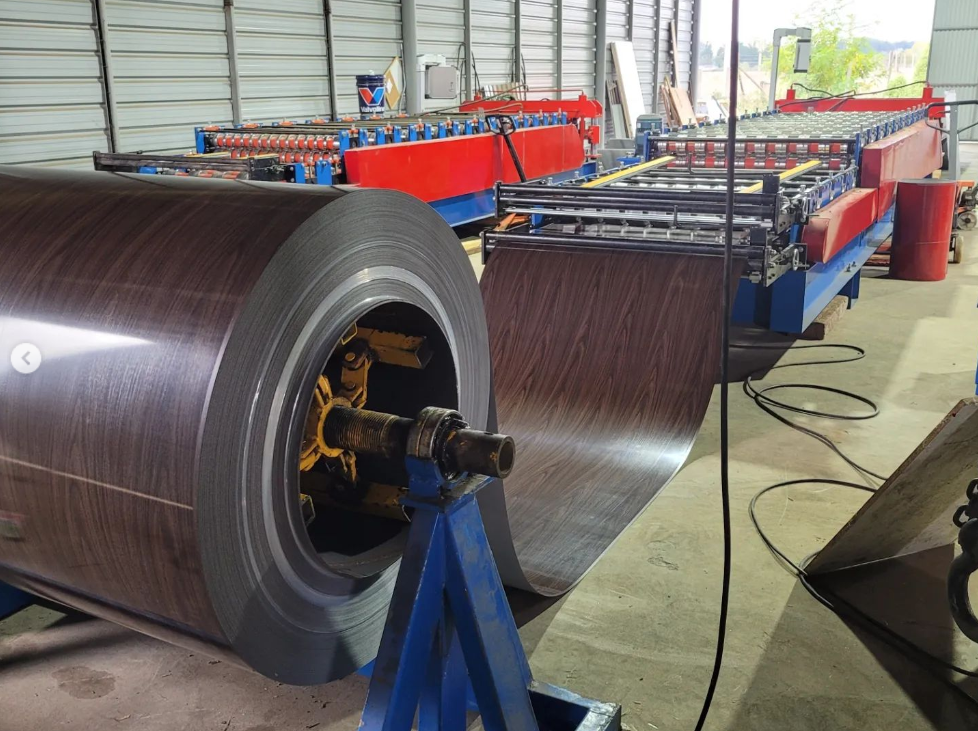

metal roofing tile roll forming machine factory

The Evolution and Importance of Metal Roofing Tile Roll Forming Machines

In recent years, the construction industry has increasingly turned to innovative solutions to meet the demands of modern building projects. One such advancement is the metal roofing tile roll forming machine, a vital piece of machinery that has revolutionized the way metal roofing tiles are produced. Understanding the significance of this technology is essential for those involved in construction and roofing materials manufacturing.

Metal roofing tiles have gained popularity due to their durability, energy efficiency, and aesthetic appeal. As more builders and homeowners opt for this roofing solution, the need for efficient production methods has skyrocketed. This is where metal roofing tile roll forming machines come into play. These machines are designed to produce metal roofing tiles directly from coils of metal sheets in a continuous and automated manner.

How Metal Roofing Tile Roll Forming Machines Work

At the core of a roll forming machine is a set of rollers that shape the metal sheets as they pass through. The process begins with a flat metal coil, which is fed into the machine. As the coil advances, it passes through a sequence of rollers that gradually bend and shape the metal into the desired profile of roofing tiles. This method not only ensures uniformity in size and design but also enhances production efficiency.

The machine can be customized to produce different styles and designs of roofing tiles, allowing manufacturers to meet various market demands. Common shapes include traditional tile profiles, standing seam panels, and other architectural designs. This versatility is one of the key advantages of using a roll forming machine, as it enables manufacturers to cater to a wider customer base.

Advantages of Metal Roofing Tile Roll Forming Machines

metal roofing tile roll forming machine factory

1. Efficiency One of the primary benefits of roll forming machines is their ability to produce large quantities of roofing tiles quickly. This efficiency is crucial for meeting project deadlines and managing costs in a highly competitive market.

2. Quality Control Automated forming processes minimize human error, resulting in higher quality and more consistent products. The precision of roll forming also ensures that tiles fit together seamlessly during installation, reducing the potential for leaks and other issues.

3. Cost-Effectiveness Though the initial investment in a roll forming machine can be substantial, the long-term savings on labor and material waste make it a financially sound decision for many manufacturers. Additionally, the durability of metal roofing tiles can lead to lower maintenance and replacement costs for homeowners.

4. Sustainability As environmental concerns continue to rise, the construction industry is increasingly focused on sustainability. Metal roofing tiles are often made from recycled materials, and their long lifespan contributes to reduced waste in landfills. Using a roll forming machine allows for efficient resource use, making the production process more sustainable.

Conclusion

In conclusion, the emergence of metal roofing tile roll forming machines has significantly impacted the roofing materials manufacturing industry. Their ability to produce high-quality, aesthetically pleasing, and durable roofing tiles efficiently meets the growing demand for metal roofing solutions. As technology continues to evolve, these machines will likely become even more advanced, further enhancing their capabilities and efficiency.

For manufacturers and builders alike, investing in metal roofing tile roll forming machines not only represents a forward-thinking approach to production but also aligns with the broader trends of sustainability and efficiency in construction. In an age where the need for reliable, durable, and eco-friendly building materials is paramount, these machines will continue to play a pivotal role in shaping the future of roofing solutions.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025