Metal Siding Production Equipment for Sale from Leading Manufacturers Available Now

Metal Siding Machine for Sale A Comprehensive Overview for Manufacturers

In today’s construction and manufacturing industries, the demand for high-quality metal siding continues to soar. As builders and homeowners increasingly favor metal for its durability and aesthetic appeal, manufacturers are turning their attention to efficient production methods. One of the best investments a manufacturer can make is to acquire a metal siding machine, which enhances production capabilities while ensuring precision and quality. This article explores the importance of metal siding machines, their various types, features, and key considerations when looking to purchase one.

The Importance of Metal Siding Machines

Metal siding machines play a crucial role in producing siding materials that are not only visually appealing but also built to last. These machines enable manufacturers to create various styles and profiles to meet different market demands. With the right equipment, manufacturers can streamline their production processes, reduce waste, and improve efficiency—all while maintaining high-quality standards.

Types of Metal Siding Machines

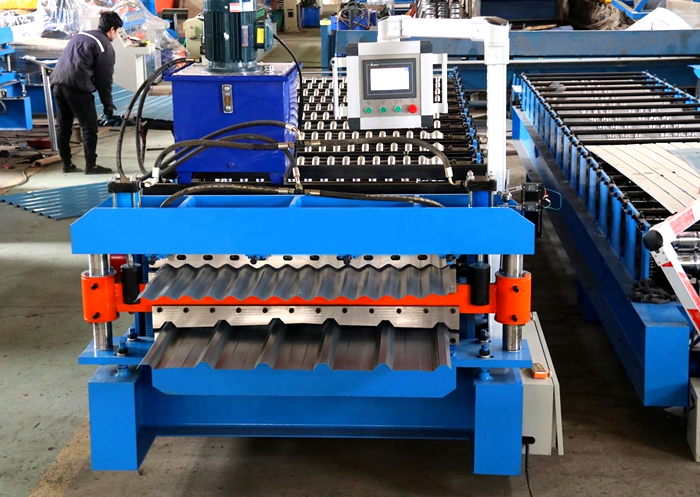

1. Roll Forming Machines One of the most common types of metal siding machines is the roll forming machine. This machine utilizes continuous rolls of metal and shapes them into desired profiles through a series of rollers. Roll forming machines are celebrated for their efficiency, producing long lengths of siding with minimal waste.

2. Panel Machines These machines are specifically designed to create flat panels that can be used for siding applications. They are essential for manufacturers looking to produce standardized panel sizes that align with industry specifications.

3. Cut-to-Length Machines For manufacturers needing precision in dimensions, cut-to-length machines are invaluable. They can cut metal sheets to the required length after the roll forming process, ensuring that each piece meets the specified measurements.

4. Slitting Machines Slitting machines are used to cut larger rolls of metal into narrower strips, which can then be further processed into siding materials. This adds flexibility to the production line and allows for customized orders.

metal siding machine for sale manufacturer

Key Features to Consider

When investing in a metal siding machine, several features should be considered to maximize return on investment

- Production Capacity Assess the machine’s ability to handle your production volume needs. It is vital to choose a machine that aligns with your anticipated demand to avoid bottlenecks in production.

- Material Compatibility Ensure the machine can work with various metal types (e.g., aluminum, steel) and thicknesses. Versatility in material handling enhances your manufacturing capabilities.

- Automation Features Modern metal siding machines often come equipped with automation technologies, such as computerized controls and monitoring systems. These features can significantly improve efficiency and consistency in production.

- Ease of Maintenance A machine that is easy to maintain will reduce downtime and operational costs. Look for models that boast simple maintenance protocols and readily available parts.

- Space Requirements Metal siding machines vary in size, so it’s essential to evaluate your available workspace before making a purchase. Ensure there is enough room not only for the machine itself but also for any feeding, cutting, and stacking operations.

Conclusion

Investing in a metal siding machine is a pivotal decision for manufacturers in the construction and façade industries. With the right machine, companies can boost production efficiency, enhance product quality, and respond better to market demands. By carefully considering the types of machines available, their features, and aligning them with specific operational needs, manufacturers can position themselves for sustainable growth in an ever-evolving market. Whether tapping into residential projects or large-scale commercial contracts, the right metal siding machine can be a game-changer.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025