metal roofing tile roll forming machine company

The Significance of Metal Roofing Tile Roll Forming Machines in Modern Construction

In recent years, the construction industry has seen a significant shift towards more durable and sustainable building materials. Among these, metal roofing has gained immense popularity due to its longevity, energy efficiency, and aesthetic appeal. At the heart of this trend is the metal roofing tile roll forming machine, an essential tool for manufacturers looking to produce high-quality roofing materials.

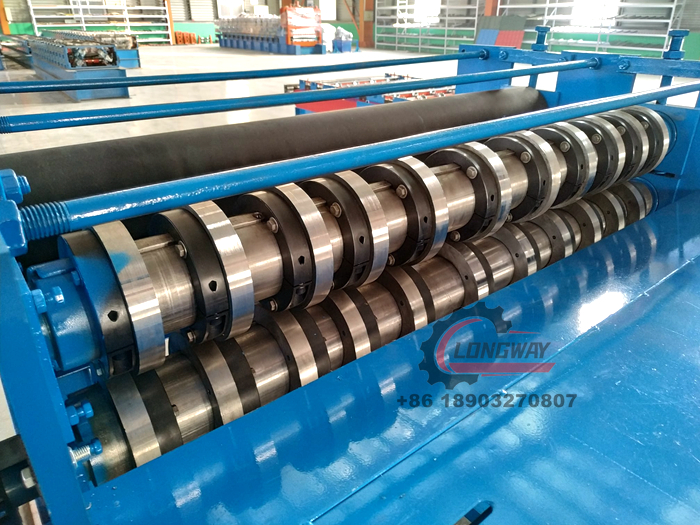

Metal roofing tile roll forming machines are designed to create seamless and precisely shaped tiles from metal sheets

. These machines operate through a series of rollers that gradually shape the raw metal into tiles of various profiles, including corrugated, standing seam, and tile-like designs. This versatility makes them invaluable to both large-scale manufacturers and small businesses aiming to cater to diverse consumer needs.One of the primary advantages of using metal roofing tile roll forming machines is their efficiency. With the ability to produce tiles at a rapid pace, these machines significantly reduce production times and labor costs. Advanced models are equipped with cutting-edge technology that ensures accuracy and consistency, minimizing waste and maximizing profitability. Furthermore, their automated features allow for easy adjustments to accommodate different tile designs, leading to greater flexibility in production.

metal roofing tile roll forming machine company

In addition to efficiency, the durability of metal roofing obtained from these machines cannot be overstated. Metal roofs are known for their resistance to extreme weather conditions, pests, and even fire. This resilience means that homeowners and builders can enjoy peace of mind when choosing metal roofing as a long-term investment. With proper installation and maintenance, metal roofs can last 50 years or more, making them an economically savvy choice.

Moreover, environmental concerns are increasingly influencing building material choices. Metal roofing is often made from recyclable materials, and at the end of its lifecycle, it can be repurposed rather than ending up in a landfill. By investing in metal roofing tile roll forming machines, manufacturers contribute to a more sustainable construction industry.

In conclusion, metal roofing tile roll forming machines play a crucial role in modern construction. They combine efficiency, versatility, and sustainability, making them essential for manufacturers aiming to meet the growing demand for high-quality metal roofing solutions. As the construction industry continues to evolve, these machines will undoubtedly remain at the forefront, helping to shape a durable and environmentally friendly future.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025