metal roofing roll forming machines for sale company

The Rise of Metal Roofing Roll Forming Machines in Construction

In recent years, the construction industry has witnessed a significant transformation, particularly in roofing materials. Among the various options available, metal roofing has gained immense popularity due to its durability, energy efficiency, and aesthetic appeal. As demand for metal roofing continues to rise, the role of metal roofing roll forming machines has become increasingly vital. Companies specializing in the sale and manufacturing of these machines play a crucial role in meeting this growing need.

What are Metal Roofing Roll Forming Machines?

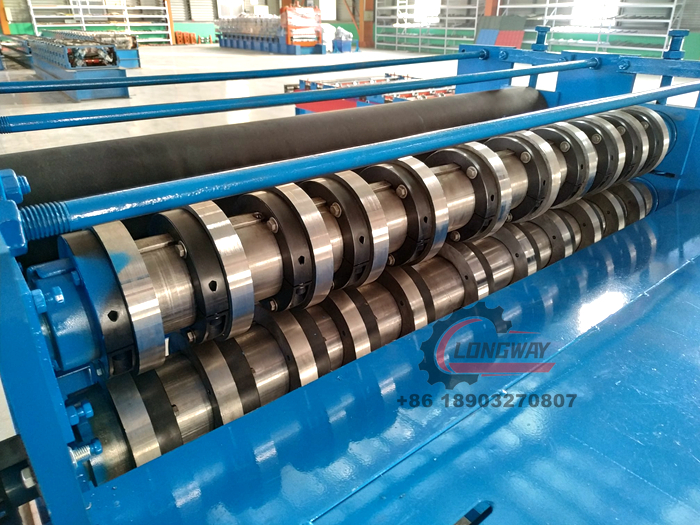

Metal roofing roll forming machines are specialized equipment used to fabricate metal roofing panels in various profiles and lengths. These machines are designed to take flat metal sheets and pass them through a series of rollers, which shape the sheet into a specific profile. The result is a highly customized roofing product that can suit different architectural styles and functional requirements.

The versatility of these machines allows manufacturers to produce a wide range of products, including standing seam panels, corrugated sheets, and shingles. Moreover, advancements in technology have enabled the incorporation of features like automated cutting, adjustable forming speeds, and easy to operate digital controls, thereby enhancing efficiency and precision in production.

The Growing Demand for Metal Roofing

The increasing focus on sustainable construction has significantly boosted the popularity of metal roofing. Metal roofs are not only long-lasting and resistant to extreme weather conditions but also highly recyclable, promoting environmental sustainability. Additionally, they provide excellent insulation properties, reducing energy costs for heating and cooling.

The aesthetics of metal roofing have also played a role in its rise in popularity. Available in a variety of colors and finishes, metal roofs can enhance the visual appeal of both residential and commercial properties. This has led to a greater acceptance of metal roofs in traditionally non-metal roofing markets.

Why Invest in Metal Roofing Roll Forming Machines?

For companies engaged in the construction industry or those looking to expand into roofing solutions, investing in metal roofing roll forming machines can be a wise business decision. Here are several key benefits

metal roofing roll forming machines for sale company

1. Cost Efficiency Owning a roll forming machine allows manufacturers to produce roofing panels in-house, significantly reducing costs associated with purchasing pre-made materials. By controlling the manufacturing process, companies can also minimize waste and optimize material usage.

2. Customization With the ability to quickly change profiles and adjust machine settings, manufacturers can respond to demand for various roofing styles and preferences. This flexibility can set a company apart from competitors who may be limited to standard products.

3. Quality Control Owning production machinery enables companies to maintain stringent quality control over their products. This ensures that the roofing materials not only meet but exceed industry standards in durability and performance.

4. Rapid Production Roll forming machines can produce metal roofing panels at a much faster rate than traditional methods. This speed allows companies to cater to larger projects and meet tight deadlines without compromising quality.

Finding the Right Company for Purchase

When searching for metal roofing roll forming machines for sale, it is essential to choose a reputable manufacturer. Look for companies with a proven track record of quality, customer support, and innovative technology. Additionally, consider factors such as warranty, after-sales service, and available upgrades to ensure that your investment is protected.

Many manufacturers offer customizable machines tailored to specific production requirements, providing a unique solution tailored to individual business needs. Moreover, some companies provide training and support to ensure that operators are well-versed in machine operation and maintenance.

Conclusion

As the demand for metal roofing continues to surge, the importance of high-quality metal roofing roll forming machines cannot be understated. By investing in these machines, companies can enhance their operational efficiency, reduce costs, and meet diverse customer needs. With a wide array of options available from various manufacturers, businesses have the opportunity to streamline their production processes and become key players in the ever-evolving construction landscape. Embracing this technological advancement not only fosters growth but also positions companies at the forefront of sustainable building practices in the roofing industry.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025