metal roof machine price manufacturers

Understanding the Price of Metal Roof Machines and Leading Manufacturers

In recent years, the steel and metal roofing industry has experienced significant growth, driven by a surge in demand for durable, energy-efficient, and aesthetically pleasing roofing solutions. As a result, metal roof machines, essential for manufacturing metal roofing panels, have become increasingly sought after. This article will explore the various factors that influence the price of metal roof machines, as well as highlight some of the leading manufacturers in the market.

Factors Influencing the Price of Metal Roof Machines

The price of metal roof machines can vary significantly based on several critical factors

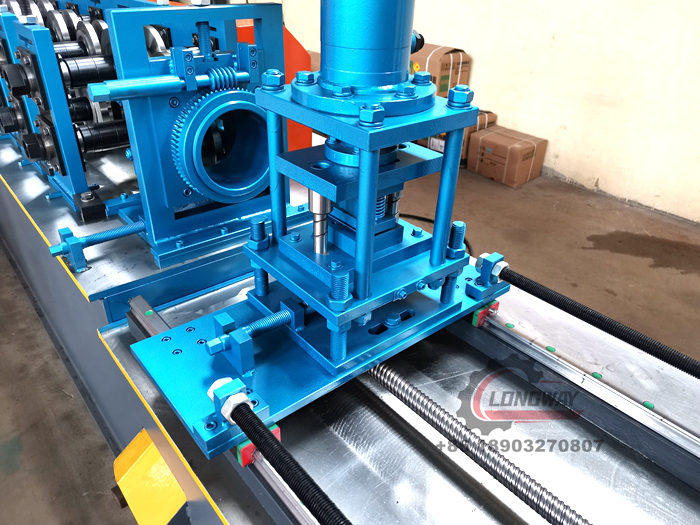

1. Type of Machine There are various types of metal roof machines, including roll-forming machines, shearing machines, and trimming machines. Each type serves a specific purpose, and the complexity of the machine can affect its price. For example, fully automated roll-forming machines tend to be more expensive than manual machines due to their advanced technology and bulk production capabilities.

2. Production Capacity The production capacity of a machine, measured in terms of the speed of production and the maximum size of panels it can handle, plays an essential role in pricing. Higher capacity machines that can produce larger volumes of roof panels quickly will generally cost more than lower capacity options.

3. Quality of Materials The quality of the materials used in the construction of the machine can greatly influence its price. Machines made from high-grade steel and components are generally more durable and effective, which can justify a higher cost. Additionally, machines that include features for improved efficiency and reduced waste may come at a premium.

4. Technology and Features Advanced technology integration, such as computer numerical control (CNC) systems and digital displays for monitoring production, contributes to higher costs. Machines equipped with features that enhance automation, precision, and ease of use are often preferred, which also impacts pricing.

5. Manufacturer Reputation The reputation and history of the manufacturer can affect pricing. Established suppliers with a proven track record of reliability and customer service often charge more for their machines due to their superior quality and after-sales support.

6. Geographic Location Prices can also vary by region due to shipping and transportation costs, import duties, and local market conditions. Buyers may find that sourcing equipment locally can lead to reduced transportation fees, while international purchases may offer better technology or lower base prices.

metal roof machine price manufacturers

Leading Manufacturers of Metal Roof Machines

Several key manufacturers have established themselves as leaders in the metal roof machine industry, known for their quality products and innovation. Here are a few notable names

1. Mekano Machinery Known for its high-quality roll-forming machines, Mekano Machinery offers a range of options tailored for various roofing applications. Their equipment is reputed for durability, efficiency, and excellent after-sales service.

2. Mack Equipment Mack Equipment specializes in customized metal roof machines, focusing on innovative solutions to meet specific customer needs. Their expertise in automation and production technology makes them a popular choice among contractors and businesses in the roofing sector.

3. C.P. Steel C.P. Steel has built a strong reputation for manufacturing robust and reliable metal roof machines. Their commitment to quality control and customer satisfaction has put them on the map as a preferred supplier in the industry.

4. Kingspan A leader in sustainable construction, Kingspan provides advanced manufacturing machinery for metal roofing. Their machines often incorporate energy-saving features and are designed with the environment in mind.

5. Rollforming Corporation This company offers a broad array of metal forming machines and is known for its innovative solutions that cater to both small-scale contractors and large manufacturing plants. Their dedication to research and development keeps them at the forefront of technology.

Conclusion

The price of metal roof machines is influenced by multiple factors, including the type, capacity, technology, and manufacturer. Understanding these elements can help businesses make informed purchasing decisions. Leading manufacturers like Mekano Machinery, Mack Equipment, C.P. Steel, Kingspan, and Rollforming Corporation continue to drive the industry forward, providing high-quality, efficient machines that meet the growing demand for metal roofing solutions. As the market evolves, staying abreast of technological advancements and pricing trends can ensure you invest wisely in metal roof machinery.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025