Metal Roof Sheet Production Machine for Efficient Roofing Solutions

The Advancements and Benefits of Metal Roof Sheet Forming Machines

In the realm of construction and manufacturing, the demand for durable, efficient, and aesthetically pleasing building materials has led to the rise of metal roofs. Among the pivotal innovations that cater to this demand is the metal roof sheet forming machine. This sophisticated equipment has revolutionized the way metal roofing materials are produced, offering a myriad of advantages to both manufacturers and end-users.

Understanding Metal Roof Sheet Forming Machines

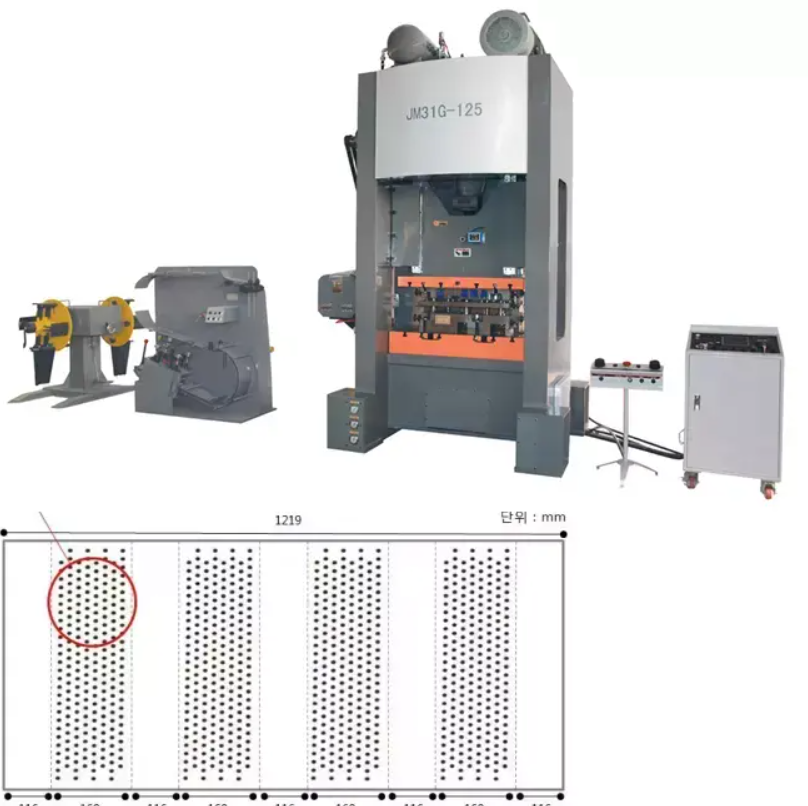

Metal roof sheet forming machines are specialized machines that convert metal coils into finished roof panels. The process typically involves feeding metal sheets into a roll-forming system, where they are shaped into various profiles, such as corrugated, tile, or standing seam roofs. These machines are designed to deliver precision and consistency, ensuring that each sheet meets stringent quality standards.

The machines operate by employing a continuous roll-forming technique. This method not only enhances efficiency but also minimizes waste, as the production process is streamlined to utilize as much of the metal coil as possible. Moreover, advancements in technology have led to the development of automated systems that enhance production speed and accuracy, resulting in higher output levels with reduced labor costs.

Advantages of Metal Roofing

Metal roofing has become increasingly popular in recent years due to its numerous benefits. Firstly, it boasts exceptional longevity. Metal roofs can endure harsh weather conditions, including heavy rain, snow, and high winds, often lasting 50 years or more with proper maintenance. This durability translates to lower long-term costs for homeowners and builders alike.

metal roof sheet forming machine

Secondly, metal roofs are lightweight, which reduces the load on a building's structure. This property allows for easier installation and can contribute to lower construction costs. Additionally, metal roofing materials are often made from recycled materials and can be fully recycled at the end of their lifespan, making them an environmentally friendly choice.

Energy efficiency is another significant advantage of metal roofing. Many metal roofs are coated with reflective finishes that can help reduce heat absorption, keeping buildings cooler in the summer months. This can lead to decreased energy costs for heating and cooling, making metal roofs an economically sound investment.

The Role of Metal Roof Sheet Forming Machines

The metal roof sheet forming machine plays a crucial role in facilitating the adoption of metal roofing. By producing high-quality sheets efficiently, manufacturers can meet the growing demand for metal roofs. Additionally, these machines can be customized to produce various profiles and thicknesses, providing versatility that caters to diverse architectural styles and customer preferences.

As the market for sustainable and efficient building materials continues to expand, the significance of metal roof sheet forming machines becomes even more pronounced. Innovations in the design of these machines, such as the incorporation of smart technology and enhanced automation, enable manufacturers to stay competitive while meeting the stringent demands of modern construction.

In conclusion, metal roof sheet forming machines represent a significant advancement in the construction industry, driving the popularity of metal roofing. With their ability to produce durable, lightweight, and energy-efficient roofing materials, these machines not only meet the demands of the market but also support sustainable building practices. As technology continues to evolve, it is likely that we will see even more improvements in metal roof sheet forming machines, further solidifying their role in the future of construction.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025