new gutter machine

The Innovations and Advantages of the New Gutter Machine

In recent years, the construction and home improvement industries have seen significant advancements in technology, leading to the development of tools that enhance efficiency and precision. One of the most notable innovations is the new gutter machine. This sophisticated piece of equipment has revolutionized the way gutter systems are installed and maintained, providing a myriad of benefits to contractors and homeowners alike.

Gutters play a crucial role in protecting a building from water damage. They direct rainwater away from the foundation, preventing potential issues such as soil erosion, flooding, and mold growth. Traditionally, installing gutters required careful measurement, cutting, and fitting, often resulting in time-consuming work and discrepancies during installation. With the advent of the new gutter machine, these challenges are significantly mitigated.

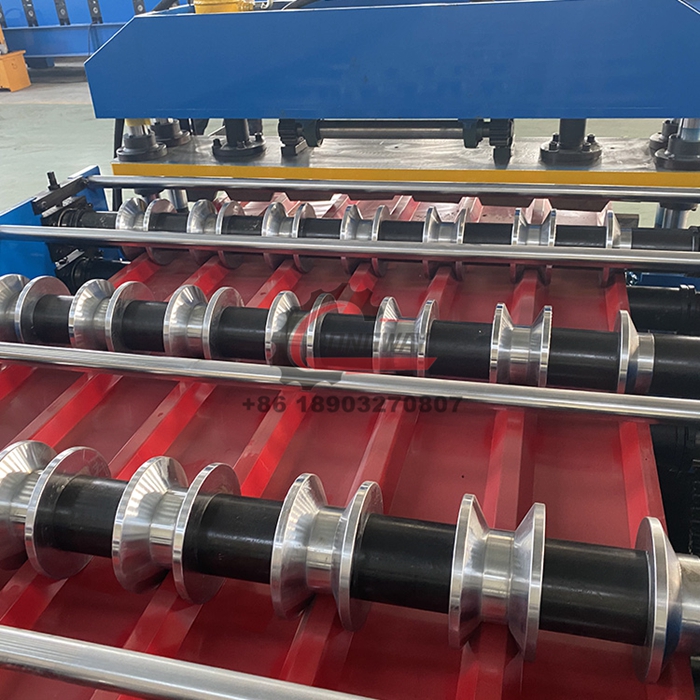

One of the most striking features of the new gutter machine is its automation. Many models now come equipped with advanced technology that allows for automated feeding and cutting of materials. This streamlines the manufacturing process, enabling users to produce custom gutters on-site. By eliminating the need to transport pre-fabricated gutter sections, contractors can save time and reduce labor costs. The machine can quickly produce seamless gutters, which are not only aesthetically pleasing but also enhance durability by reducing the risk of leaks.

Additionally, the new gutter machine offers versatility

. Most models can handle a variety of materials, including aluminum, copper, and galvanized steel. This adaptability allows contractors to cater to different client needs and preferences, providing a range of options for gutter systems. Furthermore, the machines are designed to accommodate various gutter styles and sizes, ensuring that any building, regardless of its design, can benefit from a reliable drainage system.new gutter machine

From a practical standpoint, the new gutter machine promotes efficiency. The speed at which gutters can be produced means that projects can be completed in a fraction of the time compared to traditional methods. This efficiency is particularly beneficial for contractors who are often under tight schedules and needing to maximize productivity. Reduced installation time also translates to lower labor costs, which can significantly enhance profit margins.

Moreover, the precision of the new gutter machine cannot be overlooked. Manual installation methods often rely on the skill of the contractor, which can lead to discrepancies in measurement and fit. In contrast, the advanced design and technology of the gutter machine ensure that each section is cut and formed with exceptional accuracy. This not only improves the overall quality of the installation but also reduces the likelihood of costly errors.

The benefits of incorporating a new gutter machine extend beyond mere time and cost savings. The efficiency and precision of these machines contribute to the longevity of the gutter system itself. Well-fitted gutters that are produced using automated technology are less prone to leaks and other issues, leading to a more effective water management system for homes and buildings.

In conclusion, the new gutter machine represents a significant leap forward in the realm of construction and building maintenance. Its ability to produce high-quality, custom gutters quickly and efficiently addresses many of the challenges faced by contractors and homeowners in the past. By embracing this innovative technology, the industry not only enhances productivity but also improves the overall integrity of gutter systems installed. As the technology continues to evolve, it is likely that the new gutter machine will become an indispensable tool for any contractor looking to stay competitive in the ever-evolving marketplace.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025