metal sheet making machine

The Metal Sheet Making Machine Revolutionizing Manufacturing Processes

In the world of manufacturing, precision and efficiency are paramount, and metal sheet making machines are at the forefront of this technological revolution. These machines play a crucial role in producing high-quality metal sheets that are utilized across various industries, including automotive, aerospace, construction, and electronics. This article explores the functionalities, benefits, and advancements in metal sheet making machines, emphasizing their significance in modern manufacturing.

Understanding Metal Sheet Making Machines

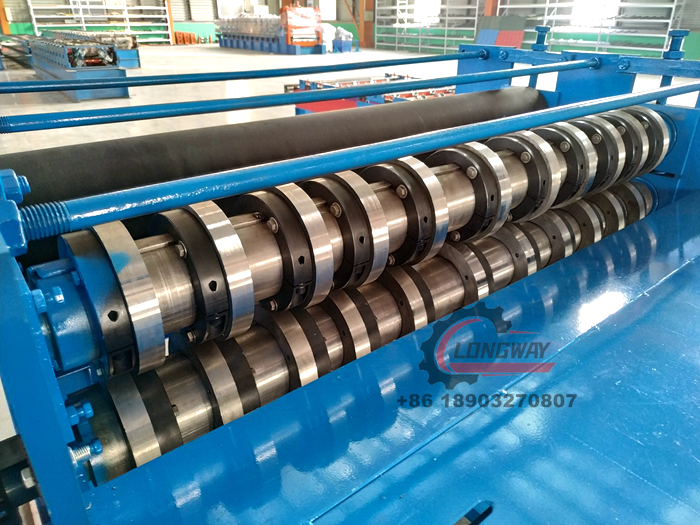

Metal sheet making machines are specialized equipment designed to process raw metal into flat sheets of varying thicknesses, lengths, and widths. Typically, these machines work with materials such as aluminum, steel, and copper, converting them into usable sheets through processes such as cutting, bending, rolling, and shearing. The precision of these operations ensures that the final product meets strict specifications and requirements.

The manufacturing process begins with metal coils, which are fed into the machine. Employing various techniques, the machine shapes these coils into sheets. For instance, roll forming is a common method where coils are passed through a series of rollers that gradually shape the metal into the desired sheet profile. Alternatively, stamping or shearing can be employed to achieve quicker production times and reduce waste.

Benefits of Metal Sheet Making Machines

One of the primary advantages of metal sheet making machines is their ability to enhance production efficiency. These machines are designed for high-speed operation, allowing manufacturers to produce large volumes of metal sheets in a short period. This increased output not only meets market demand but also significantly reduces labor costs and lead times.

metal sheet making machine

Moreover, modern metal sheet making machines are equipped with advanced technologies such as CNC (Computer Numerical Control) systems. CNC technology allows for precise control over machining operations, ensuring highly accurate dimensions and intricate designs. This level of precision is critical in industries like aerospace, where even the slightest deviation from specifications can lead to catastrophic failures.

In addition to efficiency and precision, these machines promote sustainability in manufacturing. Many metal sheet making processes are designed to minimize waste, recycling scrap metal back into production. This eco-friendly approach not only conserves valuable resources but also reduces operational costs associated with waste disposal.

Advancements in Technology

The landscape of metal sheet making machines continues to evolve with advancements in technology. Automation is making these machines smarter and more user-friendly. Today’s machines can be monitored and controlled remotely, enabling real-time adjustments and reducing downtime. This seamless integration of technology not only enhances productivity but also improves the accuracy of production.

Furthermore, innovations such as laser cutting and waterjet cutting have revolutionized the way metal sheets are processed. Laser cutting offers unparalleled precision and flexibility, allowing manufacturers to create intricate designs without the need for extensive tooling changes. Waterjet cutting, on the other hand, uses high-pressure water streams to cut through metal, resulting in clean edges and reducing the heat-affected zone.

Conclusion

Metal sheet making machines are indispensable tools that drive innovation and efficiency in the manufacturing sector. Their ability to produce high-quality metal sheets quickly and accurately makes them vital for industries that rely on precision-engineered components. With ongoing advancements in technology, these machines are set to become even more efficient, sustainable, and versatile. As manufacturers continue to adapt to the ever-changing demands of the global market, metal sheet making machines will undoubtedly play a central role in shaping the future of manufacturing. Embracing these innovations is essential for companies looking to enhance their competitiveness and operational effectiveness in an increasingly complex landscape.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025