metal siding forming machine factories

The Evolution of Metal Siding Forming Machines A Look at Factories and Technology

In the construction and architectural industries, metal siding plays a crucial role in enhancing aesthetics, durability, and energy efficiency. With the increasing demand for high-quality metal siding, factories specializing in metal siding forming machines have emerged as vital cogs in the manufacturing process. These machines are designed to transform raw metal sheets into functional and appealing siding panels, catering to various commercial and residential needs. This article delves into the significance of these factories, the technology behind metal siding forming machines, and the future of metal siding production.

The Importance of Metal Siding

Metal siding is a popular choice for buildings due to its robustness and sustainability. It withstands extreme weather conditions, requires minimal maintenance, and is resistant to pests, decay, and fire. Additionally, metal siding can be recycled, making it an environmentally friendly building material. As architects and builders strive to design structures that are not only aesthetically pleasing but also energy-efficient, the role of metal siding becomes increasingly important.

The Function of Metal Siding Forming Machines

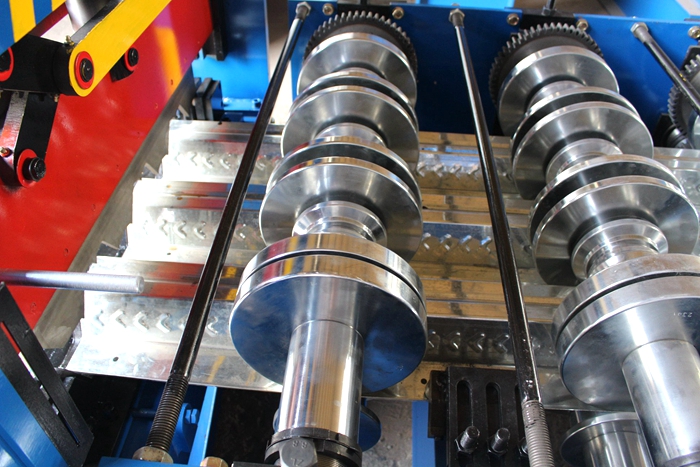

Metal siding forming machines are at the heart of siding production. These machines take large rolls of metal and process them through a series of rollers and forming stations to produce various siding profiles. The resulting panels can be designed for vertical or horizontal installation, in styles ranging from traditional to modern. The machines can also incorporate features such as insulation, color finishing, and texturing, enabling manufacturers to meet diverse customer requirements.

Key Technologies in Metal Siding Forming Machines

1. Roll Forming Technology This is the primary method used in the manufacturing of metal siding panels. Roll forming involves feeding a continuous strip of metal through a series of rollers that gradually reshape it into the desired profile. This technique allows for mass production with high precision and minimal waste.

2. Computer Numerical Control (CNC) Many modern metal siding forming machines are equipped with CNC technology, which enables precise control over the forming process. CNC systems automate the adjustment of machine components, improving efficiency and ensuring consistent quality across all produced panels.

metal siding forming machine factories

3. Punching and Cutting Systems Advanced forming machines can integrate punching and cutting systems that allow for customized designs. These systems can create holes for ventilation or decorative features, as well as cut the panels to desired lengths automatically, reducing the need for manual interventions.

4. Hydraulic Systems Hydraulic technology enhances the forming process by providing the necessary force to bend and shape the metal. This ensures that even thicker materials can be processed effectively, expanding the capabilities of metal siding production.

The Role of Factories in Metal Siding Production

Factories that specialize in the production of metal siding forming machines are instrumental in ensuring that manufacturers can meet the growing demand for high-quality siding. Many of these factories not only produce the machines but also provide training, maintenance, and support to operators, contributing to the overall success of siding manufacturers.

In addition, factories are continuously innovating, developing new technologies and techniques to improve machine efficiency and product quality. They often engage in research collaborations with engineering institutions and participate in trade shows to showcase advancements and connect with industry professionals.

The Future of Metal Siding Manufacturing

Looking ahead, the market for metal siding and its forming machines is expected to grow substantially. As the trend towards sustainable building materials continues to gain momentum, metal siding is well-positioned to remain a preferred choice. Moreover, advancements in technology such as increased automation, digitization, and the introduction of eco-friendly materials are likely to shape the future of metal siding production.

In conclusion, metal siding forming machine factories play a pivotal role in the construction industry. They not only provide the tools necessary for creating high-quality siding but also drive innovation and efficiency in the manufacturing process. As demand for metal siding grows, these factories will continue to evolve, ensuring they meet the diverse needs of their customers while contributing to a more sustainable future in construction.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025