omega estruc techo metalcon forming machine factories

The Rise of Omega Estruc Techo Metalcon Forming Machines

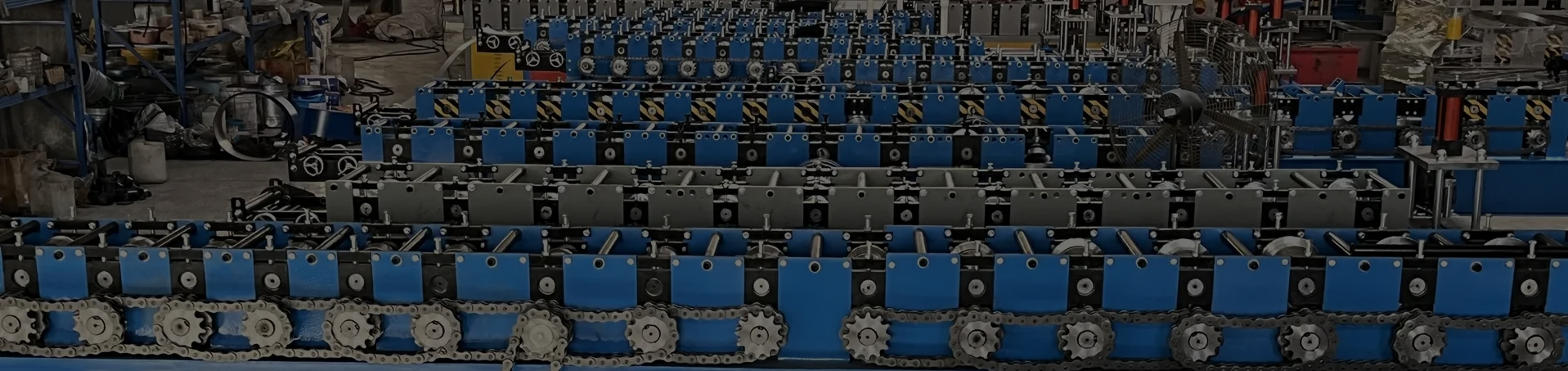

In the realm of modern construction, the demand for efficient and versatile building solutions has never been higher. Among the innovative technologies shaping this industry, Omega Estruc Techo Metalcon forming machines stand out as a game changer. These machines are designed specifically for producing metal framing components that are essential in the construction of residential and commercial buildings.

Omega Estruc Techo, a leader in the manufacturing of metal forming machines, has revolutionized the way builders approach structural framing. The Metalcon forming machine is engineered to enhance efficiency, reduce labor costs, and increase the quality of the end product. With its state-of-the-art technology, it offers a seamless solution for producing high-quality steel components, enabling faster construction times and improved structural integrity.

Key Features and Benefits

One of the most significant advantages of Omega Estruc Techo Metalcon forming machines is their precision. These machines are equipped with advanced automation systems that guarantee accurate cuts and shapes, minimizing waste and errors during the production process. Traditional construction methods often lead to discrepancies that can result in costly delays; however, with Omega's machinery, builders can achieve tight tolerances and uniformity with ease.

Moreover, the durability of the metal components produced by these machines cannot be overstated. Unlike timber framing, metal framing is less susceptible to pests, rot, and warping, ensuring longevity and reduced maintenance over time. This characteristic is particularly vital in regions prone to extreme weather conditions, where structural integrity is paramount.

omega estruc techo metalcon forming machine factories

Another notable benefit is the versatility offered by Metalcon forming machines. They are capable of producing a wide range of components, including studs, tracks, and other structural elements, all from the same machine. This multifunctionality not only saves space and investment in multiple machines but also streamlines the production process, allowing for quicker turnaround times on projects.

Sustainability and Environmental Impact

In today's construction industry, sustainability is a crucial consideration. Omega Estruc Techo stands at the forefront of this movement by developing metal forming machines that utilize recyclable materials. Steel is an inherently sustainable product, and using it in construction reduces the reliance on timber, which has a more significant environmental footprint. Furthermore, the efficiency of the manufacturing process minimizes energy consumption and waste, aligning with global efforts to create more sustainable building practices.

Conclusion

The Omega Estruc Techo Metalcon forming machines represent a pivotal advancement in the construction sector, marrying technology with practicality to meet modern demands. By providing builders with precision, durability, versatility, and sustainability, these machines are reshaping how structures are conceptualized and realized.

As the industry moves forward, embracing innovations like Omega's Metalcon forming machines will be crucial in addressing challenges posed by urbanization, environmental sustainability, and economic constraints. The future of construction is undoubtedly brighter with such revolutionary tools at our disposal. Thus, investing in technology like the Omega Estruc Techo Metalcon forming machines not only enhances productivity but also plays a vital role in shaping an efficient and sustainable built environment for generations to come.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025