metal roof forming machine manufacturers

The Rise of Metal Roof Forming Machine Manufacturers Transforming the Construction Industry

In recent years, the construction industry has seen a significant shift towards metal roofing systems. This trend is largely attributed to metals' durability, energy efficiency, and aesthetic versatility. As a result, the demand for metal roof forming machines has soared, giving rise to a multitude of manufacturers specializing in this sector.

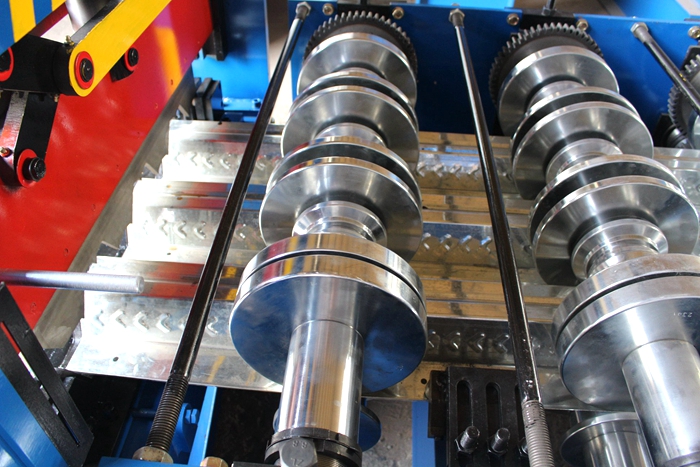

Metal roof forming machines are designed to produce metal roofing sheets that meet various architectural and structural needs. The process involves the continuous roll forming of metal strips into desired profiles, which are then cut to specific lengths. This manufacturing process not only streamlines production but also ensures precision and consistency, which are crucial for quality roofing applications.

The Importance of Metal Roof Forming Machines

Metal roofing offers several advantages over traditional roofing materials. They are lightweight, resistant to extreme weather conditions, and can significantly lower energy costs. Furthermore, metal roofs are recyclable, making them an ecologically responsible choice. As construction projects increasingly focus on sustainability, the role of metal roof forming machines becomes even more pivotal.

Manufacturers of these machines play a crucial role in supporting the metal roofing demand. They are responsible for equipping contractors and construction firms with the tools necessary to fabricate roofing materials that are both reliable and cost-effective. As the market continues to expand, many manufacturers are innovating by integrating advanced technologies into their machines, such as automation and IoT connectivity. These innovations enhance production efficiency and provide real-time monitoring and maintenance alerts, which can significantly reduce downtime.

Key Features of Quality Metal Roof Forming Machines

When considering metal roof forming machines, several characteristics are essential to assess quality and capability. First and foremost, the machine's robustness and durability are critical; high-quality materials and construction directly impact the machine's lifespan and productivity.

metal roof forming machine manufacturers

Additionally, flexibility in design is crucial. Manufacturers increasingly offer machines that can produce multiple profiles and styles, allowing users to cater to a variety of customer preferences. This feature not only broadens market reach but also reduces the need for multiple machines, thereby lowering investment costs for roofing businesses.

Moreover, efficient production speed is vital. High-speed machines can significantly boost output, enabling contractors to complete projects more quickly. For manufacturers, offering machines with adjustable speeds can cater to both large-scale projects and smaller jobs with varying production demands.

The Competitive Landscape of Metal Roof Forming Machine Manufacturers

Today, the market is home to numerous manufacturers specializing in metal roof forming machines. This intense competition drives innovation and keeps prices competitive. Leading companies often offer comprehensive support and training services, ensuring clients can maximize their investments and maintain high productivity levels.

Moreover, geographical diversification is an essential strategy for many manufacturers. By establishing facilities in different regions, they can better serve local markets while minimizing shipping costs and lead times. This localized approach not only improves customer satisfaction but also helps companies respond swiftly to shifting market demands.

Conclusion

As the construction industry continues to embrace metal roofing solutions, the role of metal roof forming machine manufacturers becomes increasingly vital. Their innovations and advancements enable the production of high-quality roofing materials tailored to meet modern demands. With a strong focus on durability, efficiency, and market adaptability, these manufacturers are not just keeping pace with current trends—they are shaping the future of roofing solutions. For contractors and construction firms looking to thrive in this competitive landscape, investing in cutting-edge metal roof forming machines is no longer just an option; it is a strategic imperative.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025