Jan . 14, 2025 11:06

Back to list

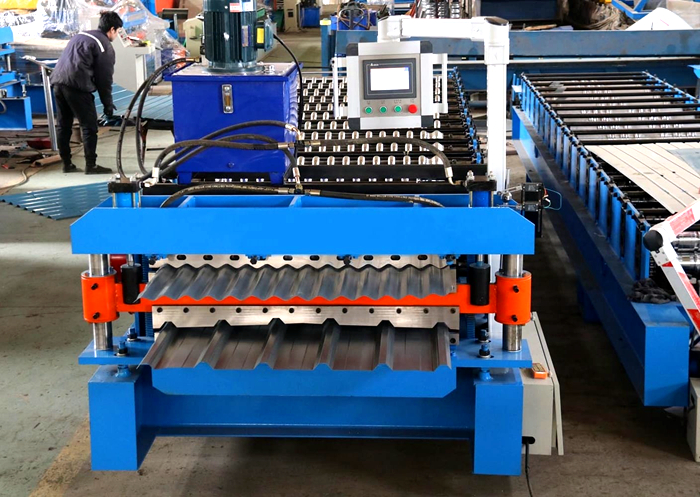

Metal sheet Perforados punching machine

In the ever-evolving landscape of industrial machinery, the simple slitting line stands as a cornerstone of efficiency and precision in metal processing. This essential equipment, used extensively in metalworking industries, is engineered to cut wide coils of metal into narrower strips, an operation that demands both precision and care. Understanding the intricacies of a simple slitting line not only enhances production efficiency but also underscores a commitment to quality and innovation in metal processing.

Establishing authority in the use of simple slitting lines involves staying abreast of the latest technological advancements. Industry leaders are now integrating digital solutions like IoT devices and AI-powered analytics to further enhance the functionality of slitting lines. These technologies provide detailed insights into the operational health of the machines and enable predictive maintenance, ensuring that the equipment runs smoothly without unexpected interruptions. By harnessing such cutting-edge technology, companies not only improve their operational efficiencies but also assert their authority as front-runners in the industrial domain. Trustworthiness in utilizing and managing simple slitting lines is fundamentally about guaranteeing product quality and ensuring worker safety. Ensuring that each slitting line adheres to strict safety standards and complies with industrial regulations is crucial. Regular training sessions for operators not only raise awareness about safety protocols but also build a culture of accountability and integrity. Companies that prioritize safety in operation essentially build trust with their stakeholders and establish long-term relationships that are vital for business growth. In essence, the simple slitting line is more than just a piece of machinery; it is a testament to the engineering prowess that powers modern industry. By emphasizing experience, expertise, authority, and trustworthiness, businesses can truly leverage the potential of simple slitting lines, achieving unparalleled efficiency and quality in metal processing. As the industry continues to innovate, those who adapt and evolve with these advancements will fortify their positions as leaders in the metal processing arena.

Establishing authority in the use of simple slitting lines involves staying abreast of the latest technological advancements. Industry leaders are now integrating digital solutions like IoT devices and AI-powered analytics to further enhance the functionality of slitting lines. These technologies provide detailed insights into the operational health of the machines and enable predictive maintenance, ensuring that the equipment runs smoothly without unexpected interruptions. By harnessing such cutting-edge technology, companies not only improve their operational efficiencies but also assert their authority as front-runners in the industrial domain. Trustworthiness in utilizing and managing simple slitting lines is fundamentally about guaranteeing product quality and ensuring worker safety. Ensuring that each slitting line adheres to strict safety standards and complies with industrial regulations is crucial. Regular training sessions for operators not only raise awareness about safety protocols but also build a culture of accountability and integrity. Companies that prioritize safety in operation essentially build trust with their stakeholders and establish long-term relationships that are vital for business growth. In essence, the simple slitting line is more than just a piece of machinery; it is a testament to the engineering prowess that powers modern industry. By emphasizing experience, expertise, authority, and trustworthiness, businesses can truly leverage the potential of simple slitting lines, achieving unparalleled efficiency and quality in metal processing. As the industry continues to innovate, those who adapt and evolve with these advancements will fortify their positions as leaders in the metal processing arena.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products