omega estruc techo metalcon forming machine manufacturer

The Importance of Omega Strut, Metal Stud, and Forming Machines in Modern Construction

In the ever-evolving world of construction, efficiency and precision are of utmost importance. Among the numerous components that contribute to a successful building project, omega struts and metal studs stand out for their versatility and strength. As the need for innovative building solutions grows, the demand for advanced forming machines capable of producing these critical components has surged. In this article, we will explore the significance of omega struts, metal studs, and the manufacturing technology that drives their production.

Understanding Omega Struts and Metal Studs

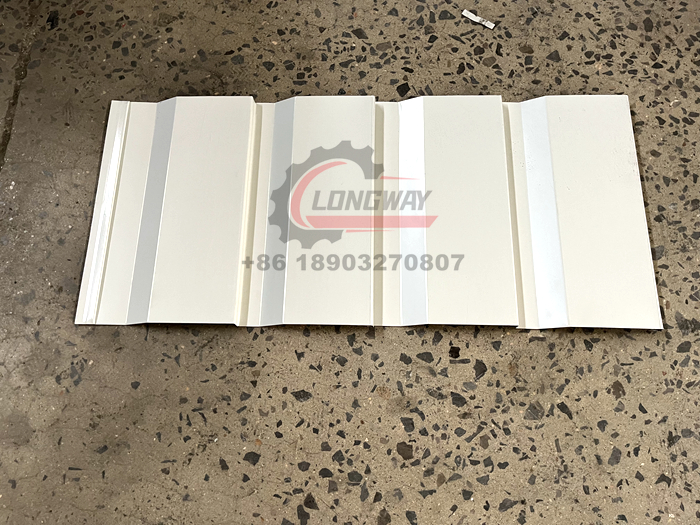

Omega struts are uniquely designed structural elements that provide exceptional support and stability in various construction projects. Their omega-shaped profile allows for enhanced load-bearing capacity while maintaining a lightweight structure. This makes them an ideal choice for both residential and commercial applications, where strength and weight considerations are crucial.

Similarly, metal studs have become a preferred choice for framing in modern construction. Traditionally made from steel, these studs offer numerous advantages over wooden alternatives, including resistance to warping, pests, and fire. The use of metal studs can significantly reduce the overall weight of a structure, allowing for more extensive builds and innovative designs.

The Role of Forming Machines

To meet the increasing demand for omega struts and metal studs, manufacturers have developed specialized forming machines. These machines are designed to create high-quality metal components with remarkable precision and efficiency. As a leading manufacturer of forming machines, the importance of innovation in technology cannot be overstated.

Forming machines utilize advanced techniques to transform flat metal sheets into complex profiles. This process often involves several stages, including shearing, bending, and punching. As a result, manufacturers can produce customized and intricate designs that cater to specific building requirements. By streamlining the production process, forming machines help reduce production time and labor costs, ultimately benefiting both manufacturers and end-users.

The Benefits of Advanced Technology

omega estruc techo metalcon forming machine manufacturer

The latest advancements in forming machine technology have revolutionized the production of omega struts and metal studs. Automated systems equipped with Computer Numerical Control (CNC) technology allow for greater accuracy in shaping and measuring. This ensures that the resulting components meet strict industry standards and enhances overall structural integrity.

Moreover, new forming machines are capable of producing multiple profiles in a single run, further increasing efficiency. This versatility means that manufacturers can respond quickly to changing market demands without the need for extensive retooling. As a result, construction companies benefit from shorter lead times and reduced project delays, leading to increased customer satisfaction.

Sustainability in Construction

Sustainable building practices are becoming increasingly important in today’s construction landscape. Utilizing components like omega struts and metal studs contributes to more sustainable design by minimizing waste and maximizing material efficiency. Metal, being recyclable, ensures that construction projects are not only strong and durable but also environmentally friendly.

In addition, the energy-efficient capabilities of forming machines play a significant role in reducing the carbon footprint of manufacturing processes. By optimizing material usage and reducing scrap, manufacturers can produce high-quality components while adhering to sustainable practices.

Conclusion

The intersection of omega struts, metal studs, and advanced forming machine technology is paving the way for a new era in construction. As builders seek more efficient, reliable, and sustainable solutions, the importance of these components cannot be overstated. Manufacturers of forming machines are at the forefront of this transformation, providing innovative tools that enhance production capabilities and meet the dynamic needs of the construction industry.

As technology continues to evolve, we can expect even more innovative solutions that will redefine building practices, ensuring that the structures of tomorrow are not only stronger but also more sustainable than ever before.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025