Top Manufacturers of Metal Siding Forming Machines for Quality Construction Solutions

Exploring the World of Metal Siding Forming Machine Manufacturers

In recent years, the construction industry has witnessed a significant shift towards the use of metal materials for building exteriors. Metal siding not only provides durability and strength but also enhances the aesthetic appeal of any structure. As the demand for metal siding grows, so does the need for efficient manufacturing processes. This is where metal siding forming machine manufacturers come into play. These specialized producers create advanced machinery designed to efficiently shape, cut, and create metal siding panels.

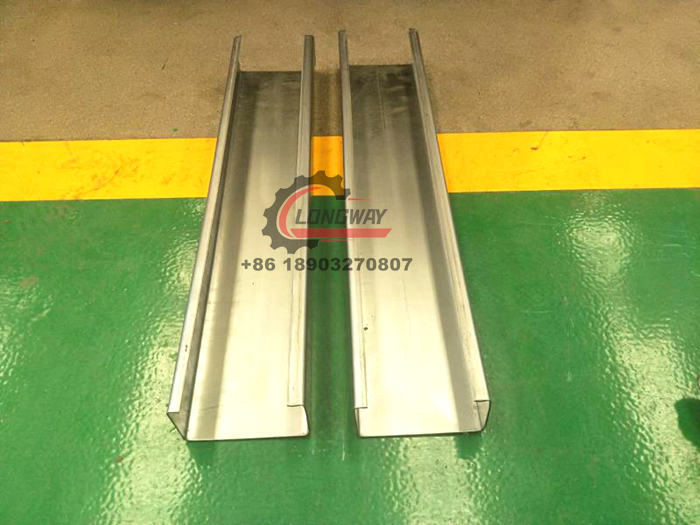

Metal siding forming machines are essential in producing a variety of siding profiles, which can be utilized in residential, commercial, and industrial buildings. They are capable of working with various steel substrates such as galvanized steel, aluminum, and even copper, allowing for a wide range of applications. These machines contribute to improved productivity, reduced labor costs, and increased precision, making them a vital component in the metal siding manufacturing industry.

The process of forming metal siding usually begins with coil metal. The coil is fed into the machine, where it undergoes a series of rolls and cuts to create the desired shape and thickness. This continuous process allows manufacturers to produce large volumes of siding efficiently. With advancements in technology, many manufacturers now offer automatic and computer-controlled systems that enhance precision and flexibility, enabling producers to easily switch between different panel profiles as per market demands.

One of the main advantages of using metal siding is its longevity. Metal can withstand harsh weather conditions, resist pests, and does not decay like wood. It is also non-combustible, making it a safer choice for many homeowners. Moreover, metal siding can be recycled, aligning with increasing environmental awareness and the push for sustainable building practices. As more builders and owners lean towards metal siding, the demand for more advanced forming machines is increasing.

metal siding forming machine manufacturers

The market for metal siding forming machines is diverse, with manufacturers spread across various regions. Some of the leading countries in this industry include the United States, China, and Germany, where innovation and advanced manufacturing techniques are prevalent. Companies in these regions focus on research and development to enhance machine performance, energy efficiency, and ease of use. Notable manufacturers are investing in automation and IoT integration, which allows for real-time monitoring and predictive maintenance of machines.

Choosing the right metal siding forming machine manufacturer is crucial for any business looking to enter or expand in the metal siding market. Factors to consider include the manufacturer's reputation, the technology used in their machines, after-sales support, and the quality of the components. A reliable manufacturer will provide adequate training for operators and ensure that spare parts are readily available, minimizing downtime during production.

Furthermore, attending industry trade shows and exhibitions can offer valuable insight into the latest trends and technologies in metal siding forming. Such events allow manufacturers to showcase their equipment, and buyers can assess various products before making purchasing decisions. Networking with industry professionals can also provide information on best practices and new business opportunities.

In conclusion, the need for high-quality metal siding is growing, and with it, the importance of metal siding forming machine manufacturers. Their role in supporting the construction and architecture industries cannot be overstated. By investing in advanced forming machines, businesses can enhance their efficiency and product offering, ultimately catering to the evolving needs of customers. Metal siding is not just a passing trend; it's a significant component of modern architecture, and with the right machinery, the future looks promising for manufacturers in this sector. Embracing innovation and sustainability will be key factors in maintaining a competitive edge in the metal siding market for years to come.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025