metal stud roll forming machine

Understanding Metal Stud Roll Forming Machines

In the construction industry, the demand for efficient and high-quality building materials is ever-growing. One such innovative solution that has gained prominence is the metal stud roll forming machine. This machine plays a crucial role in producing metal studs, which are essential components in drywall and framing construction.

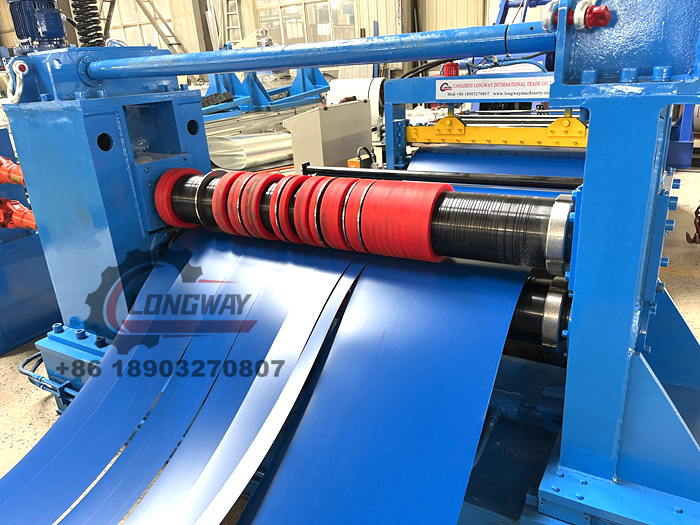

Metal stud roll forming machines are designed to convert flat metal sheets into various shapes and sizes of metal studs through a continuous process. The technology behind these machines involves feeding flat metal coils into a series of rollers that gradually shape the material into the desired profile. This method is not only efficient but also allows for significant customization based on specific project needs.

One of the key advantages of using metal studs over traditional wooden studs is their durability and resistance to fire, mold, and pests. Metal studs are made from galvanized steel or other metal alloys, providing structural integrity and longevity. Additionally, they do not warp or shrink, which makes them a reliable choice for both commercial and residential construction projects. With the increasing emphasis on safety and sustainability, metal studs are becoming the preferred option for builders and architects.

metal stud roll forming machine

The roll forming process itself is highly efficient. The machines can operate at high speeds, producing thousands of studs per hour, reducing labor costs and time on-site. Modern metal stud roll forming machines also incorporate advanced technologies such as computer numerical control (CNC) systems, which allow for precise measurements and cuts. This automation minimizes human errors and enhances overall production quality.

Another noteworthy aspect of metal stud roll forming machines is their versatility. These machines can produce various types of studs, including non-structural and structural options, catering to different applications. Whether it's for load-bearing walls, ceilings, or partitions, the flexibility of metal studs makes them suitable for a wide range of construction projects.

Furthermore, as the construction industry continues to evolve, metal stud roll forming machines are also adapting to new trends. Innovations in design and technology are leading to the development of more compact and efficient machines. These advancements not only enhance productivity but also reduce energy consumption, making them more environmentally friendly.

In conclusion, metal stud roll forming machines have revolutionized the way builders approach framing and drywall construction. With their efficiency, durability, and versatility, they have become indispensable tools in modern construction. As the industry continues to innovate, these machines will undoubtedly play a vital role in shaping the future of building materials and techniques.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025