Metal Stud Roll Forming Equipment for Efficient Construction Solutions and Customization

The Metal Stud Roll Forming Machine Revolutionizing Modern Construction

In the ever-evolving landscape of construction technology, the metal stud roll forming machine stands out as a crucial player in the efficient production of metal framing systems. This innovative equipment has transformed the way metal studs are manufactured, offering a blend of speed, precision, and versatility. As the construction industry continues to embrace advancements, understanding the role and advantages of metal stud roll forming machines becomes essential for architects, builders, and contractors alike.

What is a Metal Stud Roll Forming Machine?

A metal stud roll forming machine is a specialized piece of equipment used to create metal studs from steel or other metal sheets. The process involves feeding flat metal sheets into the machine, which then systematically shapes and rolls them into desired profiles through a series of rollers. The result is a continuous length of metal studs that can be cut to specific lengths as needed. This machinery can produce various profiles, including C-shaped and U-shaped studs, often used in drywall construction, framing, and structural support.

Benefits of Metal Stud Roll Forming Machines

1. Efficiency and Speed One of the most significant advantages of using a metal stud roll forming machine is the speed at which studs can be produced. Compared to traditional manufacturing methods, roll forming allows for rapid production, enabling builders to meet tight deadlines without compromising on quality. The machine can continuously operate with minimal downtime, thus streamlining the construction process.

2. Precision and Consistency The automated nature of roll forming machines ensures that each metal stud is produced with high accuracy. Adjustments can be made easily to cater to varying specifications, ensuring that all produced pieces meet exact tolerances. This precision reduces wastage and minimizes the need for costly rework, ultimately saving time and resources on the job site.

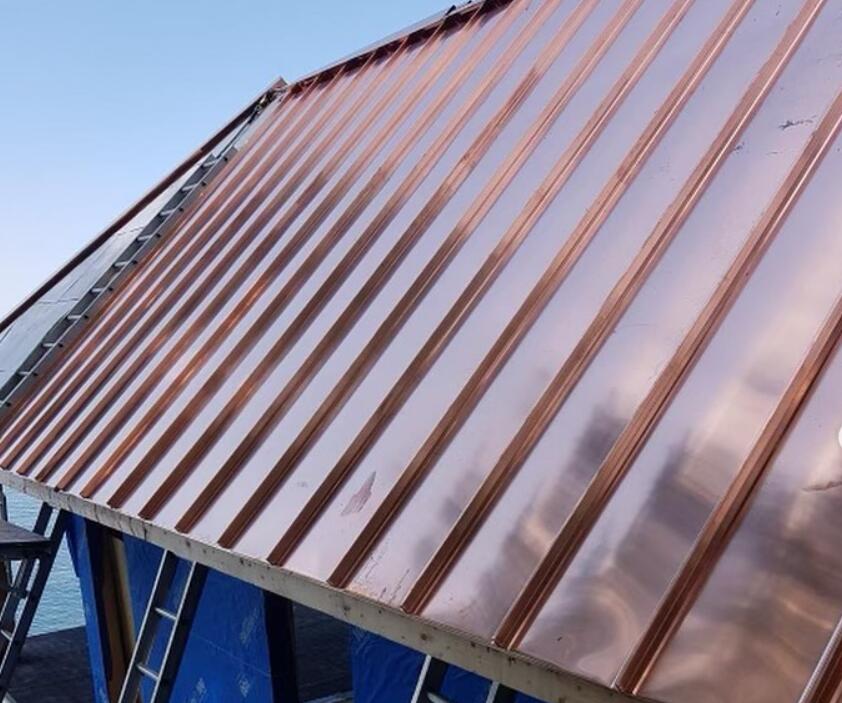

metal stud roll forming machine

3. Customization With advancements in technology, modern metal stud roll forming machines can be customized to produce a wide range of profiles and sizes. This flexibility is particularly advantageous for projects with specific design requirements. Builders can produce unique metal stud configurations that cater to individual project needs, enhancing creativity and functionality in designs.

4. Cost-Effectiveness While the initial investment in a metal stud roll forming machine may be substantial, the long-term savings it offers cannot be overlooked. The reduction in labor costs, improved material efficiency, and increased production rates contribute to a favorable return on investment. Additionally, the durability of metal studs produced using this method often results in lower maintenance costs over time.

5. Sustainability As sustainability becomes an increasingly important factor in construction, metal studs produced through roll forming processes adhere to environmentally friendly practices. Steel is a recyclable material, and the efficient use of resources during production minimizes waste. Furthermore, metal studs offer advantages in energy efficiency when integrated into building designs, contributing to overall sustainability goals.

Applications in Construction

Metal studs are widely used in various construction applications, particularly in commercial and residential buildings. They serve as the backbone for drywall installations, offering structural integrity and support. Additionally, metal studs are often found in partitions, ceilings, and other frameworks where strength and stability are vital. The versatility of metal studs allows them to be used in diverse environments, from high-rise buildings to simple residential projects.

Conclusion

The metal stud roll forming machine is a testament to the advancements in construction technology that promote efficiency, precision, and innovation. As the demand for metal framing systems continues to rise, these machines offer a solution that aligns with modern building practices. Investing in a metal stud roll forming machine not only enhances productivity but also positions builders and contractors at the forefront of the industry, ready to tackle the challenges of contemporary construction with confidence. As we look to the future, the integration of such technology will undoubtedly play a pivotal role in shaping the landscape of construction for years to come.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025