Cost Analysis of Metal Roofing Machinery from Leading Manufacturers and Suppliers

When considering the construction or renovation of a building, choosing the right roofing material can be an essential decision. Metal roofing has become increasingly popular due to its durability, energy efficiency, and aesthetic appeal. However, understanding the costs associated with metal roofing machines and the various companies that manufacture them is crucial for proper budgeting and decision-making.

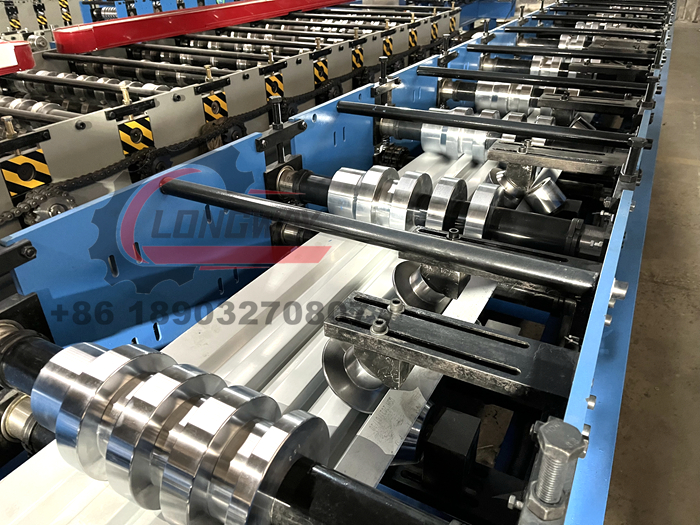

Metal roofing machines are specialized equipment designed to produce metal roofing panels and accessories on-site. This can significantly reduce costs, as purchasing pre-made panels often involves substantial shipping fees and markups from suppliers. By investing in a metal roofing machine, contractors and builders can create custom lengths, styles, and colors to meet specific project requirements.

The cost of metal roofing machines can vary widely based on the type of machine, its capabilities, and the manufacturer. Basic machines designed for producing corrugated metal panels can start at around $10,000, while more advanced systems capable of creating standing seam roofing can range from $30,000 to over $100,000. High-end machines may offer additional features such as automated adjustments for different panel designs, computer controls for efficiency, and enhanced safety mechanisms.

When looking at companies that produce metal roofing machines, it's essential to consider their reputation and the level of support they offer. Established manufacturers often provide comprehensive warranties, training programs, and ongoing technical support, which can be invaluable, especially for new operators. Some well-known companies in the industry include MetalForming Inc., Bradbury Group, and B & B Machinery. Each of these companies offers a range of machines catering to different needs and budgets.

metal roofing machine cost companies

Additionally, it’s important to evaluate the total ownership cost of the machine. This includes not only the initial purchase price but also maintenance, operating costs, and potential downtime if the equipment requires repairs. Investing in a quality machine often pays off in the long run by reducing material waste and improving production efficiency.

Furthermore, understanding the market demand for metal roofing can help gauge whether investing in a metal roofing machine is worthwhile. As the trend toward sustainable building increases, the demand for metal roofs is expected to rise. This makes it an opportune time for contractors to consider the benefits of metal roofing machines.

In conclusion, investing in metal roofing machines can be a significant decision for contractors and builders. Understanding the costs involved and researching reputable companies can lead to better financial outcomes and project success. By carefully considering the options available, builders can take advantage of the growing demand for metal roofing while ensuring high-quality results on every project.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025