metal tile roof roll forming machine

The Rise of Metal Tile Roof Roll Forming Machines

In recent years, the construction industry has seen a significant shift towards the use of metal roofing, particularly tile-style metal roofs. This trend is being driven by the numerous advantages metal roofs offer, including durability, energy efficiency, and aesthetic appeal. To meet the growing demand for these roofing solutions, metal tile roof roll forming machines have become essential tools in manufacturing.

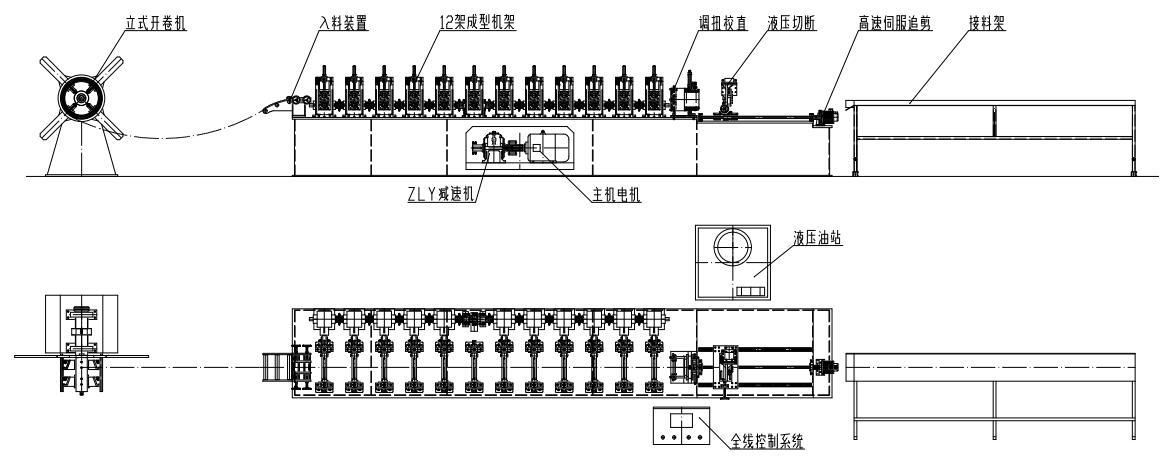

Metal tile roof roll forming machines are specialized equipment designed to create high-quality metal tiles for roofing applications. These machines work by feeding metal coils through a series of rollers that gradually shape the material into desired profiles. The process is highly efficient, allowing for continuous production and minimizing waste. With advancements in technology, modern roll forming machines are capable of producing complex tile designs that mimic traditional clay or concrete tiles, providing homeowners and builders with a variety of choices.

One of the primary advantages of using metal tile roof roll forming machines is the significant cost savings they offer. Once set up, these machines can produce large quantities of metal tiles in a short amount of time, reducing labor costs and increasing productivity. Moreover, the durability of metal roofing materials means less frequent replacements, resulting in long-term savings for property owners.

metal tile roof roll forming machine

Metal roofs are also known for their resistance to weather elements, making them an ideal choice for various climates. The roll forming process ensures that metal tiles are uniformly shaped and sized, contributing to better fit and finish during installation. This precision helps to prevent leaks and other issues often associated with improperly installed roofing materials.

Additionally, metal roofing is energy-efficient. The reflectivity of metal helps keep buildings cooler in the summer months, reducing the need for air conditioning and lowering energy bills. Many manufacturers now offer coatings that enhance reflectivity, further improving the energy efficiency of metal roofs. This aspect has become increasingly important for environmentally-conscious consumers looking to reduce their carbon footprint.

As the demand for metal roofing solutions continues to rise, the role of metal tile roof roll forming machines will only become more significant. These machines not only streamline the manufacturing process but also ensure that high-quality, aesthetically pleasing roofs are readily available. With continuous advancements in technology and an increasing emphasis on sustainability, the future of metal roofing looks bright, making it an excellent investment for both builders and homeowners.

In conclusion, the evolution of metal tile roof roll forming machines has transformed the roofing industry, allowing for efficient production of durable and attractive metal roofs. As technology continues to advance, we can expect even greater innovations that will further enhance the capabilities of these machines, shaping the future of construction and roofing.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025