metal roofing machine cost companies

The Cost of Metal Roofing Machines A Comprehensive Overview

Metal roofing has become increasingly popular over the years due to its durability, aesthetic appeal, and energy efficiency. As the demand for metal roofs continues to rise, so does the need for efficient manufacturing tools, particularly metal roofing machines. These machines are essential for roofing companies looking to produce high-quality metal panels quickly and efficiently. However, understanding the cost associated with acquiring a metal roofing machine can be daunting. In this article, we will explore the factors affecting the cost of metal roofing machines and the companies that manufacture them.

Types of Metal Roofing Machines

Before diving into costs, it is important to understand the different types of metal roofing machines available on the market. The most common types include

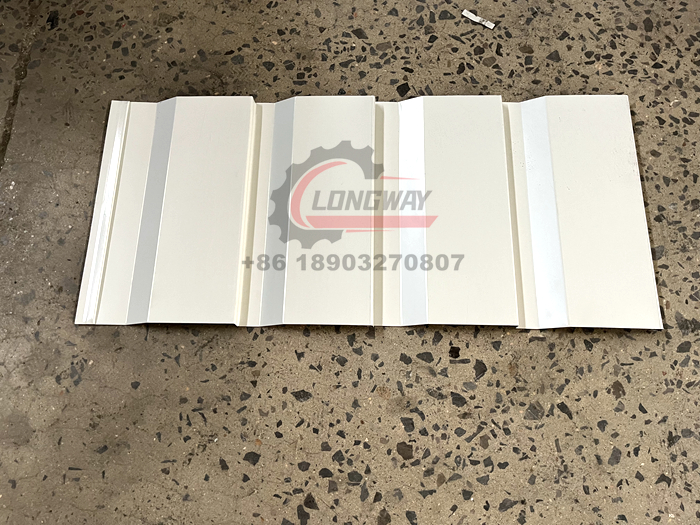

1. Roll Forming Machines These machines are used to create metal panels by continuously forming metal sheets into the desired shape. They are widely used in the production of standing seam and corrugated metal roofing panels.

2. Shearing Machines Shearing machines are designed to cut metal sheets to specific lengths and widths, ensuring accuracy in production.

3. Notching Machines Notching machines are used to create specific shapes or cutouts in metal sheets, allowing for more intricate designs and efficient installation.

4. Slitting Machines These machines are used to cut wide metal coils into narrower strips, which can then be formed into panels or sheets.

Factors Affecting Costs

Several factors influence the cost of metal roofing machines, and understanding these can help roofing companies make informed purchasing decisions

1. Machine Type As mentioned above, the type of machine required will significantly impact the cost. Roll forming machines tend to be more expensive due to their complexity, while shearing machines might be more affordable.

metal roofing machine cost companies

2. Brand and Manufacturer Different companies manufacture metal roofing machines, each with its own price range. Established manufacturers may offer higher prices due to the reputation and reliability of their machines, while newer or less-known brands may provide more budget-friendly options.

3. Customization If a company requires customized features or designs in their metal roofing machine, the cost will typically increase. Customization can include specific dimensions, unique production capabilities, or advanced technology integrations.

4. Production Capacity Machines with a higher production capacity typically come with a higher price tag. Companies must assess their production needs to determine the appropriate machine that balances cost and capacity.

5. Technology and Automation Advanced machines with cutting-edge technology and automation capabilities can significantly drive up the cost. While these machines might represent a higher initial investment, they can lead to increased efficiency and reduced labor costs in the long run.

6. Warranty and Support When purchasing a metal roofing machine, companies should consider the warranty and support offered by the manufacturer. A more extended warranty and better support services usually mean higher costs but can provide greater peace of mind.

Average Cost Ranges

On average, metal roofing machines can range in price from $10,000 to over $100,000, depending on the factors mentioned above. Smaller, more basic machines may be available for around $10,000 to $20,000, while more advanced machines with high production capabilities can exceed $100,000. Additionally, some high-end machines with extensive customization options can even reach upwards of $200,000.

Finding the Right Supplier

When searching for a metal roofing machine supplier, companies should conduct thorough research to ensure they find a reputable manufacturer. It is advisable to look for reviews, testimonials, and case studies from other roofing companies to gauge the reliability and performance of the machines. Additionally, visiting trade shows or industry exhibitions can provide insights into the latest technologies and help establish connections with suppliers.

Conclusion

Investing in a metal roofing machine is a significant decision for any roofing company. Understanding the various types of machines, the factors influencing their costs, and the available suppliers is essential for making an informed choice. By carefully considering these elements, roofing companies can ensure they select the right machine that meets their production needs while staying within budget. As the market for metal roofing continues to grow, the right machinery can position a company for success and efficiency in an increasingly competitive industry.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025