Metal Roofing Sheet Production Equipment Manufacturing Facilities

Exploring the World of Metal Roofing Sheet Making Machine Factories

In recent years, the construction industry has witnessed a significant shift toward the use of metal roofing materials, owing to their durability, energy efficiency, and aesthetic appeal. At the heart of this industrial transition is the metal roofing sheet making machine, a crucial piece of equipment that facilitates the production of high-quality metal roofing sheets. This article delves into the intricacies of metal roofing sheet making machine factories, highlighting their importance, manufacturing processes, and the technological advancements shaping the industry.

The Significance of Metal Roofing

Metal roofing has become increasingly popular due to its numerous advantages over traditional roofing materials such as asphalt shingles or tiles. Metal roofs are known for their longevity, often lasting 40-70 years, which significantly reduces the frequency and cost of replacement. They also provide excellent insulation, which can help reduce heating and cooling costs. Moreover, metal roofs are resistant to extreme weather conditions and are environmentally friendly, as many metal roofing materials are recyclable.

Overview of Metal Roofing Sheet Making Machines

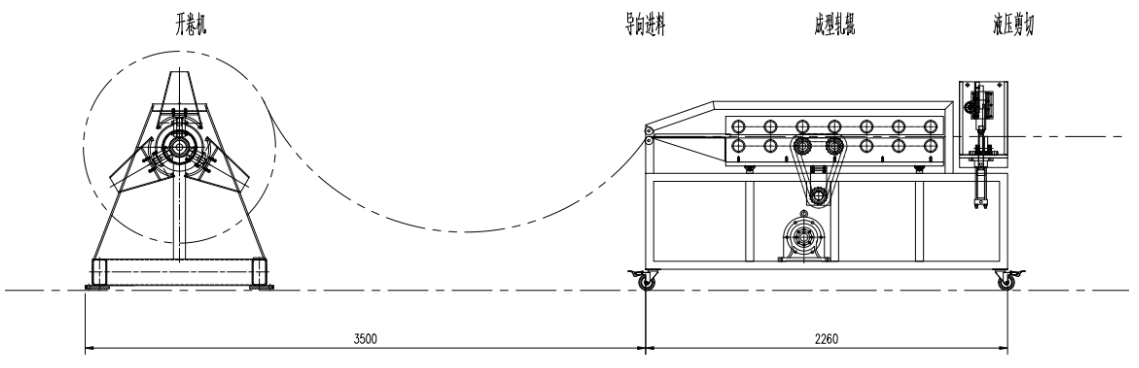

Metal roofing sheet making machines are designed to produce sheets of various profiles and thicknesses using metals like steel, aluminum, or copper. These machines utilize advanced techniques to ensure precision and efficiency, producing materials that meet the rigorous standards of the construction industry. Factories producing these machines play a crucial role in supplying manufacturers with the necessary tools to create high-quality roofing products.

Manufacturing Processes in Factories

Metal roofing sheet making machine factories typically employ a multi-step manufacturing process

1. Design and Engineering This initial stage involves designing the machine based on specific requirements. Engineers consider various factors, such as the type of metal to be used, the desired sheet profile, and production capacity. Advanced software tools are often employed to create precise designs.

metal roofing sheet making machine factories

2. Fabrication Once the designs are finalized, the manufacturing process begins. Factories use high-quality raw materials to construct the machine's frame, rollers, and components. Precision machining is essential during this stage, as it ensures that all parts fit together perfectly, resulting in a reliable and efficient machine.

3. Assembly After fabrication, the various components of the machine are assembled. This involves integrating the rollers, hydraulic systems, and control panels to create a functional unit. Skilled technicians oversee the assembly process to ensure quality and precision.

4. Testing Before the machines are shipped to customers, they undergo rigorous testing. This includes running the machines through their paces to ensure they operate effectively and produce sheets that meet the required specifications. Any necessary adjustments are made during this stage to fine-tune the machines.

5. Quality Control Quality assurance is a critical aspect of the manufacturing process. Factories implement strict quality control measures to ensure that every machine meets industry standards. This involves inspecting raw materials, monitoring production processes, and testing finished products.

Technological Advancements

The metal roofing sheet making industry is undeniably influenced by technological advancements. Automation and computerization have transformed traditional manufacturing processes, resulting in increased productivity and reduced labor costs. Modern machines often come equipped with sensors and software that allow for real-time monitoring, further enhancing efficiency and reducing waste.

Furthermore, advancements in materials science have led to the development of lighter yet stronger metals, which can be utilized in roofing applications. This not only improves the performance of the roofing sheets but also contributes to the overall sustainability of construction practices.

Conclusion

Metal roofing sheet making machine factories play a pivotal role in the growing trend of metal roofing. With their advanced manufacturing processes and commitment to quality, these factories provide essential equipment that enables roofing manufacturers to meet the evolving demands of the construction industry. As technology continues to advance, it is likely that we will see even greater innovations in this field, further cementing the position of metal roofing as a preferred choice for builders and homeowners alike. The future of roofing is undoubtedly metallic, and those involved in this industry are at the forefront of a significant transformation.