Feb . 05, 2025 05:20

Back to list

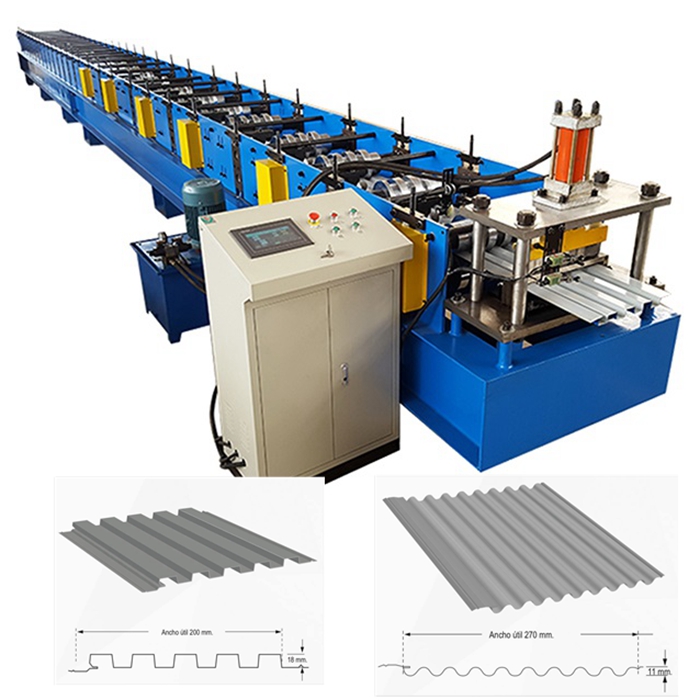

T18 C18 Metal roofing machine Roof sheet forming machine

The world of metal roofing has evolved significantly, with roll forming machines playing a critical role in this development. As someone who has witnessed firsthand the transformative power of metal roofing roll forming machines, I can testify to their pivotal role in efficiency, precision, and sustainability in the roofing industry.

Trustworthiness is another fundamental pillar of these machines. Manufacturers invest heavily in research and development to ensure their machines comply with the highest standards of quality and safety. This commitment builds confidence amongst users, as they know that the products they are installing are safe, reliable, and built to last. The real-world application of metal roofing roll forming machines has significantly shifted the global roofing landscape. A case in point is a large-scale commercial project I was involved with, where the use of these machines reduced project time by nearly 30%. The speed and efficiency with which the roofing could be fabricated and installed not only met but exceeded client expectations. This experience is a testament to how these machines have become indispensable tools in modern construction. Finally, the sustainability factor cannot be overlooked. With more focus than ever on environmentally friendly construction practices, metal roofing is gaining popularity for its recyclability and energy efficiency. Metal roofing roll forming machines enable the production of roofing panels that not only perform exceptionally well in thermal regulation but also significantly reduce the carbon footprint during the manufacturing process itself. As we look towards a future where efficiency, durability, and sustainability are paramount, metal roofing roll forming machines position themselves as leaders in the construction industry. Their role in producing high-quality, versatile, and environmentally friendly roofing solutions makes them not only a technological marvel but also a vital component in creating resilient and sustainable infrastructure worldwide.

Trustworthiness is another fundamental pillar of these machines. Manufacturers invest heavily in research and development to ensure their machines comply with the highest standards of quality and safety. This commitment builds confidence amongst users, as they know that the products they are installing are safe, reliable, and built to last. The real-world application of metal roofing roll forming machines has significantly shifted the global roofing landscape. A case in point is a large-scale commercial project I was involved with, where the use of these machines reduced project time by nearly 30%. The speed and efficiency with which the roofing could be fabricated and installed not only met but exceeded client expectations. This experience is a testament to how these machines have become indispensable tools in modern construction. Finally, the sustainability factor cannot be overlooked. With more focus than ever on environmentally friendly construction practices, metal roofing is gaining popularity for its recyclability and energy efficiency. Metal roofing roll forming machines enable the production of roofing panels that not only perform exceptionally well in thermal regulation but also significantly reduce the carbon footprint during the manufacturing process itself. As we look towards a future where efficiency, durability, and sustainability are paramount, metal roofing roll forming machines position themselves as leaders in the construction industry. Their role in producing high-quality, versatile, and environmentally friendly roofing solutions makes them not only a technological marvel but also a vital component in creating resilient and sustainable infrastructure worldwide.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products