Metal Stud Manufacturing Equipment for Efficient Construction Solutions

The Rise of Metal Stud Making Machine Companies Transforming the Construction Industry

The construction industry has undergone a significant transformation over the past few decades, particularly with the introduction of more advanced materials and efficient manufacturing processes. Among these innovations, the rise of metal stud making machine companies has played a pivotal role in reshaping how construction projects are approached and executed. These machines offer a streamlined and cost-effective solution for producing metal studs, which are widely used in commercial and residential construction for framing and support structures.

Understanding Metal Studs and Their Importance

Metal studs are lightweight steel members that serve as an alternative to traditional wood framing. They are renowned for their durability, resistance to pests, and fire-retardant properties. As the demand for environmentally friendly building materials increases, metal studs have gained popularity due to their recyclability and lower carbon footprint. They are particularly advantageous in high-rise buildings, where their strength-to-weight ratio allows for taller and more robust structures without the added weight of traditional materials.

The importance of metal studs in modern construction cannot be overstated. They provide significant savings on labor costs and time due to their ease of installation. Metal studs are also less prone to warping or shrinking, ensuring that structures maintain their integrity over time. This shift toward metal framing has paved the way for companies specializing in metal stud making machines to emerge and flourish.

The Role of Metal Stud Making Machine Companies

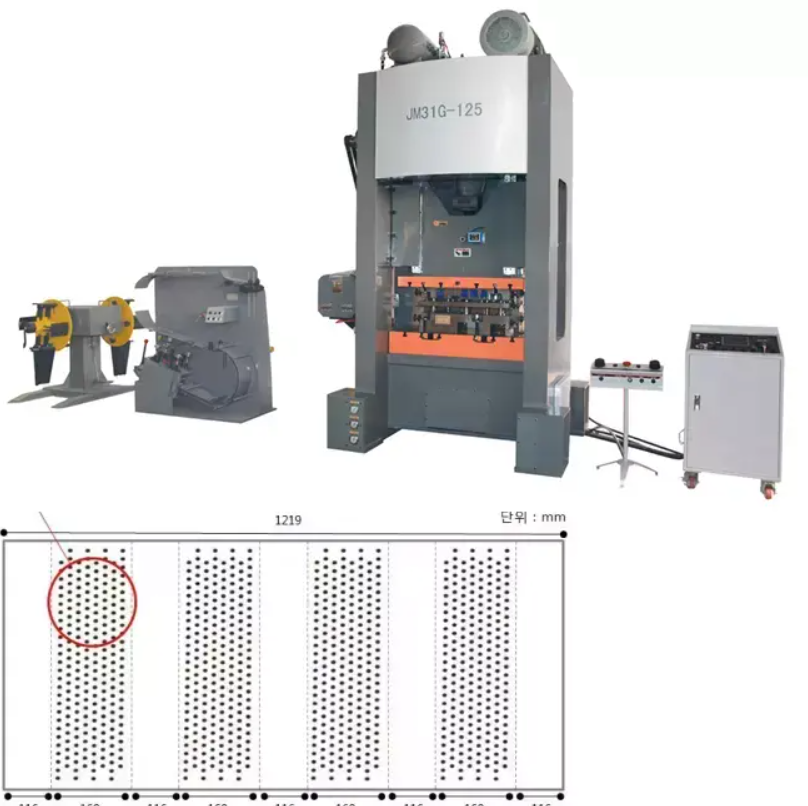

Metal stud making machine companies specialize in the design, manufacture, and sale of machinery that produces metal studs efficiently and accurately. These machines are engineered to operate at high speeds, allowing manufacturers to produce large quantities of metal studs while minimizing labor costs. The automated nature of these machines also reduces the risk of human error, ensuring that the end product meets stringent quality standards.

One of the key benefits of investing in a metal stud making machine is the ability to customize the product to meet specific project requirements. Many companies offer machines that can create studs of various sizes and profiles, catering to the diverse needs of the construction industry. This adaptability has made metal stud making machines essential tools for construction companies looking to maximize efficiency and minimize waste.

metal stud making machine company

Technological Advancements in Metal Stud Making Machines

The evolution of technology has introduced several advancements in metal stud making machines, enhancing their precision and capability. Modern machines are equipped with computer numerically controlled (CNC) technology, which allows for automated adjustments and programming based on project specifications. This level of automation not only increases production rates but also improves the precision of each metal stud produced.

Additionally, some machines now feature integration with software solutions that enable real-time monitoring of the production process. This capability allows manufacturers to track output, analyze performance metrics, and make data-driven decisions to optimize operations. The incorporation of artificial intelligence and machine learning into these systems is expected to further revolutionize the industry by predicting maintenance needs and identifying potential inefficiencies.

Sustainability and Eco-Friendliness

As global awareness of sustainability increases, metal stud making machine companies are also focusing on eco-friendly practices. Producing metal studs from recycled materials reduces waste and energy consumption, aligning with the values of modern construction firms that prioritize sustainable building practices. Moreover, the durability and longevity of metal studs contribute to reduced resource usage over the life cycle of a building, as fewer replacements and repairs are necessary.

Conclusion Future Prospects

In conclusion, metal stud making machine companies are at the forefront of a significant shift in the construction industry. As the demand for efficient, sustainable, and cost-effective building materials grows, these companies have carved out a crucial niche. With ongoing technological advancements and a commitment to sustainability, the future of metal stud making machines looks bright. As construction companies continue to embrace metal framing solutions, the role of these specialized manufacturers will only become more vital, leading to further innovations and efficiencies in the construction process. The metal stud making machine industry is indeed a cornerstone of modern construction, driving progress and shaping the buildings of tomorrow.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025