metal roofing roller machine factory

The Role of Metal Roofing Roller Machine Factories in Modern Construction

In the ever-evolving landscape of construction, the demand for durable and efficient roofing solutions has led to a significant rise in the use of metal roofing materials. Among the key players in this industry are metal roofing roller machine factories, which specialize in manufacturing the machines that produce the intricate metal sheets used for roofing. This article delves into the importance of these factories, the technology behind metal roofing roller machines, and the impact they have on both the construction industry and consumers.

The Importance of Metal Roofing

Metal roofing has gained popularity due to its inherent advantages. It is highly durable, capable of withstanding extreme weather conditions, and requires minimal maintenance compared to traditional roofing materials like asphalt shingles or tiles. Additionally, metal roofs reflect solar radiant heat, which can significantly reduce cooling costs in warm climates. As more builders and homeowners realize these benefits, the demand for metal roofing has soared.

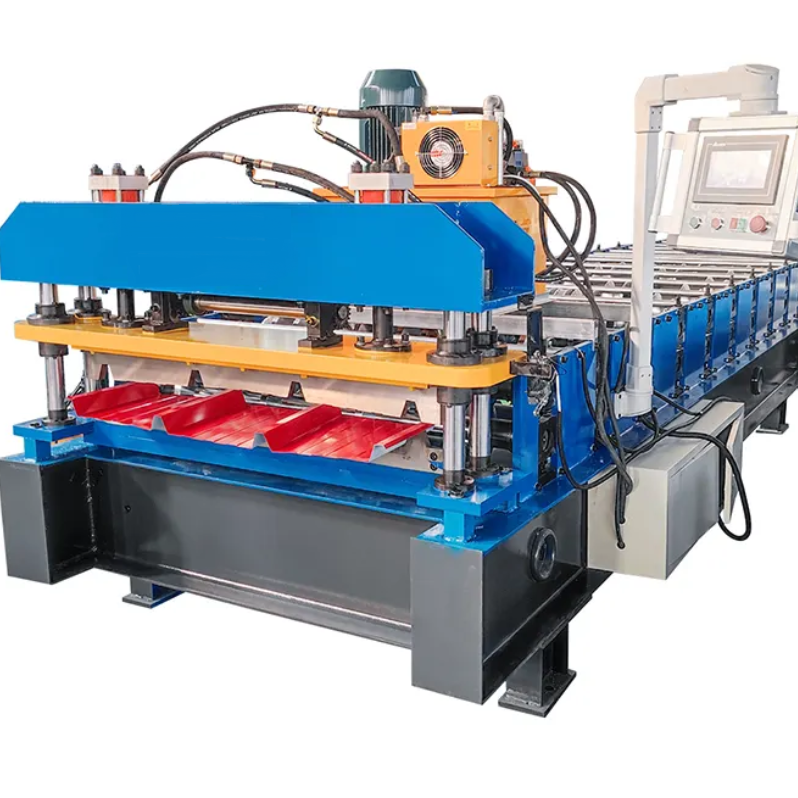

To meet this rising demand, metal roofing roller machine factories play a vital role. These facilities produce specialized machinery that shapes metal coils into roofing panels of various styles and specifications. The efficiency and precision of these machines ensure that the metal sheets fit together seamlessly, creating a robust roofing solution that can last for decades.

Technology Behind Metal Roofing Roller Machines

Metal roofing roller machines employ advanced technology to achieve high levels of precision and efficiency. The process begins with metal coils, which are fed into the machine. As the coils move through the roller system, they are shaped and cut to the desired specifications. The technology used in these machines often includes computerized controls that allow for quick adjustments, ensuring that the production process is flexible enough to accommodate different designs and dimensions.

metal roofing roller machine factory

Furthermore, many modern roller machines are equipped with features such as automatic feeding systems, integrated cutting tools, and quality control mechanisms. These enhancements not only streamline the production process but also improve the overall product quality, resulting in roofing panels that meet and exceed industry standards.

Impact on the Construction Industry

The impact of metal roofing roller machine factories extends beyond just the production of roofing panels. By providing manufacturers with advanced tools and technologies, these factories contribute to the overall efficiency of the construction industry. Faster production times mean that contractors can complete projects more quickly, leading to reduced labor costs and increased profitability.

Moreover, as the trend towards sustainable building practices continues to grow, metal roofing offers an eco-friendly solution. Many metal roofing materials are made from recycled content, and the longevity of metal roofs means that they don’t need to be replaced as often as traditional materials. This sustainability aspect further enhances the appeal of metal roofing, driving greater demand for roller machines capable of producing high-quality products.

Conclusion

In conclusion, metal roofing roller machine factories are integral to the modern construction landscape. They provide the technology necessary to meet the growing demand for metal roofing, a material recognized for its durability and energy efficiency. As the construction industry continues to evolve, these factories will play a critical role in advancing manufacturing processes, ensuring that builders have access to the highest quality roofing solutions on the market. With their commitment to technology and quality, metal roofing roller machine factories are helping to shape the future of construction one roof at a time.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025