metal roof roll forming machine exporter

The Growing Demand for Metal Roof Roll Forming Machines A Comprehensive Overview

In recent years, the construction industry has experienced a significant shift towards the use of metal roofing systems. This trend is primarily driven by the numerous advantages that metal roofs offer, including durability, energy efficiency, and aesthetic appeal. As a result, the demand for metal roof roll forming machines has surged, positioning manufacturers and exporters in this niche market for extensive growth.

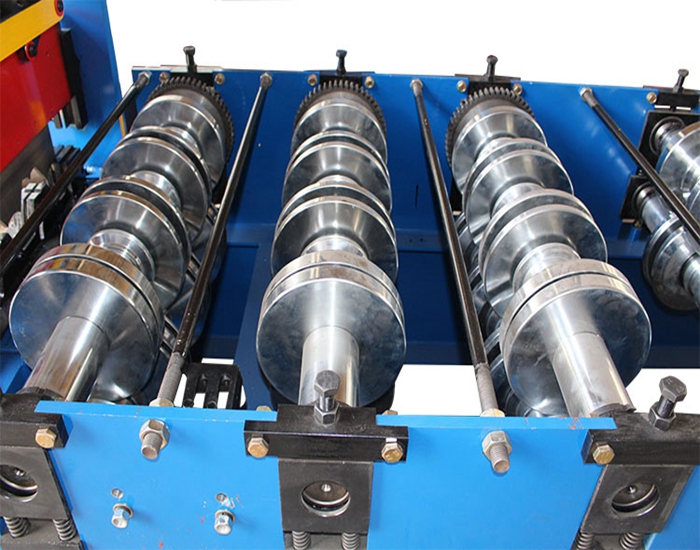

Metal roof roll forming machines are specialized equipment designed to produce metal roof sheets through a continuous process of bending and shaping metal strips. These machines operate by feeding metal coils into a series of rollers that progressively shape the material into the desired profile, which can then be cut to length according to specific requirements. The efficiency and precision of roll forming technology make it an invaluable asset for manufacturers in the roofing sector.

One of the primary benefits of utilizing metal roofs is their exceptional longevity. Unlike traditional roofing materials such as asphalt shingles, metal roofs can last up to 50 years or more with proper maintenance. This durability not only saves homeowners on replacement costs but also enhances the overall value of the property. Furthermore, metal roofing is resistant to harsh weather conditions, including strong winds and heavy rainfall, making it a reliable choice for regions with unpredictable climates.

Energy efficiency is another critical factor driving the adoption of metal roofing systems. Many metal roofs are treated with reflective coatings that help minimize heat absorption, reducing the need for air conditioning during hot months. This energy-saving characteristic has made them a popular choice among environmentally conscious homeowners and those looking to cut down on utility expenses. Additionally, metal roofing materials are often made from recycled sources, further contributing to sustainability in construction.

metal roof roll forming machine exporter

As the popularity of metal roofing escalates, so does the need for efficient and high-quality production. This is where metal roof roll forming machines play a pivotal role. Exporters of these machines are seeing increased demands not just domestically but internationally as well. Countries with burgeoning construction markets are eager to invest in advanced manufacturing technologies that can produce high-quality roofing components quickly and efficiently.

Advancements in technology have also led to the development of automated and computerized roll forming machines. These state-of-the-art systems allow for increased precision and flexibility, enabling manufacturers to produce custom designs and profiles tailored to specific customer needs. As a result, the market for metal roof roll forming machines continues to evolve, with a focus on innovation and enhanced productivity.

In the global marketplace, competition among metal roof roll forming machine manufacturers is fierce. Companies that wish to thrive must invest in research and development to stay ahead of industry trends and meet the changing demands of their customers. Moreover, ensuring high standards of quality and durability in machinery is crucial, as clients expect reliable performance and longevity from their investments.

Exporting metal roof roll forming machines requires not just an understanding of the machinery itself but also an awareness of international trade regulations, market conditions, and cultural nuances in different regions. Successful exporters are those who can effectively navigate these complexities while building strong relationships with clients across the globe.

In conclusion, the rise in demand for metal roofing is driving a corresponding need for high-quality metal roof roll forming machines. With their advantages in durability, energy efficiency, and aesthetic versatility, metal roofs are becoming a preferred choice in the construction industry. As the market continues to expand, exporters of roll forming machines must focus on innovation and quality to capitalize on this growth opportunity, ensuring they remain leaders in this dynamic field.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025