Metal Roofing Sheet Roll Forming Equipment Manufacturers and Suppliers Guide

Exploring Metal Roofing Sheet Roll Forming Machine Factories

As the construction industry continues to grow, so does the demand for high-quality roofing materials. Among these materials, metal roofing sheets have become increasingly popular due to their durability, longevity, and aesthetic appeal. A crucial aspect of producing these roofing sheets lies in the technology and machinery employed in the manufacturing process, particularly in the form of roll forming machines. In this article, we explore the significance of metal roofing sheet roll forming machine factories and delve into the features, benefits, and considerations related to these machines.

The Role of Roll Forming

Roll forming is a continuous bending process in which a long strip of metal, usually coiled steel or aluminum, is fed through a series of rollers. These rollers gradually shape the metal into the desired profile or configuration. This method is particularly effective for producing metal roofing sheets that require a specific design, such as corrugated, standing seam, or tile patterns. The precision, efficiency, and repeated accuracy of the roll forming process make it an ideal choice for manufacturers looking to meet high production demands.

Key Features of Roll Forming Machines

Metal roofing sheet roll forming machines are equipped with various features that enhance their functionality and efficiency. Here are some of the key components found in these machines

1. Material Feeding System Automated rollers or guides that feed the metal coil into the machine for a smooth and continuous processing experience.

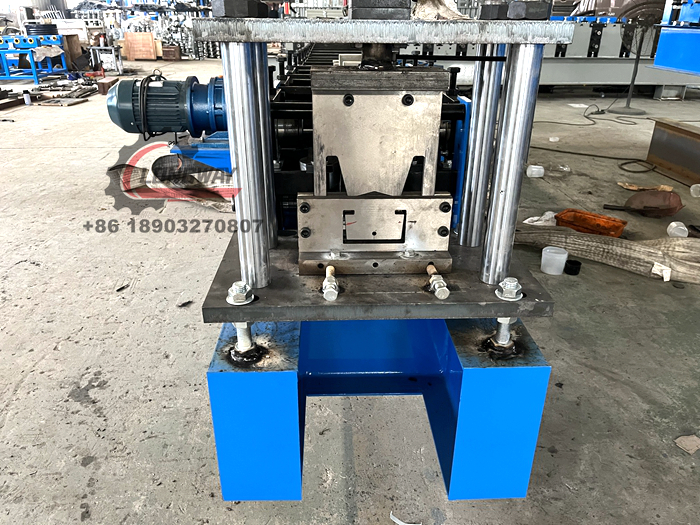

2. Roll Forming Station A series of rollers that shape the metal into the desired profile. These rollers are designed specifically for different roofing profiles and can be customized according to client specifications.

3. Cutting Mechanism An automated cutting unit is essential for trimming the roofing sheets to the required length. This can include flying shears or stop-cut systems that ensure precision cuts without disrupting the forming process.

4. Control Panel Modern roll forming machines come with advanced control systems that allow operators to monitor and adjust parameters such as speed, temperature, and pressure, ensuring optimal performance and quality.

5. Safety Features Given the heavy machinery involved, safety mechanisms such as emergency stops, shielding, and safety interlocks are critical to protect operators and maintain a safe working environment.

Benefits of Using Roll Forming Machines

Utilizing roll forming machines for metal roofing sheet production comes with several advantages

1. High Efficiency Roll forming can produce large volumes of roofing sheets in a relatively short period, making it cost-effective for manufacturers.

metal roofing sheet roll forming machine factories

2. Material Utilization The process minimizes waste, as metal strips are reshaped rather than cut, thus optimizing material usage.

3. Versatility Roll forming machines are adaptable to various materials and can produce different profiles by simply changing the roller sets.

4. Durability and Quality The precision of roll forming ensures that the roofing sheets are uniform in thickness and finish, leading to enhanced durability and performance.

5. Low Labor Costs Automated features reduce the requirement for manual labor, thereby lowering operational costs and increasing production rates.

Considerations When Choosing a Roll Forming Machine

When investing in a roll forming machine for metal roofing sheet production, several factors should be considered

1. Production Capacity Assessing the machine's output capabilities to meet your business's growth expectations is vital.

2. Customization Determine if the machine can accommodate specific roofing profiles that your market demands.

3. After-Sales Support Opt for manufacturers that provide reliable technical support and spare parts availability, ensuring smooth operations.

4. Initial Investment It’s essential to analyze the cost-benefit ratio, including the initial capital investment and the expected return over time.

5. Technology Upgrades Consider machines that allow for future upgrades, keeping you competitive in an evolving market.

Conclusion

Metal roofing sheet roll forming machine factories play a critical role in meeting the demands of the construction industry for durable and efficient roofing solutions. With advancements in technology, these machines continue to evolve, offering increased efficiency, versatility, and quality. For manufacturers looking to invest in this sector, understanding the key features and benefits of roll forming machines will pave the way for successful operations and customer satisfaction. Whether you are a seasoned player in the industry or a newcomer, the right roll forming machine can significantly enhance your production capabilities and contribute to your business growth.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025