metal roof tile making machine manufacturer

Metal Roof Tile Making Machine Manufacturer Revolutionizing the Roofing Industry

In today's construction landscape, the demand for durable, energy-efficient, and aesthetically pleasing roofing solutions has never been higher. One such solution is metal roofing, which has gained immense popularity due to its longevity, low maintenance requirements, and ability to withstand harsh weather conditions. At the heart of this booming market lies the metal roof tile making machine, a vital piece of equipment for manufacturers. In this article, we will explore the significance of these machines, the manufacturing process, and the key features that a leading manufacturer should offer.

The Importance of Metal Roof Tile Making Machines

Metal roof tile making machines play a crucial role in the production of high-quality metal tiles. These machines automate the entire process, resulting in a faster turnaround time and consistent product quality. With the construction industry increasingly shifting towards sustainable practices, metal roofing has emerged as a preferred choice due to its recyclability and energy efficiency. As a manufacturer, investing in advanced metal roof tile making machines not only enhances production capabilities but also ensures that the end product meets the stringent quality standards required by the market.

The Manufacturing Process

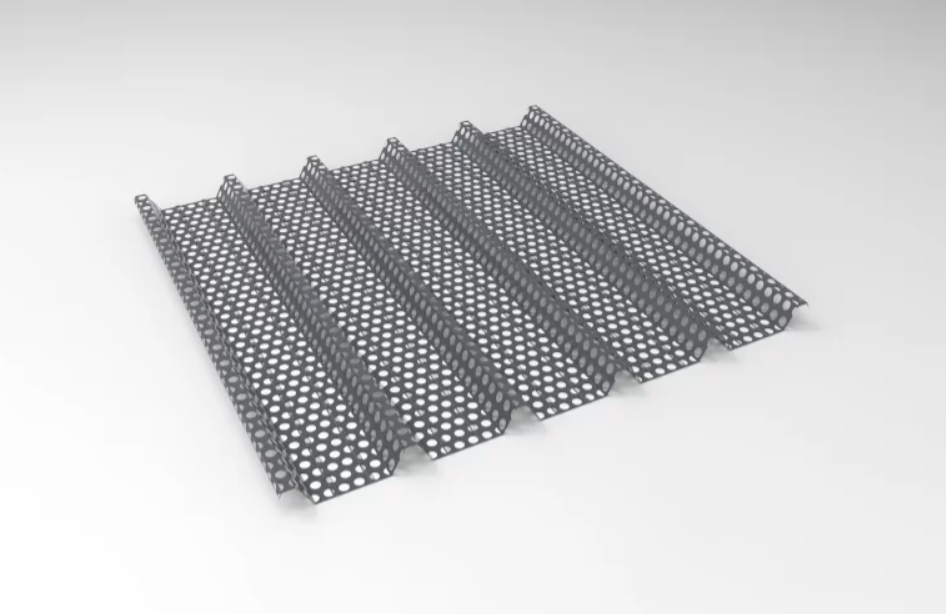

The manufacturing of metal roof tiles involves several steps, all of which are facilitated by specialized machinery. The process typically begins with the raw materials, which are usually sheets of galvanized steel or aluminum. These sheets are fed into the machine, where they undergo cutting and shaping processes. The metal is rolled and formed into various tile profiles, ensuring that manufacturers can offer a diverse range of options to their customers.

Once the tiles are shaped, they often go through a process of profiling and painting. Advanced metal roof tile making machines come equipped with pre-painting facilities, allowing manufacturers to apply a protective layer of paint to enhance the appearance and durability of the tiles. The final step involves quality checks and packaging, ensuring that the products reach the market in pristine condition.

Key Features of a Quality Machine Manufacturer

metal roof tile making machine manufacturer

When looking for a metal roof tile making machine manufacturer, there are several aspects to consider

1. Technology and Innovation A reputable manufacturer should utilize the latest technology in their machines, ensuring efficient operation, energy savings, and minimal waste. Machines equipped with advanced automation can significantly enhance productivity.

2. Customization Options Every market and region has different requirements. A manufacturer should provide customization options to meet varying needs, allowing for the production of a wide range of tile profiles, colors, and finishes.

3. Durability and Reliability The machines must be built to last, as roofing material production demands high durability. A reliable machine should require minimal maintenance while maintaining consistent performance over time.

4. Support and Service Exceptional after-sales support is crucial. A good manufacturer will offer training, installation assistance, and prompt maintenance service to ensure that operations run smoothly.

5. Sustainability As environmental concerns grow, partnering with a manufacturer that prioritizes sustainable practices can enhance a business's reputation. This includes using eco-friendly materials and ensuring the machine’s energy consumption is minimized.

Conclusion

In conclusion, metal roof tile making machines are indispensable for manufacturers looking to capitalize on the growing demand for metal roofing solutions. By investing in advanced technology and prioritizing quality, manufacturers can streamline their production process, reduce costs, and improve the overall quality of their products. As the construction industry continues to evolve, aligning with a quality machine manufacturer will be key to staying competitive and meeting the diverse needs of customers in an increasingly eco-conscious market. By embracing innovation and sustainable practices, manufacturers can ensure their place in the future of the roofing industry.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025