Jan . 13, 2025 11:42

Back to list

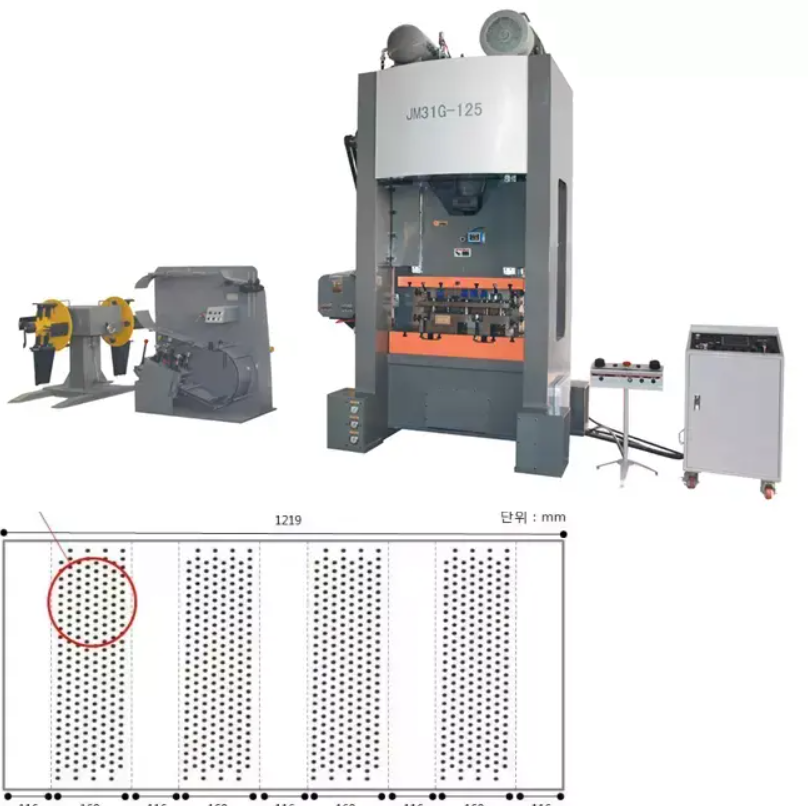

metal roof forming machine

The advancement of technology in construction tools has dramatically shifted the landscape of building methodologies, and among these innovations, the metal roof forming machine stands out prominently. As a seasoned professional in the domain of roofing solutions, having years of experience in implementing varied roofing techniques, the insights shared here are rooted deeply in real-world application and astute expertise.

In terms of authoritativeness, the endorsement of metal roof forming machines by industry leaders speaks volumes about their reliability and effectiveness. Top-tier architects and construction companies often reference these machines as indispensable tools that add significant value to both residential and commercial projects. Their capability to churn out panels at scale without compromising on the quality or performance of the roofing material positions them as a superior choice over less sophisticated methods. Trustworthiness is another foundational pillar established by the consistent performance of metal roof forming machines in challenging scenarios across the globe. From hurricane-prone areas requiring robust roofs to withstand extreme wind pressures, to industrial zones necessitating durable shielding against harsh weather, the trust placed in these machines is continually reaffirmed by their performance. Manufacturers and seasoned operators offer extensive warranties and maintenance services, reinforcing this trust and ensuring the machines function optimally across different project conditions. The return on investment when employing a metal roof forming machine is notable, both in the long-term savings on materials and the longevity of the roof structures created. Many users, particularly those involved in large-scale construction projects, report substantial cost savings due to reduced material wastage and minimized labor expenses. This level of cost-effectiveness is exemplified in the long-term durability and minimal maintenance requirements of the roofs produced, underscoring the financial prudence of investing in such technological advancements. Thus, the metal roof forming machine is more than just an apparatus; it is a revolution in roofing technology. Its precision, efficiency, adaptability, and reliability encapsulate the ethos of modern construction—building stronger, more resilient structures while optimizing resources. For those looking to leverage contemporary technology in the realm of construction, investing in a metal roof forming machine is not just a decision; it’s a strategic move that aligns with the contemporary demands of quality, sustainability, and efficiency.

In terms of authoritativeness, the endorsement of metal roof forming machines by industry leaders speaks volumes about their reliability and effectiveness. Top-tier architects and construction companies often reference these machines as indispensable tools that add significant value to both residential and commercial projects. Their capability to churn out panels at scale without compromising on the quality or performance of the roofing material positions them as a superior choice over less sophisticated methods. Trustworthiness is another foundational pillar established by the consistent performance of metal roof forming machines in challenging scenarios across the globe. From hurricane-prone areas requiring robust roofs to withstand extreme wind pressures, to industrial zones necessitating durable shielding against harsh weather, the trust placed in these machines is continually reaffirmed by their performance. Manufacturers and seasoned operators offer extensive warranties and maintenance services, reinforcing this trust and ensuring the machines function optimally across different project conditions. The return on investment when employing a metal roof forming machine is notable, both in the long-term savings on materials and the longevity of the roof structures created. Many users, particularly those involved in large-scale construction projects, report substantial cost savings due to reduced material wastage and minimized labor expenses. This level of cost-effectiveness is exemplified in the long-term durability and minimal maintenance requirements of the roofs produced, underscoring the financial prudence of investing in such technological advancements. Thus, the metal roof forming machine is more than just an apparatus; it is a revolution in roofing technology. Its precision, efficiency, adaptability, and reliability encapsulate the ethos of modern construction—building stronger, more resilient structures while optimizing resources. For those looking to leverage contemporary technology in the realm of construction, investing in a metal roof forming machine is not just a decision; it’s a strategic move that aligns with the contemporary demands of quality, sustainability, and efficiency.

Latest news

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025

Related Products