omega roll forming machine manufacturer

Understanding Omega Roll Forming Machines A Manufacturer’s Perspective

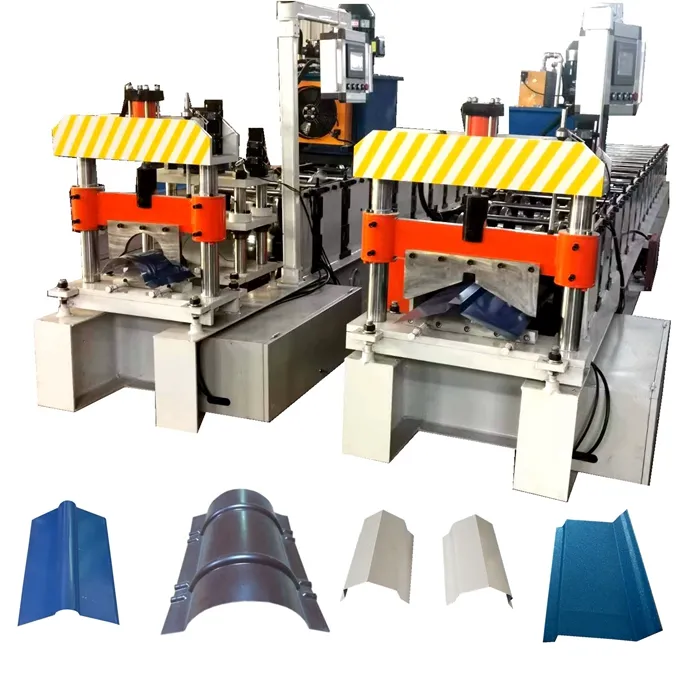

In the vibrant world of metal forming technology, omega roll forming machines stand out as crucial equipment used to produce high-quality metal profiles. These machines are designed to create omega-shaped profiles from various materials, particularly steel and aluminum. Their application is widespread across industries, including construction, automotive, and manufacturing. As a manufacturer of omega roll forming machines, understanding the nuances of this specialized equipment can provide a competitive edge in the marketplace.

What is Omega Roll Forming?

Roll forming is a continuous bending operation in which strips of metal are passed through sets of rolls to gradually shape them into the desired profiles. The omega profile, characterized by its unique shape resembling the Greek letter omega (Ω), is popular due to its structural advantages. It is particularly favored for use in applications where rigidity and light weight are necessary. This includes everything from support structures in buildings to components in furniture.

Key Features of Omega Roll Forming Machines

1. Precision Engineering One of the hallmark features of omega roll forming machines is their precision. High-quality machines come equipped with advanced control systems that ensure each profile is formed accurately, maintaining tight tolerances. This precision is essential for applications requiring exact specifications.

2. Versatility A well-designed omega roll forming machine can handle various materials and thicknesses, making it versatile and adaptable to different manufacturing needs. Manufacturers often seek machines that can easily switch between different profiles without requiring extensive reconfiguration.

3. High Production Efficiency Omega roll forming machines are designed for continuous operation, contributing to high production rates. The automated features in modern machines allow manufacturers to achieve consistent output while minimizing manual labor, further enhancing efficiency.

4. Durability and Reliability Given the rigorous demands of industrial applications, the structural integrity of roll forming machines is crucial. Reliable machines are constructed using high-quality materials and are designed to withstand the wear and tear of constant use.

omega roll forming machine manufacturer

The Manufacturing Process

The manufacturing process of omega roll forming machines involves several key stages

- Design and Engineering Before production, comprehensive design plans are created using advanced CAD software. This stage focuses on optimizing the forming rolls and ensuring that the machine can produce the desired omega profile efficiently.

- Fabrication The machine's components are fabricated using high-quality steel and other materials to ensure durability. Precision cutting and machining processes are employed to create each part to exact specifications.

- Assembly Once fabricated, these components are assembled to create the final machine. This stage often involves integrating advanced electronics for automation and control.

- Testing After assembly, machines undergo rigorous testing to ensure they meet performance and safety standards. This step is crucial to guarantee that the equipment will operate efficiently under production conditions.

The Future of Omega Roll Forming Machines

As industries continue to evolve, the demand for efficient and flexible manufacturing solutions is increasing. The future of omega roll forming machines is likely to see advancements in technology that enhance automation and integration with digital systems, such as Industry 4.0 capabilities.

In conclusion, as a manufacturer of omega roll forming machines, understanding these key aspects can significantly impact your business success. Focused investment in precision engineering, versatility, and durability, coupled with staying attuned to industry trends, will ensure that your offerings remain competitive in a fast-paced market. The omega roll forming machine is not just a tool but a vital ally in driving innovations and efficiencies within the manufacturing landscape.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025