metal roof cutting machine factory

The Role of Metal Roof Cutting Machine Factories in the Construction Industry

In the modern construction landscape, efficiency and precision are paramount. Among the numerous tools and machines that facilitate construction processes, metal roof cutting machines have carved a niche for themselves, playing a crucial role in the Roofing industry. Metal roof cutting machine factories are at the heart of this sector, manufacturing equipment designed to meet the growing demand for innovative and high-quality roofing solutions.

Understanding Metal Roof Cutting Machines

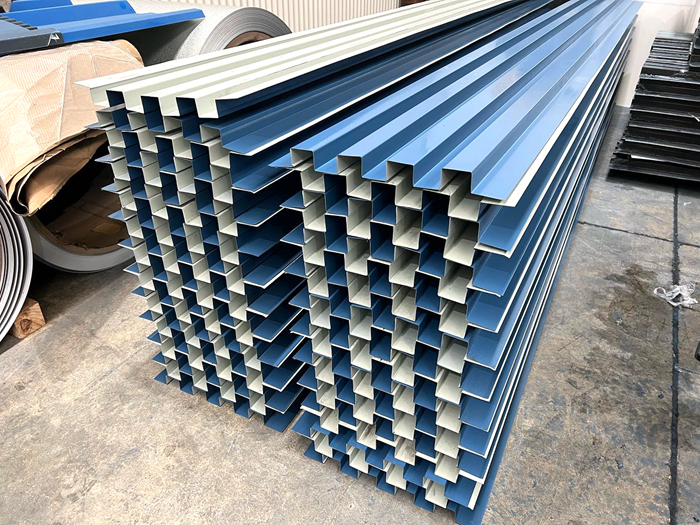

Metal roof cutting machines are specialized tools designed to cut various types of metal sheets used in roofing applications. These machines cater to diverse materials, including steel, aluminum, copper, and zinc, each of which has distinct characteristics and requires specific cutting techniques. The primary function of these machines is to deliver fast, accurate, and efficient cuts, contributing to the construction of durable and aesthetically pleasing roofs.

There are various types of metal roof cutting machines, including hydraulic shear machines, plasma cutting systems, and laser cutters. Each type serves a particular purpose, with varying degrees of precision, speed, and ease of operation. For instance, laser cutting machines are highly favored for their accuracy and clean cuts, making them ideal for intricate designs.

Importance of Metal Roof Cutting Machine Factories

Metal roof cutting machine factories are vital for several reasons. Firstly, they contribute significantly to the overall efficiency of the construction industry. By producing high-quality cutting machines, these factories enable roofing contractors to complete jobs faster and with greater accuracy. This efficiency translates to cost savings, as projects can be completed in less time without compromising on quality.

Moreover, these factories often invest in research and development to create machines that incorporate the latest technological advancements. Features like programmable controls, user-friendly interfaces, and automation enhance the functionality of metal roof cutting machines. As a result, manufacturers can produce roofing materials that not only meet but exceed industry standards.

The Economic Impact

metal roof cutting machine factory

The economic implications of metal roof cutting machine factories extend beyond the immediate construction projects. The machinery produced by these factories supports a wide range of industries, from residential and commercial construction to industrial applications. As demand for metal roofing rises, driven by its longevity, energy efficiency, and aesthetic appeal, the factories are positioned to thrive.

Additionally, the manufacturing processes involved in producing these machines create job opportunities. Skilled labor is required to operate, maintain, and design cutting machines. This generates a demand for training programs and educational initiatives, further benefiting local economies.

Environmental Considerations

As awareness of environmental issues grows, metal roof cutting machine factories are also adapting to sustainable practices. The industry is seeing a shift towards the use of eco-friendly materials and processes. Many manufacturers now focus on creating machines that minimize waste, recycle materials, and reduce energy consumption. This commitment to sustainability not only benefits the planet but also resonates with a growing number of environmentally conscious consumers.

Challenges and Future Prospects

Despite their successes, metal roof cutting machine factories face several challenges. The rapid pace of technological advancement necessitates continuous investment in new machinery and employee training. Additionally, global supply chain disruptions can impact the availability of raw materials required for machine production.

Looking ahead, the prospects for metal roof cutting machine factories appear promising. With advancements in technology such as artificial intelligence and automation, the potential for enhanced efficiency and precision in cutting operations continues to grow. As the construction industry increasingly embraces these innovations, the demand for superior metal roof cutting machines is likely to rise.

Conclusion

In summary, metal roof cutting machine factories are pivotal in shaping the construction industry's future. By providing essential equipment that enhances efficiency and precision, these factories are not only helping to create resilient and sustainable roofing solutions but are also contributing to economic growth and job creation. As technology continues to advance and environmental considerations gain importance, these factories will play a crucial role in driving innovation and progress within the industry. The future is bright for the metal roof cutting machine sector, and its impact will continue to resonate across various construction landscapes.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025