Metal Stud and Track Roll Forming Equipment Available for Purchase

Metal Stud and Track Roll Forming Machine for Sale A Comprehensive Overview

In the ever-evolving construction industry, the demand for lightweight yet durable building materials has surged. Among these materials, metal studs and tracks have gained significant popularity due to their strength, fire resistance, and ease of installation. With this rising demand comes the need for efficient manufacturing processes, leading to the popularity of metal stud and track roll forming machines. This article delves into the essential aspects of these machines, highlighting their importance, features, and the advantages they provide to manufacturers.

Understanding Metal Studs and Tracks

Metal studs and tracks are essential components used in modern construction, particularly in commercial buildings, residential homes, and interior partitions. Unlike traditional wooden studs, metal studs are made from galvanized steel, making them resistant to warping, fire, and pests. This resilience is a significant factor in why many builders prefer metal over wood for framing and structural applications.

The metal stud and track system typically involves horizontal tracks and vertical studs, which are connected to create a sturdy framework for walls, ceilings, and other structural elements. The roll forming process plays a crucial role in producing these components efficiently and cost-effectively.

The Role of Roll Forming Machines

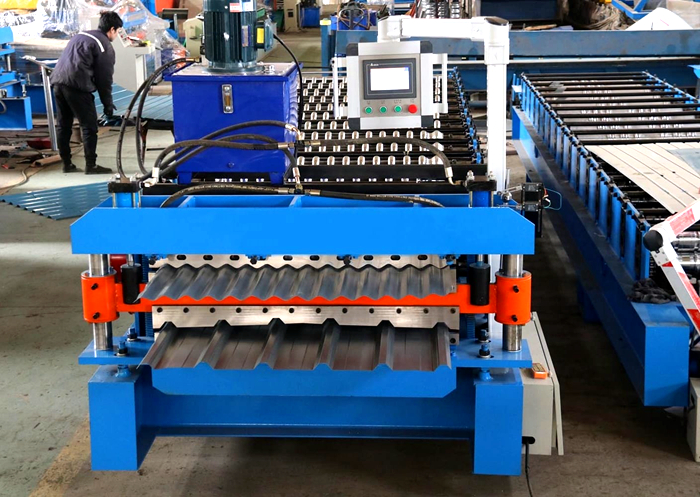

Roll forming is a continuous process where metal strips are fed through a series of rollers that gradually shape the material into the desired profile. This method allows for high precision and uniformity in the dimensions of the finished products. Metal stud and track roll forming machines are specifically designed to produce lightweight metal framing components that meet the strict standards of the construction industry.

These machines are equipped with advanced features, including automated controls, adjustable rolling stations, and high-speed operation capabilities. They can produce a variety of profiles to cater to different design requirements, making them an invaluable asset for manufacturers.

Key Features of Metal Stud and Track Roll Forming Machines

1. High Production Capacity Modern roll forming machines are engineered for speed and efficiency, allowing manufacturers to produce large volumes of metal studs and tracks in a short period.

metal stud and track roll forming machine for sale

2. Customizable Design Many machines offer flexibility in terms of design, enabling manufacturers to adjust the thickness, width, and profile of the metal studs and tracks according to specific project requirements.

3. Durability and Reliability Built with robust materials and advanced technology, these machines are designed to withstand the rigors of continuous operation, ensuring longevity and consistent performance.

4. User-Friendly Interface Most roll forming machines come with intuitive control panels, making it easy for operators to adjust settings and monitor production processes efficiently.

5. Cost-Effective Production By minimizing material waste and reducing labor costs, roll forming machines contribute significantly to lowering overall production costs.

Benefits of Investing in Metal Stud and Track Roll Forming Machines

Investing in a metal stud and track roll forming machine can provide numerous benefits for manufacturers

- Increased Profit Margins With the ability to produce high-quality products at a lower cost, manufacturers can improve their profit margins significantly. - Meeting Market Demand As the demand for metal framing systems continues to rise, having a dedicated roll forming machine enables manufacturers to meet customer needs swiftly and efficiently. - Enhanced Product Quality The precision of roll forming ensures that products are consistently high in quality, reducing the likelihood of defects and increasing customer satisfaction.

Conclusion

In conclusion, the metal stud and track roll forming machine is an essential tool for modern construction manufacturers. Its ability to produce durable, lightweight, and cost-effective metal framing components positions it as a valuable investment for those looking to thrive in the competitive construction market. As technology advances and the construction industry continues to evolve, these machines will play an increasingly pivotal role in shaping the future of building practices. Whether you are a seasoned manufacturer or just entering the market, consider exploring the opportunities presented by metal stud and track roll forming machines.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025