metal roofing roll forming machine companies

The Rise of Metal Roofing Roll Forming Machine Companies

In recent years, the construction industry has witnessed a substantial shift towards metal roofing solutions. As sustainability and durability become paramount concerns for builders and homeowners alike, metal roofs have gained popularity due to their energy efficiency, longevity, and aesthetic versatility. A crucial component of this burgeoning market is the technological advancement in metal roofing roll forming machines. These machines have transformed the way metal roofing panels are produced, leading to a surge in metal roofing roll forming machine companies.

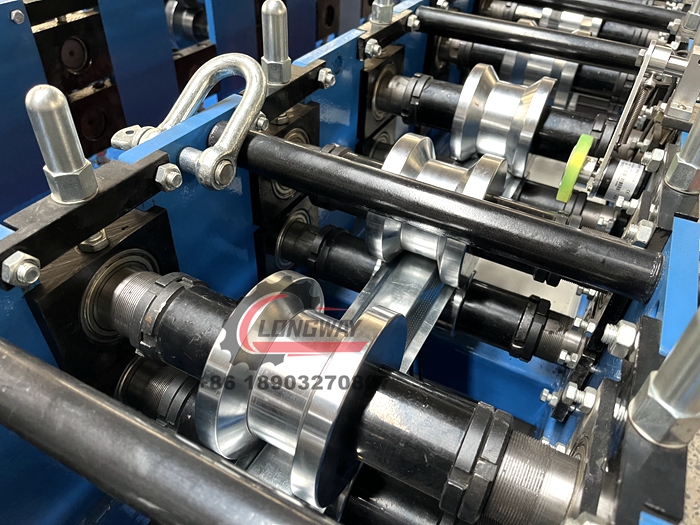

What is a Metal Roofing Roll Forming Machine?

A metal roofing roll forming machine is a specialized piece of equipment designed to convert metal coils into roofing sheets. This process involves a series of rolls that shape the flat metal into the desired profile, allowing for the creation of various designs tailored to specific architectural needs. The machines can produce a range of roofing styles, from standing seam panels to corrugated sheets, making them invaluable for manufacturers in the metal roofing sector.

Key Players in the Industry

As the demand for metal roofing continues to rise, numerous companies have emerged as key players in the roll forming machine market. These companies range from small businesses to large-scale manufacturers, each offering unique features and benefits in their products. Some of the leaders in this industry include

1. Bäcker-Rollform Known for its precision machinery, Bäcker-Rollform has set a high standard in the industry. Their machines are designed for efficiency and ease of use, enabling operators to produce high-quality roofing panels with minimal labor.

2. Forming Technologies This company focuses on innovative and customized roll forming solutions. Their machines are capable of producing complex profiles, catering to architects and builders looking for unique roofing designs.

3. Hutchinson Manufacturing With decades of experience, Hutchinson Manufacturing provides robust and reliable roll forming machines. Their emphasis on durability ensures that their machines can withstand continuous operation, making them a favorite among roofing companies.

metal roofing roll forming machine companies

4. Cleveland Steel & Tubes This company not only manufactures roll forming machines but also provides comprehensive training and support services for its clients. Their commitment to customer satisfaction has earned them a loyal customer base.

Advantages of Using Roll Forming Machines

Metal roofing roll forming machines offer several advantages for manufacturers and contractors alike. First and foremost, these machines significantly reduce labor costs. The automation of the roll forming process allows for faster production speeds, making it possible to meet tight deadlines without compromising quality.

Furthermore, roll forming technology ensures that roofing panels are accurately produced to specification, reducing material waste and improving overall efficiency. Additionally, operators can easily adjust the machine settings to create different profiles, allowing for design flexibility without requiring extensive downtime or major equipment changes.

The Future of Metal Roofing Roll Forming Machines

The future of metal roofing roll forming machine companies looks promising, driven by advancements in technology and a growing focus on sustainability. As green building practices gain traction, more builders are turning to metal roofing solutions, leading to increased demand for specialized machinery.

Moreover, innovations such as computer numerical control (CNC) technology are being integrated into roll forming machines, enhancing precision and enabling manufacturers to produce more complex designs with ease. The shift towards smart manufacturing, incorporating IoT (Internet of Things) technology, is also on the horizon, allowing real-time monitoring and maintenance of machines, thus improving productivity and reducing downtime.

Conclusion

Metal roofing roll forming machine companies are at the forefront of an evolving construction landscape. With advancements in technology and a growing demand for sustainable building solutions, these companies play a critical role in shaping the future of the roofing industry. As they continue to innovate and respond to market needs, the potential for growth and development in this sector is immense. For manufacturers and contractors, investing in quality roll forming machinery is more than just a business decision; it is a commitment to quality, efficiency, and sustainability in a competitive market.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025