Top Manufacturers of Metal Roofing Tile Roll Forming Machines in the Industry

The Rise of Metal Roofing Tile Roll Forming Machine Companies

In today’s construction landscape, the demand for durable, aesthetically pleasing, and sustainable building materials has never been higher. Among these materials, metal roofing has emerged as a popular choice for many builders and homeowners alike. The metal roofing industry is booming, and at the heart of this success are companies specializing in metal roofing tile roll forming machines. These machines play a crucial role in manufacturing metal roofing tiles, providing efficiency, customization, and quality that meet modern architectural demands.

Understanding Metal Roofing Tile Roll Forming Machines

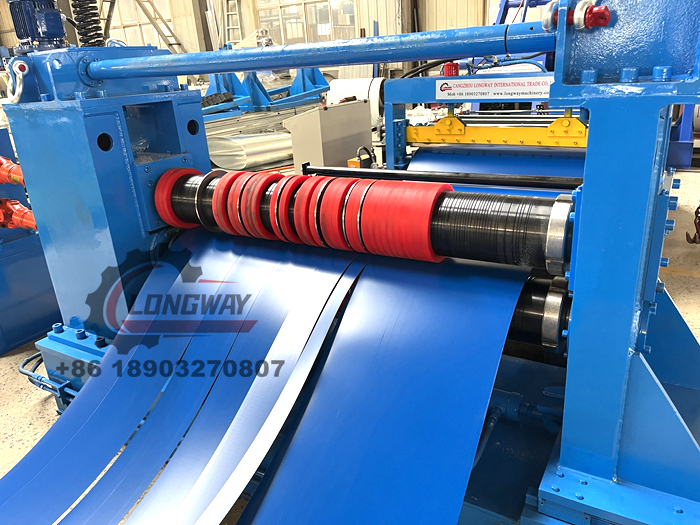

Metal roofing tile roll forming machines are advanced pieces of equipment designed to produce metal roofing tiles from metal coils through a continuous process. The process involves several stages, starting with the feeding of metal coils into the machine, which then shapes the material into the desired profile using a series of rollers. The result is high-quality metal roofing tiles that are lightweight, durable, and capable of withstanding various weather conditions.

These machines come equipped with advanced technology, allowing for automated operations that enhance production efficiency. Features such as computerized controls, programmable settings, and high-speed rolling capabilities make them essential in the competitive roofing market. Companies investing in roll forming machinery can produce a wide range of tile profiles to cater to different aesthetic preferences and specialized uses.

The Benefits of Metal Roofing

Metal roofing offers numerous advantages, contributing to its growing popularity in both residential and commercial sectors. One of the most significant benefits is its durability. Metal roofs can last 50 years or more with minimal maintenance compared to traditional roofing materials such as asphalt shingles, which typically need replacement every 15–20 years.

Additionally, metal roofs are highly resistant to extreme weather conditions, including hail, heavy rain, and high winds. They do not rot, crack, or warp, making them a reliable choice for many climates. Energy efficiency is another key benefit of metal roofing. Many metal roofing systems are reflective, helping to reduce cooling costs by keeping buildings cooler under the sun.

Furthermore, metal roofing is environmentally friendly. It is often made from recycled materials and is 100% recyclable at the end of its lifespan. This aligns with the increasing emphasis on sustainability in construction practices.

Leading Companies in the Metal Roofing Tile Roll Forming Machine Industry

metal roofing tile roll forming machine companies

Many companies specialize in manufacturing metal roofing tile roll forming machines, each contributing to the industry's growth and innovation. Some of the leading players include

1. Zhongtai Group Known for its advanced roll forming technology, Zhongtai Group manufactures a wide range of machines tailored for metal roofing production. Their commitment to quality and customer service has made them a preferred choice in many regions.

2. Cangzhou Zhiye This company is recognized for its robust design and high-performance roll forming machines. Their equipment is widely used in the metal roofing industry, offering versatility and efficiency.

3. Randall Manufacturing A prominent American manufacturer, Randall specializes in roll forming equipment for various applications, including metal roofing. With a focus on innovation, they continuously improve their machines to meet changing market demands.

4. KRM KRM is an international player providing a diverse range of roll forming solutions. Their machines are known for their durability and precision, ensuring high-quality outputs in metal roofing production.

Future Prospects of the Industry

As urbanization continues to rise and the need for sustainable building materials increases, the demand for metal roofing and roll forming machines is expected to grow. Companies operating in this sector are already innovating new technologies such as eco-friendly coating solutions and automatic cutting systems, further enhancing the efficiency of metal roofing production.

The global focus on green construction practices, government regulations promoting sustainable building materials, and the growing popularity of metal roofing for its energy efficiency will drive continued interest and investment in metal roofing tile roll forming machines.

Conclusion

The metal roofing industry is a dynamic and fast-growing sector that relies heavily on roll forming technology. Companies specializing in metal roofing tile roll forming machines are key to meeting the increasing demand for durable, sustainable roofing solutions. With their ability to produce high-quality roofing tiles and contribute to energy-efficient building practices, these companies play a vital role in shaping the future of construction. As innovation continues, the collaboration between machine manufacturers and roofing companies will pave the way for even more advancements in the industry.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025