omega estruc techo metalcon forming machine companies

An Overview of Omega Estruc Techo Metalcon Forming Machine Companies

In the dynamic landscape of the construction and manufacturing industries, Omega Estruc Techo Metalcon forming machine companies have emerged as pivotal players. These companies specialize in the production of advanced machinery designed for the efficient creation of metal components used in various structural applications. Utilizing cutting-edge technology, they provide solutions that meet the growing demands for strength, durability, and precision in construction materials.

The Metalcon Industry A Brief Insight

Metalcon, shorthand for metal construction, refers to a manufacturing sector focused on producing metal components for construction purposes. These components include panels, beams, and other structural elements that play a crucial role in building frameworks, roofing, and various architectural applications. As the construction industry continues to evolve, there is a steady demand for materials that can withstand environmental challenges, offer energy efficiency, and reduce structural weight without compromising strength.

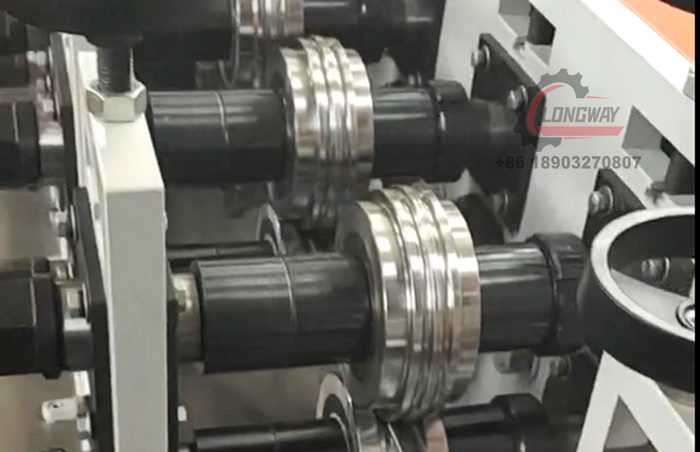

The Role of Forming Machines

In this context, forming machines are essential. They are designed to convert flat sheets of metal into pre-defined shapes and profiles. Omega Estruc Techo Metalcon forming machine companies offer a range of machines that utilize advanced forming techniques, such as roll forming and press braking, to produce high-quality metal profiles. These machines are pivotal in streamlining production processes, enhancing efficiency, and ensuring precision in dimensions, which is critical for construction applications.

Innovations in Technology

omega estruc techo metalcon forming machine companies

One of the hallmarks of Omega Estruc Techo Metalcon forming machine companies is their commitment to innovation. Through technological advancements, these companies are pushing the boundaries of what is possible in metal forming. For instance, the integration of computer numerical control (CNC) technology allows for improved accuracy and consistency in the production of metal components. Additionally, automated systems help reduce labor costs and minimize human error, which is a significant factor in maintaining production quality.

Sustainability in Metal Construction

Today, sustainability is a pressing concern in the construction industry. Omega Estruc Techo Metalcon forming machine companies are responding to this challenge by developing energy-efficient machines and processes that minimize waste. By using recyclable materials and optimizing production techniques, these companies are contributing to a more sustainable future in construction. Their efforts align with global trends toward reducing carbon footprints and promoting environmentally responsible practices in building projects.

Market Trends and Growth Opportunities

As urbanization continues to rise and infrastructure projects expand globally, the demand for metal components is expected to grow. Omega Estruc Techo Metalcon forming machine companies are well-positioned to capitalize on these trends. They can cater to diverse sectors, including residential, commercial, and industrial construction. Furthermore, the increasing preference for prefabricated construction techniques, which often require high-precision metal elements, opens up additional avenues for growth within the industry.

Conclusion

In conclusion, Omega Estruc Techo Metalcon forming machine companies are vital contributors to the evolving construction landscape. With their innovative technologies, commitment to sustainability, and the ability to adapt to market demands, they are shaping the future of metal construction. As these companies continue to develop advanced machinery that meets the stringent requirements of the modern construction industry, they are not only enhancing the efficiency of metal fabrication but also playing a significant role in creating resilient and sustainable built environments. The integration of their solutions will undoubtedly lead to a stronger, more efficient construction sector in the years to come.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025