Metal Sheet Fabrication Equipment for Efficient Manufacturing and Precision Cutting

The Evolution of Metal Sheet Making Machines

In the modern industrial landscape, efficiency and precision are paramount, and metal sheet making machines play a crucial role in achieving these goals. These machines are designed to transform raw metal into usable sheets that find applications across numerous sectors, including automotive, aerospace, construction, and manufacturing. Understanding the significance of these machines and their evolution over time can shed light on the advancements in manufacturing technology.

Metal sheet making machines primarily serve the purpose of converting bulk metal into sheets of various thicknesses and sizes. Traditionally, this process involved manual labor and rudimentary tools, which were slow and often imprecise. The development of mechanical and hydraulic systems in the 19th century marked a significant turning point in the production of metal sheets. These innovations allowed for greater control over the shaping and sizing processes, paving the way for modern machinery.

Today’s metal sheet making machines are characterized by their automation, speed, and accuracy. Advanced technologies such as Computer Numerical Control (CNC) have revolutionized the manufacturing process. CNC machines utilize pre-programmed software to control the movement of tools, allowing for intricate designs and tight tolerances that were previously unattainable. This level of precision minimizes material waste and increases overall production efficiency.

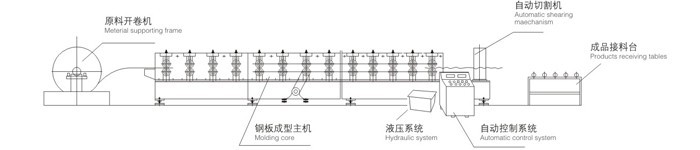

There are several types of machines involved in the metal sheet making process. Shearing machines, for instance, are used to cut large sheets into smaller, manageable sizes. Press brakes are employed to bend and form the metal sheets into various shapes, while roll forming machines create consistent profiles by bending continuous strips of metal. Each of these machines plays a unique role in the manufacturing workflow, ensuring that the final products meet specific design requirements.

metal sheet making machine

Moreover, advancements in technology have led to the integration of automation and robotics into metal sheet manufacturing lines. Automated systems can perform repetitive tasks with greater speed and consistency than human operators. This not only enhances productivity but also reduces labor costs and the risk of workplace injuries. Robotics in metal sheet making allows for precise handling of materials, making it possible to optimize operations further.

Environmental considerations have also influenced the evolution of metal sheet making machines. Manufacturers are now focused on producing equipment that minimizes energy consumption and reduces emissions. By integrating eco-friendly technologies and materials, these machines can contribute to more sustainable manufacturing practices. Innovations such as electric shears and energy-efficient hydraulic systems are now commonplace, reflecting the industry’s commitment to environmental responsibility.

Furthermore, the versatility of metal sheet making machines is evident in their ability to work with a variety of metals, including aluminum, steel, and copper. Each material presents unique challenges and requires specific settings and tool configurations. As technology progresses, machines are being designed to handle multiple materials with ease, enhancing their adaptability in diverse production environments.

In conclusion, metal sheet making machines have undergone significant transformations over the years, evolving from simple manual tools to advanced automated systems capable of producing high-quality sheets efficiently. The integration of modern technologies, coupled with a focus on sustainability, continues to shape the future of metal sheet manufacturing. As industries demand greater precision and efficiency, these machines will undoubtedly play an increasingly central role in meeting those needs, ensuring that they remain a vital component of the manufacturing landscape.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025