Advanced Metal Roof Cutting Equipment for Precision and Efficiency in Roofing Projects

The Advancement of Metal Roof Cutting Machines Revolutionizing the Construction Industry

In the realm of modern construction, efficiency and precision have become indispensable virtues. As projects demand faster turnaround times and higher quality results, innovations in technology have emerged to meet these needs. One such innovation is the metal roof cutting machine—an essential tool that has transformed how metal roofing is fabricated and installed. This article explores the features, advantages, and impact of metal roof cutting machines on the construction industry.

Understanding Metal Roof Cutting Machines

Metal roof cutting machines are specialized tools designed to cut metal sheets and panels with precision and ease. These machines come in various forms, including portable handheld units, stationary band saws, and advanced CNC (Computer Numerical Control) routers. Each type serves different purposes and is suited for various applications, ranging from small-scale residential projects to large commercial roofing endeavors.

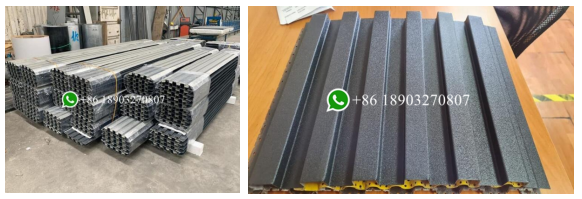

The primary function of these machines is to produce clean, accurate cuts in metal roofing materials such as steel, aluminum, and copper. Equipped with sharp blades and advanced cutting technology, they can handle various thicknesses and types of metal, making them versatile for diverse construction needs.

Features of Modern Metal Roof Cutting Machines

Modern metal roof cutting machines boast several advanced features that enhance their performance and usability

1. Precision Cutting Today's machines are engineered to deliver precise cuts, minimizing material waste and ensuring that the finished product fits perfectly. CNC machines, in particular, employ computer software to guide the cutting process, achieving high levels of accuracy.

2. Speed and Efficiency With advanced motors and blade designs, these machines can cut metal sheets rapidly. This efficiency significantly reduces the time required for roofing installation, allowing contractors to complete projects faster.

4. User-Friendly Controls Most modern machines come with intuitive control panels, making them easy to operate even for those who may not have extensive experience with metalworking tools.

metal roof cutting machine

5. Safety Features Safety is paramount in construction; thus, many machines incorporate features such as blade guards, automatic shut-off mechanisms, and emergency stop buttons to protect users during operation.

Advantages of Metal Roof Cutting Machines

The introduction of metal roof cutting machines has brought about numerous advantages for the construction industry

1. Cost-Effective By minimizing waste and reducing labor costs through quicker installation times, these machines can lead to significant savings for contractors and homeowners alike.

2. Better Quality Control With more precise cuts, the quality of the finished roof improves, enhancing durability and aesthetic appeal. This attention to detail helps in avoiding costly repairs and replacements in the future.

3. Versatility Metal roof cutting machines can process various types of metal and are adaptable to different project sizes. Whether it's cutting custom shapes for aesthetics or standard panels for efficiency, these tools can handle it all.

4. Reduced Labor Intensity By automating the cutting process, less manual labor is required, reducing the physical strain on workers and allowing them to concentrate on other essential aspects of the project.

5. Environmental Benefits Efficient cutting processes reduce material waste, contributing to more sustainable construction practices. Additionally, many machines are designed to work with recyclable materials.

Conclusion

In conclusion, metal roof cutting machines represent a significant advancement in the construction industry, enhancing precision, efficiency, and quality in roofing projects. As technology continues to evolve, we can expect further innovations in cutting technology that will enable even more sophisticated applications. For contractors, builders, and homeowners, investing in a metal roof cutting machine can lead to considerable advantages, ensuring that projects are completed on time, within budget, and to the highest standards. As the demand for metal roofing continues to rise due to its durability and aesthetic appeal, the metal roof cutting machine is poised to remain an invaluable asset in the modern construction landscape.

-

Roof Panel Machines: Buying Guide, Types, and PricingNewsJul.04, 2025

-

Purlin Machines: Types, Features, and Pricing GuideNewsJul.04, 2025

-

Metal Embossing Machines: Types, Applications, and Buying GuideNewsJul.04, 2025

-

Gutter Machines: Features, Types, and Cost BreakdownNewsJul.04, 2025

-

Cut to Length Line: Overview, Equipment, and Buying GuideNewsJul.04, 2025

-

Auto Stacker: Features, Applications, and Cost BreakdownNewsJul.04, 2025

-

Top Drywall Profile Machine Models for SaleNewsJun.05, 2025