metal roofing roll forming machine factory

Metal Roofing Roll Forming Machine Factory Revolutionizing Metal Roofing Production

In today’s fast-paced construction industry, efficiency, durability, and sustainability are at the forefront of building material innovations. Among these innovations, metal roofing stands out as an optimal choice for various architectural needs. At the heart of this burgeoning sector lies the metal roofing roll forming machine factory, a facility dedicated to the production of cutting-edge equipment that transforms raw metal sheets into precision-engineered roofing panels.

The Role of Metal Roofing in Modern Construction

Metal roofing is increasingly popular due to its durability, energy efficiency, and low maintenance requirements. Whether it’s standing seam roofs or corrugated panels, metal offers a plethora of benefits over traditional materials like asphalt or wood. It can withstand harsh weather conditions, is fire-resistant, and reflects solar energy, contributing to energy savings and environmental sustainability. As the demand for such roofing solutions grows, so does the need for advanced manufacturing equipment.

The Importance of Roll Forming Machines

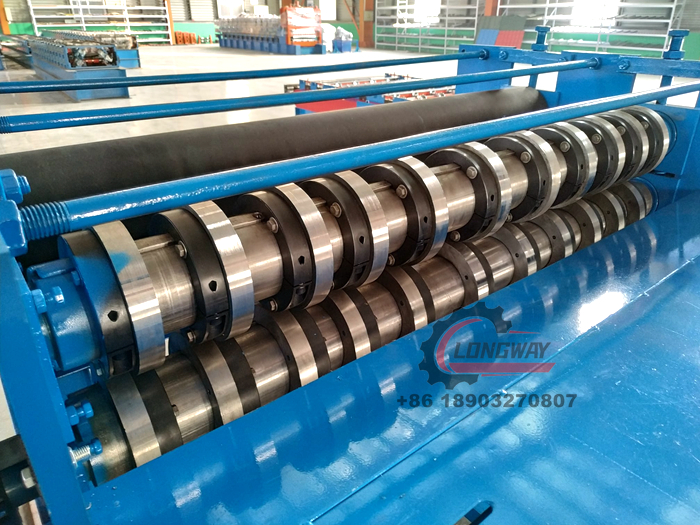

Roll forming machines are essential in the process of creating metal roofing panels. These machines are designed to continuously shape metal strips or sheets into specific profiles through a series of rollers. The roll forming process is highly efficient, allowing manufacturers to produce high volumes of roofing panels with consistent quality and dimensional accuracy.

A typical roll forming machine consists of a series of rollers that progressively bend the metal into the desired shape. This process not only ensures uniformity in thickness and profile but also minimizes waste, making it a cost-effective solution for manufacturers.

Features of Modern Metal Roofing Roll Forming Machines

The machines produced in a metal roofing roll forming machine factory come equipped with several advanced features

1. Customization Options Many factories offer machines that can be customized to meet specific production needs. This includes the ability to create different profiles, sizes, and gauges of metal panels, allowing manufacturers to cater to a diverse range of client requirements.

2. Automation and Control Systems Modern roll forming machines often incorporate advanced automation technologies, including computerized controls and programmable logic controllers (PLCs). These features enhance the precision of the forming process and reduce labor costs, allowing for more efficient production lines.

metal roofing roll forming machine factory

3. High Production Capacity With improvements in technology, contemporary roll forming machines are capable of producing a large number of panels in a relatively short timeframe. This efficiency is essential for meeting the increasing demand for metal roofing solutions in the construction sector.

4. Durability and Reliability Machines manufactured in dedicated factories are constructed from high-quality materials, ensuring longevity and reliability. These machines are built to withstand the rigors of continuous operation without compromising on performance.

The Manufacturing Process in the Factory

The production of metal roofing roll forming machines involves several stages

1. Design and Engineering Skilled engineers design the machine’s structure and components using advanced CAD software, ensuring that each part functions seamlessly together.

2. Material Selection and Fabrication The factory sources high-quality steel and other materials for production. Each component is fabricated with precision, often using CNC machinery for accuracy.

3. Assembly After fabrication, the components are assembled into the final machine. This stage requires meticulous attention to detail to ensure that all moving parts operate efficiently.

4. Testing and Quality Control Before the machines leave the factory, they undergo rigorous testing to ensure they meet industry standards. Quality control checks are crucial to ensure durability and performance.

Conclusion

A metal roofing roll forming machine factory plays a pivotal role in the construction industry by providing essential machinery that facilitates the production of high-quality metal roofing solutions. As the demand for metal roofs continues to rise, so will the importance of these factories in driving innovation and efficiency. By investing in advanced roll forming technology, manufacturers can deliver superior products that not only meet but exceed the expectations of builders and homeowners alike. As we move towards a more sustainable future, the impact of metal roofing and the machines that produce it will undoubtedly grow, shaping the skylines of tomorrow.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025