Metal Roof Ridge Cap Production Machine for Efficient Roll Forming Solutions

Metal Roof Ridge Cap Roll Forming Machine An Overview

In the modern construction industry, efficiency and durability are paramount, particularly when it comes to roofing systems. One of the key components of a robust roofing structure is the ridge cap, which serves as the essential finishing piece at the apex of a roof. To produce high-quality ridge caps, many manufacturers turn to advanced technology, such as the metal roof ridge cap roll forming machine.

What is a Metal Roof Ridge Cap Roll Forming Machine?

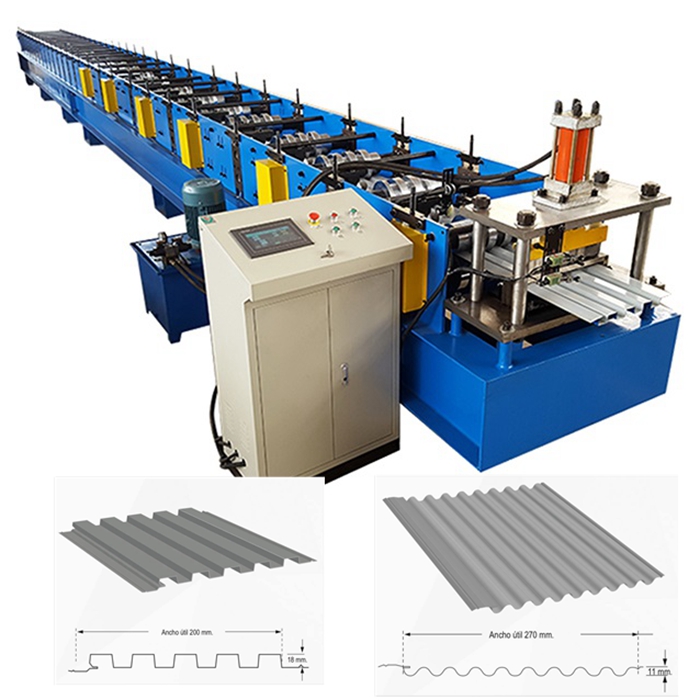

A metal roof ridge cap roll forming machine is a specialized piece of equipment designed to create ridge caps from metal sheets. This machine takes flat metal coils and processes them into various shapes required for roofing applications. The roll forming process involves feeding the metal through a series of rollers that progressively shape it into the desired contour, thus providing a consistent and precise end product.

Benefits of Using Roll Forming Machines

1. Precision and Consistency One of the primary advantages of using a roll forming machine is the high level of precision it offers. The machine ensures that each ridge cap produced is uniform in size and shape, which is crucial for effective installation. This consistency reduces the likelihood of errors during the construction process.

2. Cost-Effectiveness Although the initial investment in roll forming machinery can be significant, the long-term savings are considerable. The ability to produce materials on-site minimizes waste and reduces transportation costs. Additionally, the fast processing speed of these machines allows manufacturers to increase production rates, ultimately boosting profitability.

metal roof ridge cap roll forming machine

3. Versatility Metal roof ridge cap roll forming machines can accommodate various types of metals, including steel, aluminum, and copper, enabling manufacturers to cater to diverse customer needs. They also allow for customization in terms of size, shape, and profile, making them a flexible option for various roofing projects.

4. Durability and Strength The ridge caps produced by roll forming machines offer superior durability compared to traditional methods. The continuous rolling process enhances the strength of the metal, resulting in a robust product that can withstand harsh weather conditions, including heavy winds and snow loads.

The Process of Roll Forming Ridge Caps

The process of manufacturing ridge caps using a roll forming machine begins with loading metal coils into the machine. Once the coils are set, the machine unwinds the metal and passes it through a series of rollers. Each roller is precisely engineered to shape the metal incrementally. After forming, the ridge caps can be cut to length according to specifications.

Conclusion

In conclusion, the metal roof ridge cap roll forming machine is an invaluable asset for manufacturers in the roofing industry. By providing precision, cost-effectiveness, versatility, and durability, these machines help ensure the production of high-quality ridge caps that meet the demands of modern construction. As the industry continues to evolve, the adoption of such advanced technologies will remain crucial for staying competitive and delivering superior products to consumers. Whether for residential or commercial projects, investing in a metal roof ridge cap roll forming machine is a strategic decision that can lead to substantial long-term benefits.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025