Metal Stud Production Equipment Manufacturers for Efficient Construction Solutions

The Evolution and Impact of Metal Stud Making Machine Manufacturers

In the construction and interior design sectors, metal stud framing has gained considerable popularity due to its durability, lightweight properties, and resistance to environmental factors. As the demand for steel framing increases, so too does the need for efficient manufacturing processes. This is where metal stud making machines play a critical role, and the manufacturers producing these machines are pivotal in the evolution of modern construction practices.

The Importance of Metal Studs

Metal studs are essential components in constructing walls, ceilings, and other structural frameworks in both residential and commercial buildings. Unlike traditional wooden studs, metal studs offer several advantages they do not warp, twist, or shrink over time, and they are impervious to mold and pests. As construction practices evolve to favor sustainable materials and methods, steel framing has become a go-to option for builders looking to enhance the longevity and safety of their structures.

The Rise of Metal Stud Making Machines

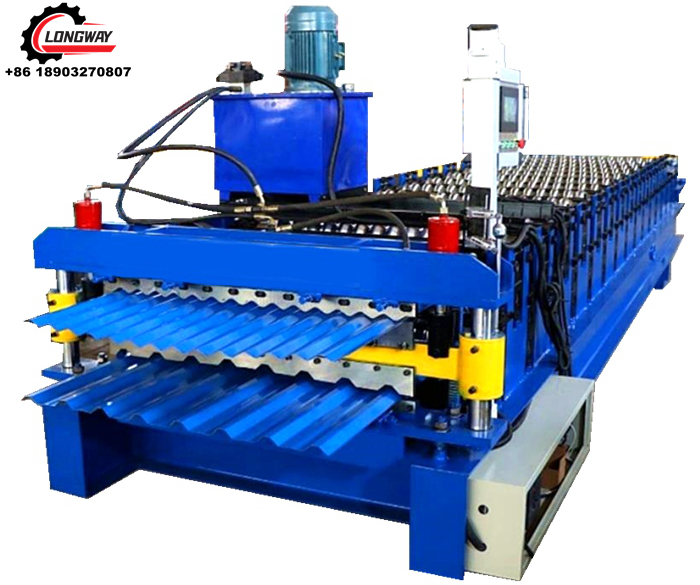

The surge in demand for metal studs has led to an increase in the number of manufacturing facilities equipped with advanced metal stud making machines. These machines are designed to process raw steel into precisely calibrated studs, ensuring high quality and consistency. Manufacturers generally focus on scalability, efficiency, and flexibility, allowing them to meet varying market demands. The technology behind these machines has evolved significantly, incorporating automation and precision engineering to enhance productivity and reduce waste.

Key Features of Metal Stud Making Machines

Modern metal stud making machines come with a variety of features that streamline the manufacturing process. Automated feeding systems allow for continuous production, while computer numerical control (CNC) systems improve precision in cutting and shaping metal. Additionally, many of these machines are designed to accommodate different gauges of steel, making them versatile for various applications. Some advanced models even offer real-time monitoring and diagnostics to ensure optimal performance, aiding manufacturers in reducing downtime and maintenance costs.

metal stud making machine manufacturers

Leading Manufacturers in the Industry

Several key players in the metal stud making machine manufacturing industry have set standards regarding quality and innovation

. Companies worldwide are constantly embracing technology, producing machines that are more efficient, user-friendly, and environmentally friendly. Some manufacturers integrate green technology, such as energy-efficient designs and the use of recycled materials in their machinery construction, reflecting a commitment to sustainability.Moreover, global competition pushes manufacturers to innovate continually, offering more advanced solutions such as hybrid systems that combine traditional processes with the latest technological advancements. These innovations not only improve efficiency but also enable manufacturers to provide customized solutions tailored to specific market needs.

Challenges and Future Prospects

Despite the advancements, metal stud making machine manufacturers face challenges such as fluctuating raw material prices and the necessity to adapt to rapid technological changes. The ongoing global shift towards digitalization and automation in manufacturing also demands substantial capital investment and skilled workforce development.

However, the future of metal stud making machines seems promising. The construction industry's shift towards sustainable building practices and materials could lead to increased demand for metal studs. Additionally, as emerging markets continue to industrialize, the need for modern manufacturing technologies will likely see substantial growth.

Conclusion

In conclusion, metal stud making machine manufacturers play a crucial role in shaping the future of the construction industry. Their ability to innovate and adapt to changing market dynamics influences the overall efficiency and sustainability of metal stud production. As we move forward, the integration of advanced technologies and sustainable practices will undoubtedly define the next era of metal framing, positioning manufacturers at the forefront of this evolutionary process. The symbiotic relationship between technology and industry will continue to push the boundaries of what is possible in construction, ushering in a new age of efficiency and innovation.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025