Metal Slitting Line Manufacturers and Their Impact on Industry Production Efficiency

Metal Slitting Line Factories An Overview

In the manufacturing industry, precision and efficiency are paramount, and one of the essential processes for shaping metal sheets is slitting. Metal slitting lines play a crucial role in this regard, serving as a cornerstone in various sectors such as automotive, aerospace, construction, and consumer goods. This article delves into the significance of metal slitting line factories, their operation, and the innovations driving their evolution.

What is a Metal Slitting Line?

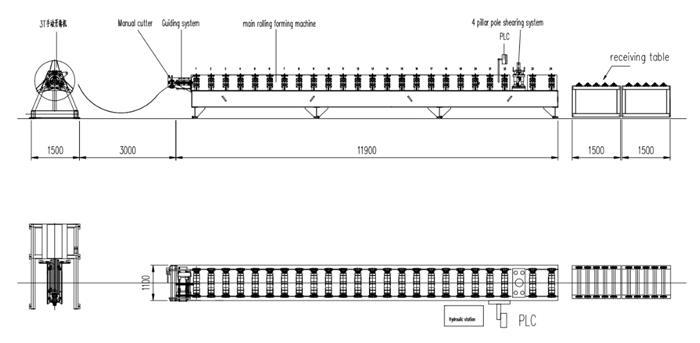

A metal slitting line is an assembly of equipment designed to cut large coils of metal into narrower strips with precise width specifications. The process typically involves uncoiling a metal roll, feeding it through slitter knives, and recoiling the resulting strips. The machinery in a slitting line includes elements such as uncoilers, shear blades, tension levelers, and recoilers, all working in tandem to ensure a streamlined workflow.

Importance of Metal Slitting Lines

The versatility of slitting lines allows manufacturers to produce a variety of metal products tailored to specific applications. Slitting is not merely a cutting process; it’s an essential part of the supply chain that dictates the quality and performance of the final products. For instance, in the automotive industry, the accuracy and integrity of slitted metal strips are critical for parts that must withstand high levels of stress and strain. Similarly, in construction, the right specifications can lead to safer, more reliable materials for building and infrastructure projects.

Major Components of Slitting Lines

1. Uncoiler This is the starting point of the slitting line, where metal coils are mounted and unwound for processing. The uncoiler must manage the weight and diameter of the coil while ensuring a consistent feed.

2. Slitting Head The core of the slitting line, the slitting head uses rotary knives to cut the metal into strips. The knives are adjustable, allowing manufacturers to customize strip widths according to client specifications.

metal slitting line factories

3. Levelers To ensure a smooth and uniform cut, the metal strips must be flat and free of defects. Levelers correct any warping or shape imperfections that may have occurred during the initial rolling of the metal.

4. Tension Control System This system maintains an even tension throughout the process, preventing variations in strip width and ensuring that the slitting process occurs smoothly.

5. Recoiler Once the metal strips are cut, they are wound back into coils using the recoiler. This final step helps in maintaining the product's integrity and prepares it for shipping.

Innovations in Metal Slitting Technology

As industries evolve, so do the technologies used in manufacturing processes. Recent advancements in automation, artificial intelligence, and material sciences have considerably improved the efficiency of metal slitting lines. Automated systems can now operate at higher speeds with reduced error rates, while AI algorithms analyze real-time data to optimize operational parameters dynamically.

Moreover, the integration of Industry 4.0 concepts has led to smart factories where metal slitting lines can communicate with other manufacturing units, enhancing overall productivity and reducing downtime. These innovations not only streamline production but also contribute to sustainable practices by minimizing waste and energy consumption.

The Future of Metal Slitting Line Factories

The demand for precision-engineered metal products continues to rise, driving the growth of slitting line factories worldwide. With the ongoing advancements in technology, these facilities are set to become more efficient, flexible, and capable of meeting the diverse requirements of modern manufacturing. As industries seek to adopt greener practices, slitting lines that utilize eco-friendly materials and processes will gain competitive advantages.

In conclusion, metal slitting line factories represent a vital segment of the manufacturing landscape. Through their advanced technologies, they enable the production of high-quality metal products essential for countless applications. As they continue to innovate and adapt, these factories will undoubtedly play a pivotal role in shaping the future of manufacturing across the globe.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025