucial in today's diverse construction environment.

3. Waste Reduction Traditional manufacturing often results in excess material waste. On-site roll forming minimizes this waste by producing only what is necessary for the project. Moreover, as the forming takes place on location, any leftover material can often be repurposed on-site, contributing to a more sustainable construction process.

on site roll forming company

4. Cost-Effectiveness While the initial investment in roll forming equipment may seem high, the long-term savings are significant. Reduced labor costs, decreased material waste, and faster project turnaround times all contribute to the overall cost-effectiveness of on-site roll forming. Additionally, fewer delays in supply chains mean fewer unexpected expenses.

5. Improved Quality Control When production occurs on-site, quality control becomes more manageable. Contractors can monitor the forming process in real-time, ensuring that every profile meets strict quality standards. This oversight reduces the likelihood of defects and ensures that the final product aligns with the project’s vision.

6. Mobility and Flexibility On-site roll forming equipment is designed to be portable. This mobility allows contractors to easily move the machinery to different locations as needed, adapting to various job sites and project demands without the constraints of fixed facilities.

Applications in Various Industries

On-site roll forming has found applications across multiple industries, including commercial construction, residential building, and even specialized sectors like roofing and automotive manufacturing. In commercial construction, it allows for the rapid creation of steel studs, tracks, and other structural components. The roofing industry benefits from the ability to produce bespoke flashing and trim profiles directly on-site, ensuring a perfect fit.

Conclusion

As the construction and manufacturing industries continue to embrace technological advancements, on-site roll forming stands out as a significant innovation. By reducing lead times, allowing for customization, decreasing waste, and offering cost-saving benefits, this method is reshaping the way projects are conceived and executed. With its growing popularity and proven advantages, on-site roll forming is not just a trend; it is a game changer that enhances efficiency and quality in the building process. As we move towards a more dynamic and responsive approach to construction, on-site roll forming will undoubtedly play a pivotal role in the industry's future.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025