Quality Metal Roofing Roll Forming Machines for Sale from Leading Manufacturer

Metal Roofing Roll Forming Machines for Sale A Comprehensive Guide

In the ever-evolving construction industry, metal roofing has gained significant popularity due to its durability, energy efficiency, and aesthetic appeal. As the demand for metal roofing continues to rise, so does the need for efficient manufacturing equipment. One of the crucial tools in this sector is the metal roofing roll forming machine. These machines streamline the production process and ensure high-quality roofing materials, thus catering to the growing market.

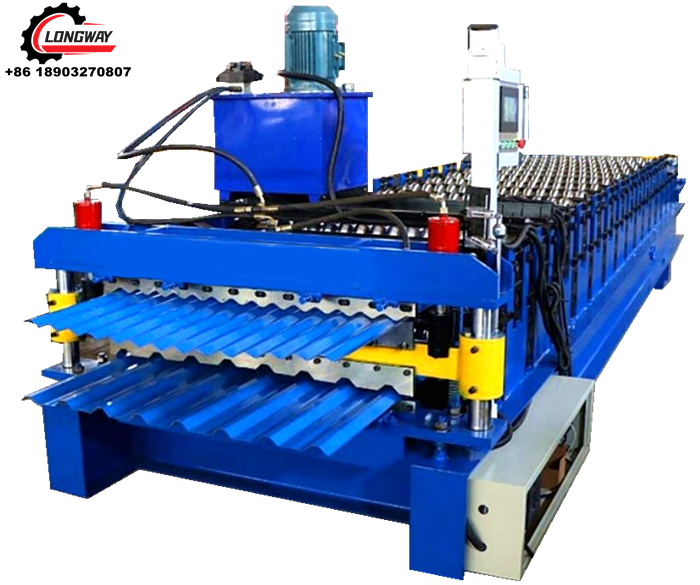

Metal roofing roll forming machines are designed to convert flat metal sheets into various roofing profiles. These machines work by feeding metal coils into a series of rollers, which shape the metal into the desired profile. This process significantly reduces labor costs and boosts production efficiency, making it a popular choice among manufacturers. There are various types of roll forming machines available, each tailored for specific applications and materials, including steel, aluminum, and copper.

When considering a purchase, manufacturers should evaluate the specifications of the machines on offer. Key factors to consider include the machine’s production capacity, the types of profiles it can produce, and its overall ease of use. A good roll forming machine should be user-friendly and come with advanced features, such as automated controls, which can enhance productivity. Additionally, look for machines that offer versatility, allowing the production of multiple roofing profiles without the need for extensive adjustments.

metal roofing roll forming machines for sale manufacturer

There are numerous manufacturers worldwide offering metal roofing roll forming machines for sale. It is essential to choose a reputable supplier with a proven track record in the industry. Reviews and testimonials can provide insights into the reliability and efficiency of the machines. Furthermore, inquire about after-sales services, including maintenance and technical support, as these can significantly impact the long-term performance of the equipment.

Another aspect to consider is the financial investment. While the initial cost of acquiring a roll forming machine can be substantial, it’s important to assess the long-term benefits. A high-quality machine can lead to increased production rates and reduced waste, ultimately enhancing profitability. Additionally, some manufacturers offer financing options, which can help ease the burden of upfront costs.

In conclusion, investing in metal roofing roll forming machines can be a game-changer in the roofing industry. By optimizing production processes and offering high-quality products, manufacturers can meet the demands of an expanding market. With a variety of options available, thorough research and careful consideration will lead to the right choice for any business looking to enhance its manufacturing capabilities.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025