Manufacturers of Roof Sheet Forming Machines for Metal Construction Applications

Exploring the Role of Metal Roof Sheet Forming Machine Manufacturers in the Construction Industry

In the ever-evolving construction industry, the demand for durable, energy-efficient roofing solutions continues to surge, especially in the realm of metal roofing. This has led to an increasing reliance on advanced manufacturing technologies, particularly metal roof sheet forming machines. Manufacturers of these machines play a crucial role in shaping the future of building and construction, providing innovations that not only enhance efficiency but also ensure superior quality in metal roofing products.

The Significance of Metal Roofing

Metal roofing has gained significant popularity due to its myriad advantages, including longevity, resilience against harsh weather conditions, and aesthetic appeal. Compared to traditional roofing materials, metal roofing is less susceptible to damage, requires minimal maintenance, and can significantly improve energy efficiency by reflecting heat. As a result, the construction industry is witnessing a shift toward metal roofing solutions, which subsequently increases the need for high-quality metal roof sheet forming machines.

Understanding Metal Roof Sheet Forming Machines

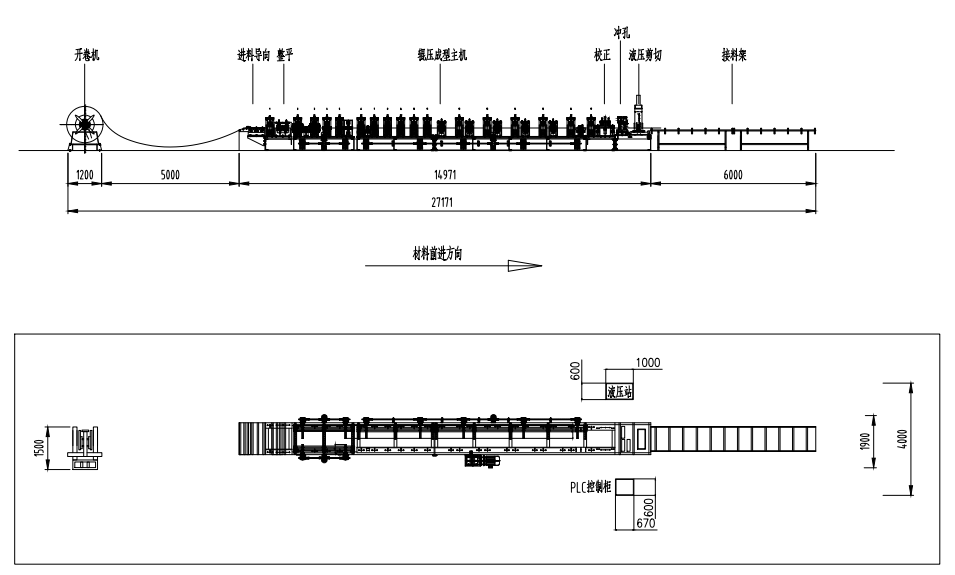

Metal roof sheet forming machines are specialized equipment designed to create roof panels from metal sheets. These machines utilize a series of rollers and cutting tools to transform flat metal sheets into various profiles suitable for roofing applications. The process includes metal shearing, roll forming, and cutting to length, allowing manufacturers to produce customized sheets that meet specific design and performance requirements.

The Role of Manufacturers

Manufacturers of metal roof sheet forming machines are at the forefront of providing technology that enhances production efficiency and product quality. They focus on several key aspects

metal roof sheet forming machine manufacturers

1. Innovation and Technology The best manufacturers continuously invest in research and development to incorporate state-of-the-art technology into their machines. Features such as computer numerical control (CNC), automated feeding systems, and advanced safety measures have become standard in the industry. These innovations not only streamline the production process but also improve accuracy, minimizing waste and reducing labor costs.

2. Customization Every project has unique requirements, and leading manufacturers offer customizable solutions tailored to specific needs. This includes the ability to produce various metal profiles, thicknesses, and finishes, allowing construction companies to have roofing solutions that fit their particular specifications.

3. Quality Assurance With the ever-increasing standards in construction quality, manufacturers also emphasize robust quality control processes. Every metal roof sheet forming machine undergoes rigorous testing and inspection before it reaches the market, ensuring that clients receive durable and reliable machines that fulfill their production demands.

4. Customer Support and Training Beyond providing machines, many manufacturers also offer extensive training and support services. They understand that the seamless operation of machinery is vital for production success; hence, they equip their clients with the knowledge and skills needed to operate and maintain the machines effectively.

5. Sustainability Practices As sustainability becomes a more pressing concern globally, manufacturers are also focusing on eco-friendly manufacturing practices. By producing energy-efficient machines and supporting the recycling of metal materials, they contribute to the overall reduction of the carbon footprint associated with the construction industry.

Conclusion

The role of metal roof sheet forming machine manufacturers is pivotal in driving innovations that cater to the growing demand for metal roofing solutions. As the construction industry continues to prioritize efficiency, sustainability, and quality, these manufacturers are well-positioned to meet the evolving needs of builders and contractors alike. Through their commitment to technology, customization, and customer satisfaction, they not only enhance the production processes but also contribute to the legacy of durable and reliable infrastructures in construction.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025