Metal Roofing Sheet Roll Forming Equipment for Efficient Production and Quality Results

Exploring Metal Roofing Sheet Roll Forming Machines

In the construction and manufacturing industries, efficiency and precision are paramount. As the demand for durable, long-lasting structures continues to grow, metal roofing has emerged as a popular choice among builders, architects, and homeowners. Central to the production of metal roofing sheets is the metal roofing sheet roll forming machine, a technological innovation that streamlines the manufacturing process and ensures high-quality output.

What is a Metal Roofing Sheet Roll Forming Machine?

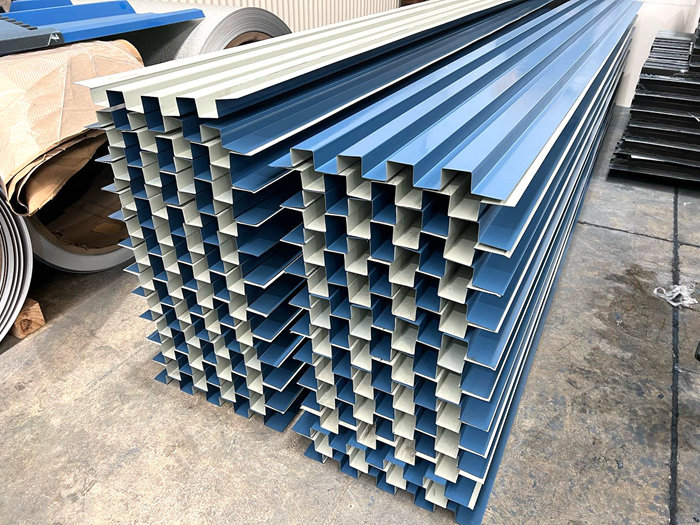

A metal roofing sheet roll forming machine is a piece of equipment designed to create metal roofing sheets from flat metal coils. The machine utilizes a series of rollers to progressively shape the metal into the desired profile, which can vary from classic corrugated patterns to more modern designs. This seamless process transforms raw materials into finished products efficiently, allowing for large-scale production that meets market demand.

Key Components and Operation

The operation of a metal roofing sheet roll forming machine involves several key components

1. Uncoiler This unit holds and feeds the metal coils into the machine. It ensures that the coil is properly aligned and tensioned for optimal forming.

2. Roll Forming Stations These are a series of rollers that shape the metal as it passes through. Each station accomplishes a specific step in the forming process, gradually achieving the final profile.

3. Cutting Mechanism After the metal has been formed, it needs to be cut to the desired length. The cutting mechanism can be either mechanical or hydraulic, depending on the design of the machine.

4. Control System Modern roll forming machines come equipped with advanced control systems, including programmable logic controllers (PLCs). These systems allow operators to adjust speed, thickness, and other parameters to ensure consistent quality.

5. Stacking Device Once the sheets are cut, they are stacked for easy handling. This component may also pack the sheets for shipment.

Advantages of Using Roll Forming Machines

metal roofing sheet roll forming machine

The use of metal roofing sheet roll forming machines offers numerous advantages

- Efficiency Roll forming is a continuous process, meaning it can produce a high volume of sheets in a short timeframe. This helps manufacturers scale their operations to meet rising demand.

- Cost-Effectiveness Automated systems reduce labor costs and minimize material waste, making the production process more economical.

- Versatility These machines can produce a variety of profiles and sizes, accommodating different design needs. Customization options allow for unique roofing solutions.

- Precision With computer-controlled systems, manufacturers can achieve high levels of precision, ensuring that every sheet meets specific tolerances and quality standards.

- Durability Metal roofs are known for their longevity and resistance to environmental factors such as corrosion, making them a wise investment for property owners.

Market Trends

The global market for metal roofing materials is expected to continue its upward trajectory, fueled by increased construction activities, especially in emerging economies. Metal roofing sheets are favored for their aesthetic appeal, energy efficiency, and sustainability. As builders and homeowners seek eco-friendly options, metal roofing emerges as a clear choice due to its recyclability and energy-efficient properties.

As technology continues to evolve, manufacturers of roll forming machines are also innovating. Advances in automation, artificial intelligence, and materials science are set to improve production processes further, enhancing the efficiency and sustainability of roll forming machines. Additionally, the rise of smart building technologies is likely to influence the design and functionality of roofing materials, pushing manufacturers to adapt.

Conclusion

In conclusion, metal roofing sheet roll forming machines play a crucial role in the evolution of the construction industry. They combine efficiency, precision, and versatility, making them indispensable for producing high-quality metal roofing solutions. As the demand for metal roofing continues to rise, the importance of these machines will only increase, paving the way for innovative manufacturing practices that align with sustainability and efficiency goals. Whether for residential, commercial, or industrial applications, investing in a metal roofing sheet roll forming machine presents a valuable opportunity for manufacturers looking to thrive in a competitive market.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025