metal roofing sheet machine factory

The Factory Behind Metal Roofing Sheet Machines

In the ever-evolving construction industry, the demand for durable and efficient roofing solutions has led to a burgeoning market for metal roofing. At the heart of this industry lies the manufacturing of metal roofing sheet machines, essential for producing high-quality roofing materials. This article delves into the intricacies of factories specializing in these machines, exploring their importance, production processes, and technological advancements.

Understanding Metal Roofing

Metal roofing has gained popularity due to its longevity, durability, and energy efficiency. Unlike traditional roofing materials, metal roofs can withstand extreme weather conditions, resist corrosion, and require minimal maintenance. The growing demand for sustainable building materials has made metal roofing an ideal choice for both residential and commercial constructions. However, producing roofing sheets that meet these high standards necessitates advanced machinery, leading to the establishment of specialized factories.

The Role of Metal Roofing Sheet Machines

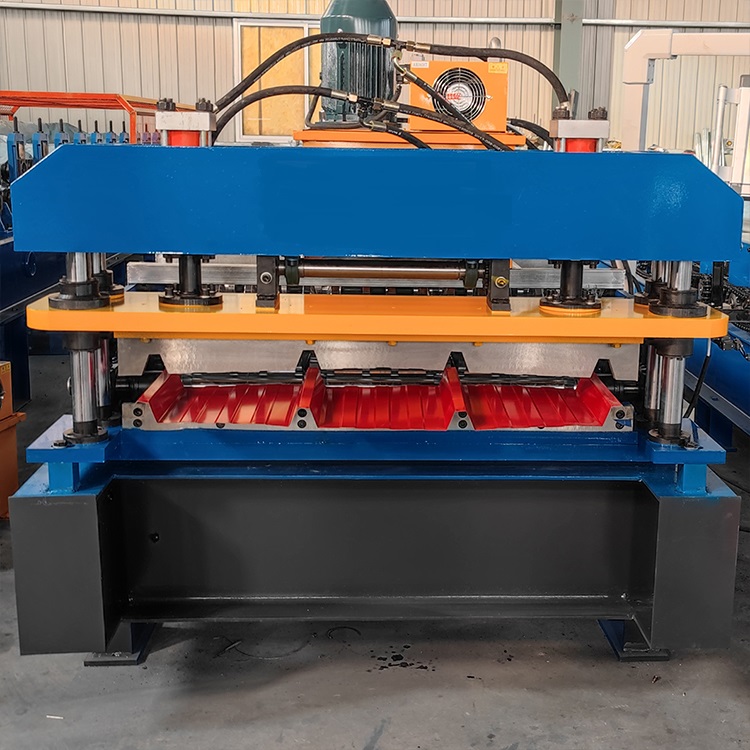

Metal roofing sheet machines are designed to convert raw metal coils into finished roofing panels. These machines can perform various processes, including cutting, bending, and shaping metal sheets, ensuring precision and quality control throughout production. The equipment typically comprises roll-forming machines, shearing machines, and other auxiliary tools that work in unison to produce consistent results.

The machines are engineered to handle different types of metal, such as steel, aluminum, and copper, allowing manufacturers to cater to diverse market needs. This versatility is crucial for ensuring that suppliers can meet the varying demands of construction projects across the globe.

The Production Process

The production process in a metal roofing sheet machine factory is a well-orchestrated sequence of steps. Initially, large coils of metal are fed into the roll-forming machines, which gradually shape the metal into specified profiles through a series of rollers. The rollers are precisely calibrated to ensure uniform thickness and consistency in the final product.

metal roofing sheet machine factory

Once the metal has been formed, it goes through a cutting process where the sheets are cut to predetermined lengths. Quality control checks are performed at various stages to ensure that the sheets meet industry standards and customer specifications. After cutting, the sheets may undergo additional processes, such as coating or painting, to enhance their aesthetic appeal and corrosion resistance.

Technological Innovations

The evolution of technology has significantly impacted the efficiency and capabilities of metal roofing sheet machines. Modern factories are increasingly integrating automation and digital control systems into their production lines. Automated machines reduce labor costs and increase production speed while maintaining high precision.

Moreover, advancements in machine design have led to the development of energy-efficient models. These machines consume less power, contributing to lower operational costs and a smaller carbon footprint. Factories are also investing in smart technology, enabling real-time monitoring of production processes and predictive maintenance, which enhances productivity and minimizes downtime.

The Factory Environment

A metal roofing sheet machine factory is not just about machines; it’s a workspace that prioritizes safety, efficiency, and environmental sustainability. Factories implement strict safety protocols to protect workers from potential hazards associated with heavy machinery and raw materials. Furthermore, many factories are adopting eco-friendly practices, such as recycling scrap metal and investing in waste reduction technologies.

In addition to the manufacturing aspect, these factories also emphasize customer service and support. Many companies offer expertise in design and engineering, helping clients choose the right materials and machinery for their specific needs. This hands-on approach fosters long-term relationships and builds trust between manufacturers and clients.

Conclusion

As the construction industry continues to prioritize durability and sustainability, the significance of metal roofing sheet machines and their factories becomes increasingly evident. With advancements in technology and a commitment to quality and safety, these factories play a vital role in shaping the future of roofing solutions. By producing high-quality metal roofing sheets, they contribute to the development of buildings that are not only resilient but also environmentally responsible. The fusion of innovation, dedication, and a focus on customer satisfaction ensures that metal roofing will remain a prominent choice among builders and homeowners alike.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025